Our Valued Clients

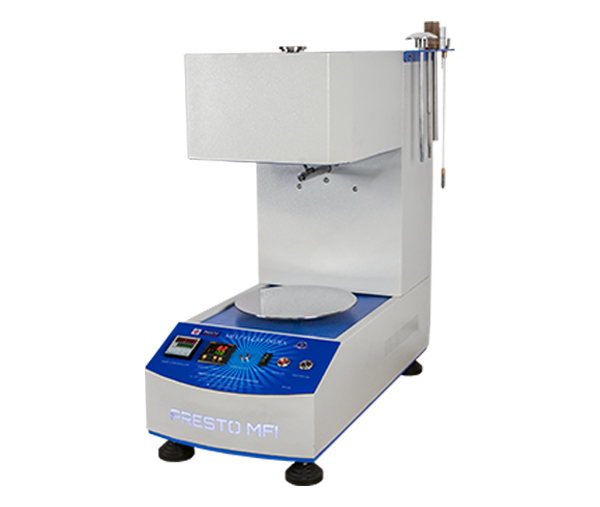

Presto Melt Flow Index Tester is used for evaluating the flow properties of molten plastics or resins. The Melt flow Index of thermoplastic materials is defined as the rate of flow (in grams per ten minutes) of extrudates of molten resins through a jet of a particular length and diameter.

The Presto Melt Flow Index Tester - NXG Model is a reliable instrument used for evaluating and analyzing the flow properties of molten plastics or resins. The determination of the melt flow index of plastic materials is an important parameter in the evaluation of its quality.

If you are working in the plastics or polymer industry, then you should be aware that it is important for manufacturers to test the melt flow rate of these materials. The melt flow rate of the materials is considered to be the measure of the flow of polymers when it will be melted. The result of the melt flow rate will be reported as the weight of the polymer that will flow through the orifice in a certain period of time.

The melt flow rate of the polymers is one of the essential properties of the materials that will help the manufacturers in determining the rate at which it flows. This property of the material is important as it provides the necessary data on the mass flow rate of the polymer. Thus, to test the melt flow properties of the materials, we at Presto have recently designed a high-quality Melt Flow Index Junior model.

The new-design MFR Model can quickly extrude the flow rate of molten resins utilizing the advanced setup of load, piston, and a metallic barrel. The specimen, majorly in granule form is put inside the barrel and the piston is inserted. Loads, as per requirement are placed on the piston and the parameters are then selected from the touchscreen display.

The Tensile testing Machine is highly recommended for evaluating the tensile strength of products and materials. The equipment is based on the Constant Rate of Traverse (CRT) principle. It is equipped with an upper jaw and a lower jaw. Universal Tensile Testing Machine is a reliable piece of equipment which is widely used for checking tensile strength of a product/sample. One of the most common mechanical testing techniques used to determine tensile strength, this is a method wherein controlled tension is applied to a sample until it fully fails.

Thus, the material properties of the sample can be easily determined by this test. It involves measuring the force required to elongate a sample under test to breaking point. Using this test, manufacturers and quality managers are able to determine the core strength of their products.

Registered Design Patent No. 252611

Availability: In stock

The Presto Tensile Testing Machine is based on the Constant Rate of Traverse (CRT) principle. During the test, the sample is held between two jaws. The upper jaw is stationary, while the lower jaw is made to move at a designated fixed speed with the help of a motor.

Tensile testing is an important process for evaluating the strength, ductility, and toughness of materials. By determining a material's Young's modulus, tensile testing can also provide information about a material's stiffness.

Presto comes with a new model of tensile testing machine with a COF tester. This testing machine is well designed with industry standards like ASTM D618, ASTM D 883, BS 2782, and ASTM D 1894. With the help of this testing machine, you can easily measure the tensile strength along with the co-efficient of friction of various products like plastic films, sheets, and rubber and paper.

Tensile tests are commonly used to measure the mechanical properties of plastics. The force required to break a plastic sample specimen is an indication of the material's strength, while the extent to which the specimen stretches or elongates to that breaking point provides information about its ductility.

The Presto Ultra Low Temperature Deep Freezer is equipped with an air cooled compressor and CFC free refrigerators. These systems are installed to provide efficient cooling and consistent flow in the cabinet.

