Wall Thickness Measurement Using Non- Destructive Technique

Non-Destructive testing technique is the best strategy which is adopted by numerous glass bottle manufacturers nowadays, to measure the thickness of the bottle’s wall without deforming their shape and size. If you are looking for high-quality wall thickness gauge, Presto’s Magnamike 8600 is the best instrument for you. It is an innovative test device which is used to measure the wall thickness of all types of bottles without disturbing the shape, size and appearance of the bottle.

Working Principle of Presto’s Magnamike- 8600

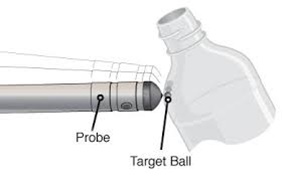

Magnamike 8600 works on the Hall’s Effect Principle. It is a product by Olympus. Presto is an authorized dealer of Magnamike. The instrument comprised of a small steel ball and a magnetic probe. The steel ball is inserted inside the container or ball, and the magnetic probe is placed on the outer surface of the sample, correspondent to the sample. The device measures the difference between the probe and ball and displays the thickness of the bottle wall on the screen.

Application of Magnamike 8600

Magnamike 8600, wall thickness gauge is used to perform non-destructive testing for large number of applications such as:

- Plastic Bottles or Glass Bottles

- Packaging Containers

- Automotive Tear Seams

- Aerospace and Other Applications

For detail information on Magnamike 8600, contact our team of experts.

you may also like

- Safeguard Sensitive Products from Repetitive Movement by the Vibration Table

- Eliminate Excessive Moisture by Measuring It with the Moisture Meter

- Determine the Mechanical Properties of Plastic Materials with the UTM Machine

- How to Conduct Tensile Tests & Calibration on the Tensile Strength Tester?

- Evaluate Pressure Sustainability of Packets & Pouches with Vacuum Leak Tester

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free Copy

Quick quote