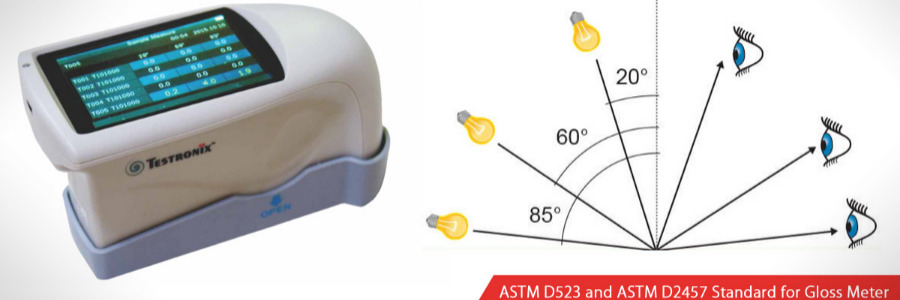

The ASTM D523 test method explains the measurement of gloss on non-metallic samples for geometries of 20, 60 and 85 degrees. The ASTM D2457 standard test method is used to measure the gloss of solid plastics and plastic films (opaque and transparent both).

There are four separate gloss angles for the different specimens, such as 60° for intermediate gloss films, 20° for high-gloss films, 45° for intermediate and low gloss films, and 75° for plastic siding and soffit.

How is Gloss Measurement done?

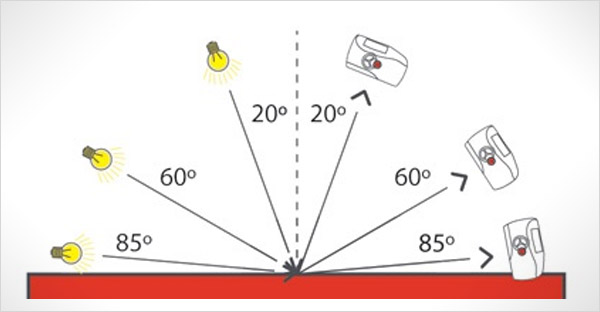

The specular gloss measurement is performed for the light reflected from the material surface. The gloss is the result of the moulding process and can be inherent to the material. The gloss is significant for product and process development as well as for performance testing. The angle of reflection that is 20°, 60°, and 85° must be specified for the gloss measurements. The proper angle, calibration, and inspection according to standard supplied with the gloss meter are important before placing the measuring device on the test sample to take a reading.

Gloss Meter Tri-angle for that perfect Gloss Evaluation

The Gloss Meter Tri-angle is used to perform the gloss measurement of various types of materials such as paint, paper, ceramics, plastics, and metals. The compact and portable instrument measures the geometry 20°, 60° and 85°. The tool has extensive use for measuring the surface quality and shining complying with the international standards of ISO2813, GB/T 9754, besides ASTM D523, ASTM D2457.

Key Features:

• Capacitive touchscreen featured

• Software-based output of test results

• Simultaneous measurement by triple standard angles- 20°, 60°, and 85°

• Aesthetic design with ergonomics structure

• Display multiple sets of data for easy and quick comparison

• USB communication interface

• User-friendly data management allows user to check, delete, export or print record

• Protective cover for the measuring aperture

• Print facility available (through software program)

• Option for export to pdf & word file for all test results

• Statistical model to display deviation, conclusion, diagram area etc. of test records

• Portable with handy battery available for traveling purpose.

Related Blogs

Hot Air Oven uses dry heat for sterilizing glassware and metal tools, while an Autoclave uses steam under pressure—ideal for liquids and medical items.

GSM of fabric (Grams per Square Meter) indicates fabric weight and thickness. Higher GSM means denser, heavier fabric; lower GSM means lighter, thinner fabric.

Discover why abrasion resistance is crucial for packaging, textiles & plastics. Learn how it's tested (Martindale, Taber, DIN) & why it boosts durability. Save costs with wear-resistant materials!