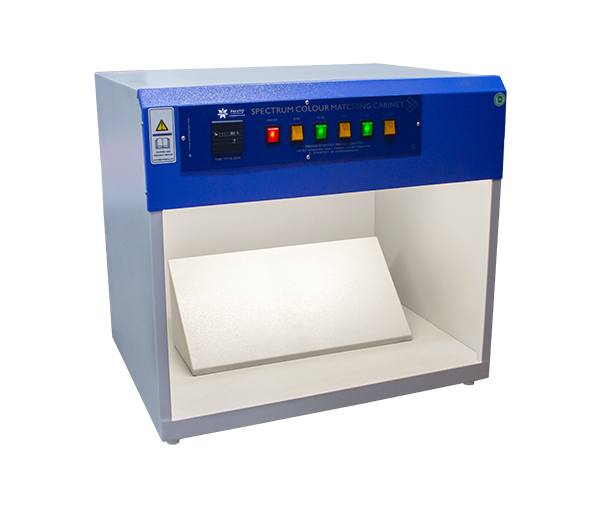

The Presto Color Matching Cabinet Spectrum Asia II is one of the widely used lab testing instrument in the industries and laboratories where it is important to maintain the color consistency of the products. This color matching machine will provide accurate assessment of colors under standardized environment for evaluation and visual assessment of colors.

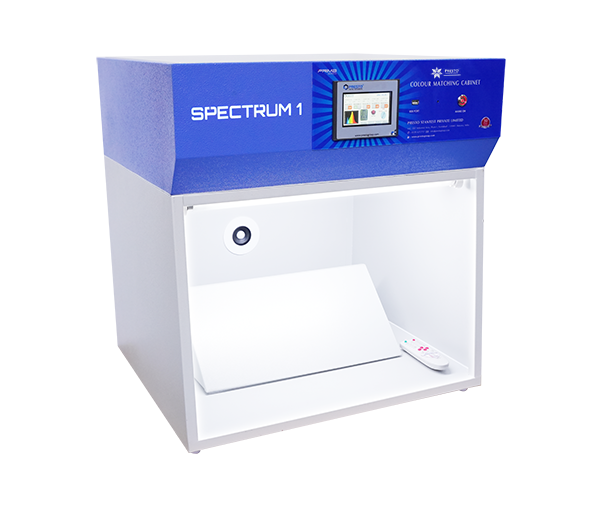

Presto Color matching cabinet- Spectrum I Prima series has been designed to match the consistency of colors present in the product. This quality lab testing instrument has been designed accurately with correct light types and thus allows direct comparison of products that must have special color characteristics. Users will get five possible lighting types embedded in this testing instrument. These colors are supplied as standard: "D65", "TL84, "UV", "CWF" and "TFL”.

.jpg)

The Farbung TP110 is a highly used and preferred color measurement instruments in many industries. There are several new features that are added to the product by the highly competent team of engineers and scientists of Presto Stantest.

.jpg)

TP310 is a prominent color measurement instruments used in many mainstream industries which have been designed and manufactured by competent engineers and scientists of Presto Stantest. The instrument has many advantages of other international standard color measurement instruments.

Heat Deformation - HDT/VSP Tester is a consistent tool useful for determining the ability of a given polymer to bear load at elevated temperatures. Accurate and reliable deflection or deformation is an important component in the plastics industry.

