Friction is something we encounter every day—whether it’s the grip of your shoes on a wet floor or the smooth slide of a package along a conveyor belt. But how do we measure it? That’s where a coefficient of friction tester comes into play. This tool helps industries and researchers figure out how much force it takes for one surface to slide over another. It’s a simple concept with big implications, especially in packaging, manufacturing, and material science. In this blog, we’ll dive deep into what a coefficient of friction is, how these testers work, the formulas behind them, and what makes static and kinetic friction different. Plus, we’ll touch on what affects the price of these testers. Let’s get started!

First things first: the coefficient of friction is a way to measure how much grip or slip happens between two surfaces. Think of it as a score that tells you how tough it is to slide one thing over another. We call it “mu” (μ), and it’s just a number—no fancy units—because it’s a ratio of forces. Friction itself is the push-back you feel when you try to move something, and the coefficient tells you how strong that push-back is.

There are two flavors of friction to know about: static and kinetic. The coefficient of static friction is about getting something to budge when it’s sitting still—like shoving a heavy couch across the floor. The coefficient of kinetic friction kicks in once it’s moving, showing how much effort keeps it sliding. These numbers aren’t always the same for the same materials, and that difference matters a lot depending on what you’re working with.

A coefficient of friction tester is a machine designed to measure these friction values accurately. Imagine a setup where you’ve got a flat surface, like a table, and a block or “sled” that slides across it. That’s the basic idea. Here’s how it works step by step:

The beauty of this setup is its simplicity. Whether you’re testing a slick plastic film for packaging or a rough rubber surface for tires, the process stays the same. The tester just mimics what happens in the real world when two things rub against each other.

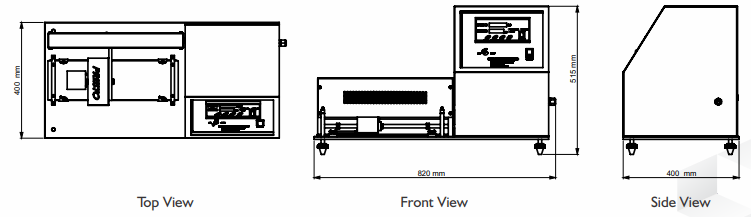

A Coefficient of Friction Tester diagram typically illustrates key components such as the friction table, test sample, sled, load sensor, and digital display. It shows how the sample moves against a surface under controlled force, measuring both static and dynamic friction to ensure material quality and performance in various industries.

Now, let’s talk numbers. The coefficient of friction formula is straightforward:

μ = F / N

For static friction, F is the maximum force needed to start the sled moving. For kinetic friction, F is the average force required to keep it sliding smoothly. Since both F and N are forces, the units cancel out, leaving μ as a plain number—usually between 0 and 1, though it can go higher for very sticky surfaces.

Here’s an example: If a sled weighs 10 newtons and it takes 5 newtons of force to start it moving, the coefficient of static friction is 5 / 10 = 0.5. If it takes 3 newtons to keep it sliding, the coefficient of kinetic friction is 3 / 10 = 0.3. Simple, right?

So, what’s the difference between static and kinetic friction? It’s all about motion—or the lack of it.

Think of it like this: Static friction is the stubborn gatekeeper, while kinetic friction is the gentler usher guiding things along. A coefficient of friction tester measures both so you know exactly what to expect in different situations.

These testers are a big deal in industries like packaging, automotive, and construction. Here’s why:

The data from a tester isn’t just numbers:—it’s a roadmap for making better, safer, and more efficient products.

If you’re thinking about getting one of these machines, the price can vary a lot. Here’s what drives the cost:

Prices can range from a few hundred dollars for a simple manual tester to thousands for an advanced, automated system. It depends on what you need it for—hobbyists might go cheap, but industrial users often invest in the good stuff.

Here’s a quick look at some common material pairs and their friction coefficients. These are rough averages—actual values depend on surface conditions like roughness or moisture.

| Material Pair | Static Coefficient (μ_s) | Kinetic Coefficient (μ_k) |

| Wood on Wood | 0.5 - 0.7 | 0.3 - 0.5 |

| Rubber on Concrete | 0.6 - 0.9 | 0.5 - 0.7 |

| Plastic Film on Steel | 0.2 - 0.4 | 0.1 - 0.3 |

| Steel on Steel (Dry) | 0.7 - 0.8 | 0.4 - 0.6 |

| Glass on Glass | 0.9 - 1.0 | 0.4 - 0.5 |

A coefficient of friction tester is more than just a gadget—it’s a window into how materials behave when they rub against each other. By measuring static and kinetic friction, it gives us the numbers we need to design better products, ensure safety, and streamline processes. The formula is simple, the process is practical, and the insights are powerful. Whether you’re curious about how it works or wondering about the price tag, it’s clear this tool plays a big role in our world. Next time you slide something across a table, you’ll know there’s a science—and a tester—behind it!

Get premium-quality Coefficient of Friction Testers at competitive prices from Presto Group. Our advanced testing equipment ensures accurate friction analysis for packaging, plastic films, and other materials, helping you comply with industry standards.

Call Now: 9210903903

Email Us: info@prestogroup.com

Get the best coefficient of friction tester price today! Contact us now for details!