When organic contents of a material are burnt down, the left behind is ash. It is the inorganic content present in any material. If any material is heated to its burning point in presence of oxidizing agents, only ash is left behind. To assess the quality of a material, it is very important to assess the presence of inorganic components. There are different processes defined to measure the ash content in the food products, and they are;

.jpg)

The test method is selected based on the application of the material, requirements of the sample, specifications of the sample. These test processes also help in analysing the minerals present, as they can be easily differentiated.

In the food industry, to ascertain the quality of food, different tests are performed. Nowadays, ash testing is catching up the trend as it tells a lot about the quality. Minerals present in the material can also be assessed with this test. According to the regulatory authorities, the presence of ash up to 5% is acceptable, more than this helps in determining the age of the food.

How to Prepare Samples?

To perform the ash test, preparing the sample is a crucial part. The food sample has to be in powdered form. Any moisture content present is dried first and it would lead to sprinkling during heating. Fatty food samples leave moisture when dried which prevents spattering. Another major problem is contamination of sample due to surroundings or due to the container used for holding the sample. The weight of the sample has to be in-between 1 to 10 gms.

By leveraging the advancement in the technology, smart analytical instruments are introduced in the market that does not require processing of sample before testing. They are equipped with decision-making circuits to dry out the moisture first and then change it into ash for analysis, using very high-temperature range.

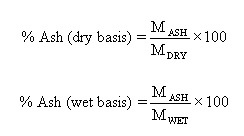

The difference in weight before and after the test is the percentage of ash content.

Where,

MASH = Mass of the ash sample,

MDRY = Refers to the mass of the dried sample.

MWET = Refers to the mass of the wet sample.

If you are looking for Muffle Furnace Price then you can consult with us. We are considered to be the leading Muffle Furnace manufacturers that will provide you with high quality testing instruments to ensure zero rejections rates from your customers.To know more information about its features, price, and technical specifications, give us a call at +91 9210903903 or email us at info@prestogroup.com.

Connect with us for your business enquiries. Generally, we respond within one or two working days.