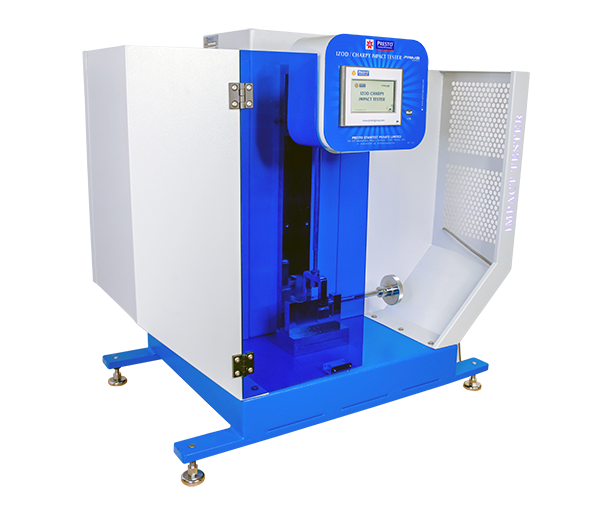

The PRESTO IZOD/CHARPY IMPACT TESTER has been designed for assessing the impact resistance of plastics. Operated on the pendulum method principle, this equipment serves as a reliable instrument to gauge the impact resistance of materials when subjected to sudden falling force or impact. Users can accurately conduct charpy and izod test on the materials and ensure that accurate products will be delivered to the customers. The IZOD/Charpy Impact Tester stands as a consistent and indispensable testing equipment for accurately measuring the capacity of materials to withstand impact, contributing valuable insights into their durability and structural integrity.

In stock

The IZOD/Charpy Impact Tester is a reliable and consistent testing instrument that is used for measuring the impact resistance of materials under sudden falling force or impact. Presto has designed a high-quality IZOD/Charpy Impact Tester NXG model that will easily reveal the impact strength of plastics and other related materials.

Identifying the strength and durability of materials is of utmost importance to make sure that quality products will be delivered to the customers. Thus, if you are looking for a highly accurate lab testing instrument to identify the sturdiness of materials under sudden falling force or impact, then you must go with Presto Izod / Charpy Impact Tester Computerized model.

The PRESTO notch cutter is used for making a notch in the Izod / Charpy samples as per ASTM D 256-10, ISO 180. It is a sample preparation machine that prepares the sample for Izod Tester to test the plastic sheets.

Presto Carbon Black Dispersion Test Apparatus is mainly used for the determination of carbon black dispersion. It finds wide application in the plastic industry. The instrument comprises of a hot plate for sample placement.

Presto Carbon Black Content Apparatus is commonly used for determining the Carbon Black content in polyethylene and polypropylene materials. The test is applicable only to samples where carbon is present in a free state.

The Specific gravity of any elastomer is of considerable importance for its identification and can also be used for providing a rough assessment of its physical properties.

Humidity Chamber - Touch Screen with Data Logger is used for assessing the change in physical properties of the materials when there is a severe change in the environmental conditions like humidity. The machine is equipped with advanced touch screen panel and upgraded features. It comes with 3 coloured tower style alarm to alert the operator.

Humidity/Conditioning Chamber is a unique test cabinet designed to create temperature and relative humidity inside the chamber to detect the change in the physical characteristics of material and to ascertain the actual working life of testing device. PRESTO humidity chamber is designed as per standards ASTM D1776, ASTM D1776M-15.

Programmable Temperature & Humidity Test Chamber is the latest technology designed for evaluation of material, product and component's behaviour and its tolerance level in harsh weathering conditions including temperature and humidity.

Vibration simulation is an efficient and cost-effective way of determining damage caused by the repetitive movement in the vehicles. In just a few hours we can pinpoint potential damage areas in your package or product caused by vibration.

Our Vibration Table is customizable. You can get a Digital, Computerised, or touchscreen Vibration table according to your sample testing needs! Be it swivel, synchronous, or asynchronous, test your sample to its fullest to ensure durability, long life, and zero rejections.

Availability: In stock

Environmental Stress Cracking Resistance Tester is a unique test cabinet designed to detect the change in the physical characteristics of the plastic material and to ascertain the actual working life of test samples at environmental stress.

The Presto muffle furnace is used to determine the ash content of a specimen. The percentage of ash in a material gives important insights into the properties of the substance. The Presto muffle furnace is specially designed as per IS & ASTM Standards.

Presto's Muffle Furnace - HMI Prima series is used to measure the percentage of ash content in a particular specimen. The percentage of the ash in a sample offers vital insights into the properties of the material.

