Working Procedure Of MFI Tester To Measure The Viscosity Of Polymers

Why Melt Flow Index of Plastics is Measured?

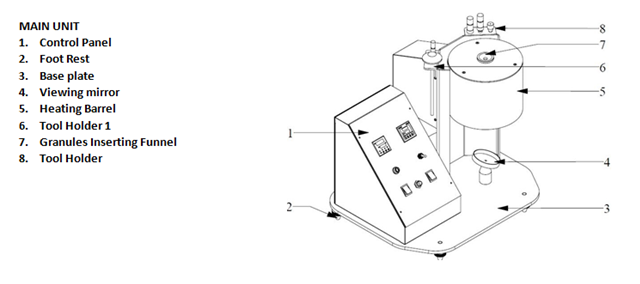

The plastics are used in a significant number of applications to produce industrial and domestic goods. The manufacturers of plastic product need to analyze the quality of the plastic materials to make sure the best quality of products they provide to their clients. The Melt Flow Index is a major property of the plastics that determines the physical as well as chemical properties of the materials. Melt flow index tester is an advanced testing machine that is very helpful in the accurate analysis of the Melt Flow index of plastic granules of different types of plastics.

Presto Stantest understands the need for measuring properties of polymers and offers high-quality of Melt Flow Index Tester. The machine is designed with a PID controller that is best for controlling the temperature inside the chamber with high accuracy. A timer is also provided along with the machine which can be used for setting the testing time up to 999 hours.

On the other hand, it is also true that without following a proper working procedure, a manufacturer cannot able to test the quality of the polymers easily and efficiently. But this also can be done by following a standard operating procedure. Presto’s Melt Flow Index Tester is designed as per the standards ASTM D1238.

Standard Operating Procedure As Per the Standard

Plug in the main switch of the machine to commence the test. The PID controller of the instrument will show some value on the Digital panel in PV (Process Value) and SV (Set Value) both. Now set the operation of the machine to manual or automatic using the toggle switch which is provided on the control panel. Now set the required temperature and time and on the heater by pressing the heater switch on from the control panel. Now wait until the present value reaches the set value. After the required temperature is attained as set in the device, fill the barrel with the plastic granules. Now push the granules with the help of a plunger which is provided with the machine to insert the granules in the machine in order to eliminate the air gap between the granules. You will examine a slight decrease in the present value on the digital indicator. Now again wait until the PV value reaches SV. Make sure that the granules are preheated before starting the test. One the PV and SV value become same. Place the plunger inside the barrel along with the dead weight on it.

This process will let the extrudate come out of the orifice or die which is assembled at the lower end of the machine. Ignore the first sample that comes out of the orifice and consider the melted samples or extrudate that comes afterwards. Take the weight of the sample using the digital balance. This will be used to calculate the Melt Flow Rate of the Polymers.

Formula to Calculate the MFI of Polymers

Melt Flow Index of Polymers = Weight of Melted Samples in Grams

10 minutes

If you want to buy Presto’s Melt Flow Index tester to test the quality and viscosity of Polymers, Contact Presto.

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free CopyNeed more information

Connect with us for your business enquiries. Generally we respond within one or two working days.

send enquiriesContact Us

Quick quote