Non-Destructive testing is the process of examining, testing and estimating the properties of the materials, components to ascertain the differences in the characteristics such as shape, size, thickness and many more without disturbing the serviceability or actual shape of the product. On the other hand, after the test is performed on the material, the material can still be used. In comparison to NDT testing, all other tests are usually destructive in nature and therefore can be performed on a limited number of samples as these cannot be used further.

All the destructive types of tests are performed on the materials to determine the properties of the materials such as ductility, yield strength, tensile strength, impact resistance, fatigue strength, toughness but the differences in the material characteristics, shape, and thickness can only be determined efficiently by means of NDT testing.

Nowadays, modern ways of non-destructive testing are used in all manufacturing industries, fabrication industries and in during the time of service and inspection to ensure the product’s reliability and ductility that helps to control the manufacturing process, lower down the cost of production and maintain the uniformity in the quality of the products. At the time of manufacturing of the products, NDT testing is used to ensure the quality of the raw material, and help to consider the joining process efficiently at the time of erection and fabrication process. On the other hand, NDT testing at the phase of service and inspection is considered to ensure the usefulness of the product and its safety to the public.

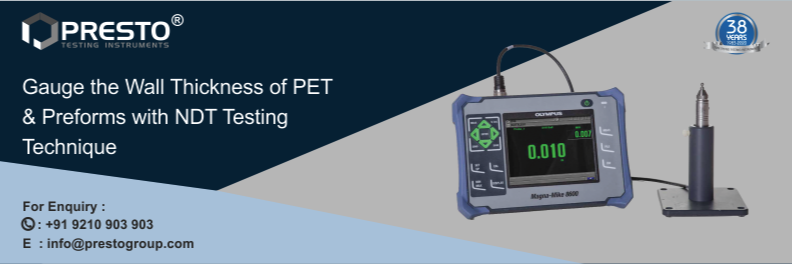

The most common testing device which is used to perform NDT testing is Magnamike 8600 – Wall Thickness Gauge. It is a premium quality of product introduced by Olympus. Presto is an authorized dealer of Magnamike. The instrument is used commonly in PET & Preform industries to measure the evenness of the walls of non-ferrous materials such as plastics, preforms, PET, glass bottles, tanks, aluminum products and many more without distorting the actual shape and size of the product. The instrument works on the Hall Effect Technology

Connect with us for your business enquiries. Generally, we respond within one or two working days.