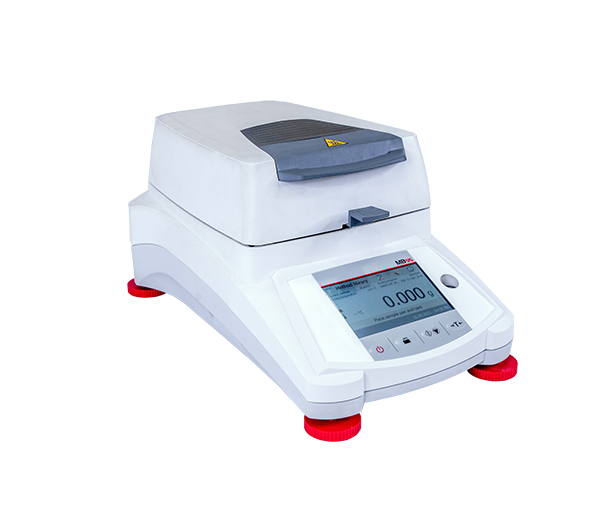

The MB95?s halogen heating system distributes heat uniformly over the sample and speeds up the drying process ? delivering fast and precise measurements.

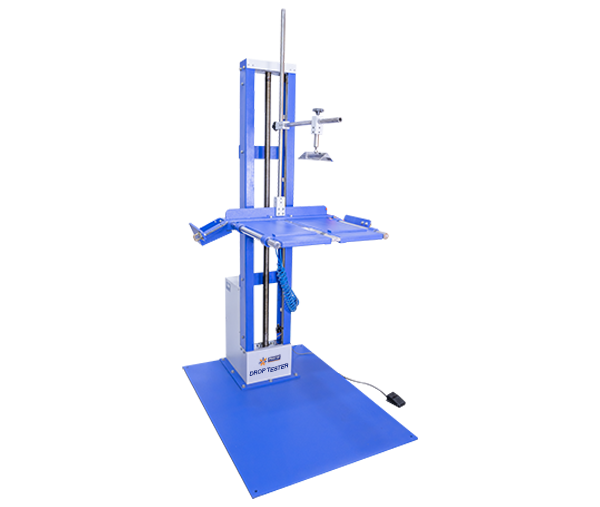

The Drop Tester (As per IS:7028 Pt IV) is a useful equipment for ascertaining the transport worthiness of corrugated & solid fiber boxes and shipping containers. It has provision with angular drop arrangement to help accurately ascertain the transport worthiness of the package from all angles.

In stock

Drop tester is the perfect machine to test the drop strength of the corrugated cartons. It is equipped with a wired remote-control mechanism to eliminate the human interference. The test specimen is observed visually after it is made to fall from a certain height. The instrument work with pneumatic application and used in almost every industry that deals with corrugated cartons.

The Presto grammage checking kit comprises of the GSM round cutter along with Digital weighing balance. GSM round cutter with imported industrial blades gives you a very accurate & seamless cutting of your samples.

.png)

The Presto Dart Impact Tester is used for determining the impact of a free falling dart on a plastic film. The energy of the falling dart causes the film to fail under specified conditions. The dart has a hemispherical head and is held by a strong electromagnetic dart holder.

In stock

Presto's Dart impact tester - HMI is a high-quality testing instrument, used in different packaging industries, to measure the strength of the plastic films to withstand the various forces levied on it. The instrument is provided with an electromagnetic...

Magnamike, manufactured by Olympus, is a premium-quality device renowned for its excellence in conducting wall thickness gauge testing. Offering a non-destructive testing method, this instrument is ideal for measuring the wall thickness of PET bottles. Presto Stantest serves as an authorized dealer for this device.

In stock

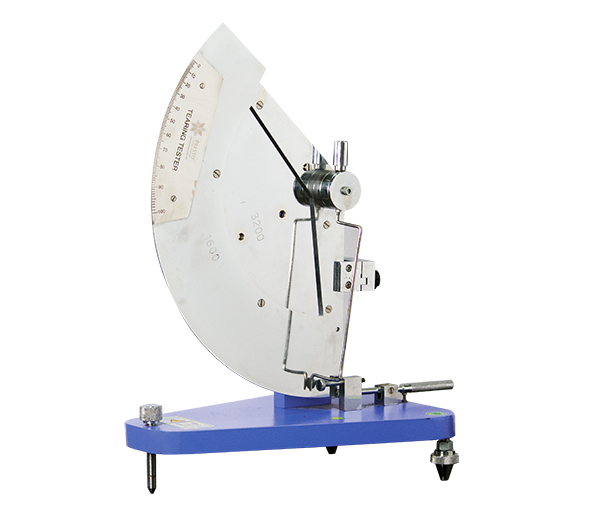

Tearing Strength Tester is a consistent tool useful to determine the tearing strength of fabrics, plastic films, and similar materials. Tearing Strength Tester is the tensile force required to rupture a pre-slit sample under controlled test conditions.

