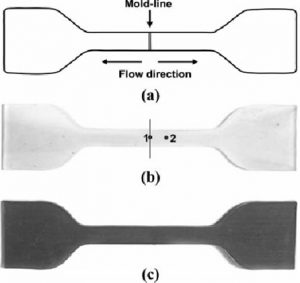

Testing the behaviour under different circumstances is noteworthy for engineering design. In plastics industry, every shape is designed after thorough study. Every cut, ridge, curve, etc. have some significance in the plastic model. For example, if you see a PET bottle, it has a base with some depth. It is not merely a design, it is there to provide stability for bottle balancing. Every millimetre of this depth is measured. The designer cannot randomly select any size and shape for moulding. If we talk about flexible plastic, you must have noticed that some plastics tend to stretch while other may fail when subjected to stretching. The plastic film is an example of this. ASTM D638-01 is an international standard released by American Organization. In this standard, they have defined the clear conditions under which sample is tested.

Some highlights;

Why there is a need to do tensile strength test?

Plastic undergoes a different type of environmental and human generated conditions like temperature, humidity, movements, impacts, jerk, etc. When plastic is used at a domestic level like for making control bodies, mobile phone bodies, plastic furniture, toy rides for kids, crockery, jars, bottles etc. plastic is subjected to external forces, both compressive and tension. To check the longevity of the product when a tension is exerted on it, tensile strength testing is performed. For instance, when a plug is pulled out from the socket, a force is exerted on the screw holes. In this scenario, screw holes must be able to bear the tension. A manufacturer can never predict the conditions in which his product will be used. But yes, he can manufacture things where he knows the intended condition in which product can withstand. With appropriate testing, he can prepare a set of instructions to be passed to the intended user.

How can the Tensile test be performed?

In this test, you will be applying outward force on the sample. What is the maximum force it can bear without breaking is the tensile strength of the sample? Presto Group offers a Tensile testing machine to perform this test.

This machine has two lead screws having a movable plate attached to it. Two jaws having grips are attached to the movable plate and to the anvil. Depending upon the type of sample, a grip can be chosen. What is noteworthy here is that this machine is a universal machine, can be used to tensile testing and compression testing. It has the capability to accommodate different types of grips which make is multipurpose for different industries and different applications. You can choose the mode whether it should operate in tensile mode or compressive mode. When chosen in the tensile mode the movable plate will start moving in an upward direction until the sample fails. As soon sample fails, the plate will stop from moving further. How much applied by the machine to break the sample will be displayed.

Special features:

Applications of Universal Testing Machine

So, far we were talking about the tension mode of the Computerised universal testing machine, some spotlight will be shed on other applications.

Since it’s a universal machine it can also be used for testing compressive strength of the sample. What makes it useful for other industries is the wide variety of grips. The standard grip comes along with machine is perfect to clamp plastic and rubber. However, there is a wide variety of grips that can be bought if applications are wide. Vice type grip, self-tightening grip, flexural grip, roll type grip wedge type grips are easily available with this.

This machine can be used in plastic industry, rubber industry, metal industry, packaging industry, automotive industry, aerospace industry. To know more information about its features, price, and technical specifications, give us a call at +91 9210903903 or email us at info@prestogroup.com.

Connect with us for your business enquiries. Generally, we respond within one or two working days.