Some Important Things To Consider While Operating Melt Flow Index Tester

Melt Flow Index Tester works as a backbone for the manufacturers of the plastic industry as it is the basic machine which is used to test the quality of the plastic granules that finally defines the quality of the materials. Certain things need to be considered before commencing the test procedure on Melt Flow Index Tester so that the user can get accurate test results.

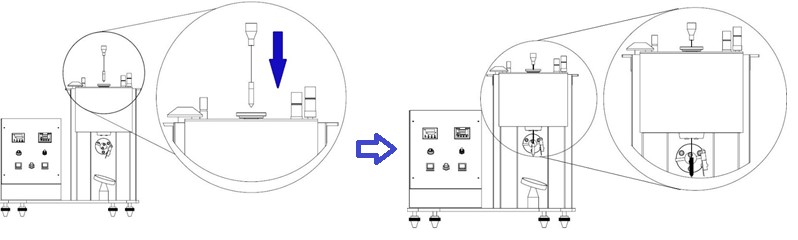

1) Leveling of the Machine Before the Test

Leveling of the machine should be done before starting the test procedure so that the user can get accurate test results.

- For checking the leveling of the machine, use the plumb line provided with the machine

![]()

- Take out the orifice die from the machine and insert the plumb line inside the barrel.

- Now check the perpendicularity of the plumb line related to the ground.

- If the plumb line is perfectly perpendicular to the ground, this means the machine is perfectly leveled.

- If the plumb line is slightly deflected from the perpendicular direction, this means the machine needs leveling.

- Level the machine by aligning the footrests.

This process can help you to perform the Melt Flow Test. After performing the test, it is necessary to clean the barrel firmly so that next test with a different type of granules can be carried out for accurate results. This will also help you to maintain your device for a long and efficient usage.

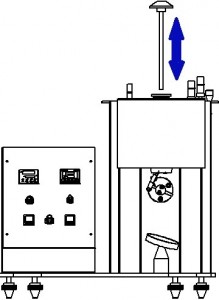

2) Cleaning of Barrel After the Test

- After the test has been completed for one material and there is another material to be tested, it is essential to clean the barrel and the orifice properly for accurate test results.

- For cleaning of barrel and orifice, increase the temperature greater than the melting point of the material on which the test was conducted. The temperature should be increased at least 10o C to 15o This will help in loosening the material that is stuck on the barrel walls or the die orifice.

- After increasing the temperature, wait for three to five minutes.

- Now use the flat and threaded cleaning tools provided with the machine to clean the barrel and cavity of the heating cylinder.

- After that, the orifice cleaning tool should be used to clean the die or orifice from the bottom of the barrel.

- Once the cleaning is done, the test can be commenced for another material.

This process will help you to maintain your instrument for a long and help you to test different types of granules with accurate results again and again. For technical information visit: Melt Flow Index tester.

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free CopyNeed more information

Connect with us for your business enquiries. Generally we respond within one or two working days.

send enquiriesContact Us

Quick quote