Tearing Strength Tester is a consistent tool useful to determine the tearing strength of fabrics, plastic films and similar materials.

Presto has recently launched a tearing strength tester HMI model that is manufactured in a state-of-the-art lab and is designed for the tearing resistance of paper, thin film, ventilation tape, and other materials. We have designed our equipment to make advanced calculation methods that make sure precision test with reliable repetition. The equipment is installed with a high-speed programmable logic controller system that provides features such as auto testing, calculation, and analysis result.

Heat Sealer Prima is a consistent tool used to perform sealing on flexible packaging products and other thermoplastic materials using pressure and heat by maintaining high temperatures. A heat sealer is used to measure the heat seal performance of composite films.

Availability: In Stock

Shipping Area: Throughout the world

Heat Sealer is a consistent tool used to perform sealing on flexible packaging products and other thermoplastic materials using pressure and heat by maintaining high temperatures.

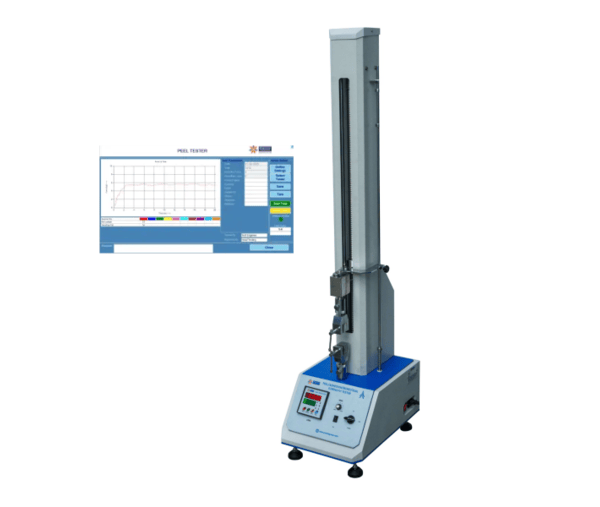

Presto Adhesion Strength Tester is used to quantify the permanence of adhesion or peel ability of self- adhesive pressure sensitive materials. Peel adhesion is defined as the force required for removing a pressure sensitive coated material.

Peel Bond Strength Digital Tester is a standardized test machine, which is widely used to conduct accurate peel/seal strength test for adhesive materials. Suitable for measuring the stability of adhesives like tape or glue, it is a reliable quality control equipment. It is used for checking the ability of the sample to get peeled off from a surface. The testing equipment is designed and manufactured according to ASTM D903 standard.

Presto Peel Strength Tester has a display screen which is based on a hi-tech microprocessor that converts force applied into numeric values. So, the peel adhesive strength value that is measured can be directly viewed on the screen. Application force is controlled uniformly; this is done in order to ensure equal distribution of pressure, all over the test sample.

Registered Design No. 361206-003

Availability: In stock

Peel Adhesion/Bond/Seal Strength Tester is a consistent tool to quantify the permanence of adhesion or peel ability of a self-adhesive pressure sensitive materials. Used for checking the Peel, Adhesion, Bond, Seal Strength testing for Plastic Films and Foil.

Coefficient of Friction Tester is a consistent tool to indicate the starting and sliding friction of plastic films and sheets when sliding over itself or other substance at specified test condition.

Registered Design Patent No. 341519-003

The coefficient of Friction Tester - Digital Cum Computerised is a consistent tool to indicate the starting and sliding friction of plastic films and sheets when sliding over itself or other substance at specified test condition.

Flammability Tester (UL94) is a smart testing apparatus which is utilized to conduct the Standard test for ensuring the Safety of Flammability of Plastic Materials which are used for Parts in Devices and Appliances.

Flammability testing determines how easily a material or finished product will ignite or burn when exposed to or used near fire or heat. Flammability testing covers several different testing protocols and methods intended to measure a material's vulnerability, including its susceptibility to an ignition source, its propensity to combust, and the rate at which it will burn when ignited. The Tester is based on IS 15061, The standard is applicable to check the burning behavior (ignitability, burning rate and melting behaviour) of interior materials used in motor vehicles.

Hot Air Oven is a unique test cabinet designed to detect the change in the physical characteristics of the material and to ascertain the actual working life of testing device at elevated temperature. Works on Forced air circulation, thermal convection principle, suitable for Tests like heat deformation, compression set, heat resistance required in rubber and plastic industries.

Hot Air Oven - Touch Screen is a time-tested instrument to assess the change in physical properties of the materials with the change in temperature. This is an advanced model with complete touch screen control and upgraded features. It comes with 3 colors tower style alarm to alert the operator.

(1).png)

Elevated temperatures can have a significant impact on the physical properties of many materials. Either it can deteriorate the quality of the product or will lead to product damage. This can have a major impact on the performance of products and structures made from these materials. Thus, it is important for product manufacturers to test the physical properties of the materials at elevated temperatures so as to determine their quality.

Balloon Burst Tester - Balloon Burst Test is a seal integrity test wherein an empty 3 side pre-sealed pouch is clamped on the 4th open side and air injected into it. The Presto balloon burst tester comes with a single push-button operation, making it easy to use and control. This testing instrument will automatically lock the sample under test within the selectable pressure range, eliminating the need for manual intervention.

Polymer products usually damage when exposed to various environmental conditions which are formed from the atmosphere. This directly affects the actual life of the product. Hence, it is necessary to test the quality of the polymers to calculate...

The gloss meter is available in different geometries to measure the specular reflection gloss of a surface or a material. The Gloss Meter Tri-angle is used to determine the gloss on a surface and measures the amount of reflected light.

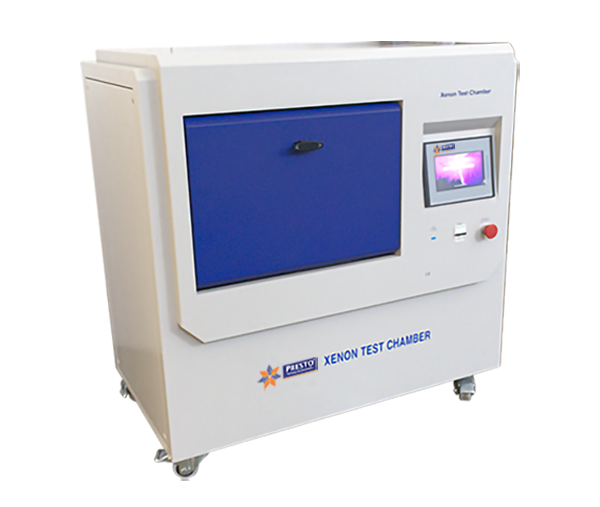

Presto offers different types of environmental testing instruments to create actual weather conditions of various kinds. One of the best environmental test equipment introduced by Presto is Xenon 866. The test equipment helps to examine the weather resistance...

Polymer materials are usually get damaged due to the natural environmental factors which form due to the atmosphere and earth's surface when it is used for years outdoor which directly affect the life of the products.

Presto's Hot Tack Tester is an extremely effective testing machine which is used to perform hot tack test and check heat seal performance of laminated films, plastic films, and other packaging products.

Punctures Testers are widely used to evaluate the rupture or puncture characteristics of a material. This is done by performing a compression test on a material, where the compression is done with the help of a probe...

Presto's Profile Projector is robust measuring testing equipment which is widely used in PET & Preform Industries, quality assurance departments, machine shops and also in industrial testing laboratories.

Illuminated Inspection Magnifier is a consistent tool that helps the manufacturer in testing the small components or parts using a magnified glass. It uses a convex lens tho obtain magnified image of the object.

Presto is best manufacturers, suppliers, and exporters of high-quality Plastic testing instruments all over India. We introduce a distinguished collection of laboratory testing equipment. We design and manufacture our machines using the ultra modern developing unit, superb quality of resources and latest technology with defined quality standards. We highly believe in producing quality products to assure our clients that our laboratory plastic testing instruments are excellent in terms of quality and durability that provide accurate results.