Presto’s Salt Spray Chamber is the best and widely used testing instrument which helps to measure the effect of elevated temperatures on the physical, chemical and mechanical properties of the painted and metal substrates. The device is designed in strictly in compliance with various national and international standards such as ASTM B117, DIN 51121, JIS Z2371, IS 5528, IS 6910, ISO 3768. When talking about the accuracy of the machine, certain things need to be considered. Out of these, calibration of the machine plays a significant role.

Why is it necessary to calibrate a salt spray chamber?

As per the highly standardized testing procedure, it is necessary to ensure that the salt spray chamber has the ability to create correct conditions and the same time, it is necessary to ensure that the test which is carried out in the chamber must meet the requirements of relevant standards as well.

When the need for calibration of Salt Spray Chamber does arise?

- The need for calibration arises when the user is about to perform the test on the machine after a long nap of time.

- When it is required to repair, maintain and transport the salt spray chamber.

- Also, the need for calibration arises when the user found that the results are improper.

How Presto’s Salt Spray Chamber can be Calibrated?

The instrument can be calibrated in four parts:

Calibration of Temperature Value of Chamber

1. To perform the same put the PT 100 sensor in the chamber and close the canopy

2. If the Temperature SET value of the chamber is 35o, then the device is calibrated and if it is above or below 35o, perform certain steps:

a. Go to “Main Menu” of the HMI Screen.

b. Enter default password “1111.

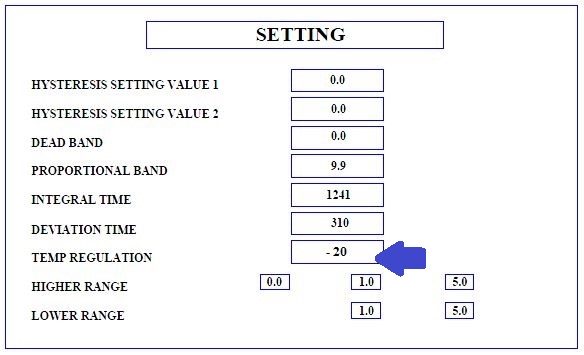

c. Now click on Setting and setting screen will appear with various options.

d. Click in “Inner Chamber PID Setting” and the screen will appear.

e. Now click on “PID & Hysteresis setting” option and a screen will appear.

f. Go to “TMP” option and enter 20 numbers for 35-degree temperature.

g. Now your device is calibrated.

3. If the temperature set value of the chamber is 37o (above the calibrated temperature), set the value of the “TMP” 20 numbers with the “(-) minus sign” and your device will be calibrated.

Calibration of Air Saturator Temperature

- First of all, put the probe i.e. PT 100 sensor inside the air saturator.

- Now verify the PV value of the air saturator with the master. If it is 45o, then the device is calibrated.

- If the PV value of the air saturator is below 45o, i.e. 43o perform following steps:

a. Go to “Main Menu” of the HMI Screen.

b. Enter default password “1111”. Click on Settings option.

c. Now Setting screen will appear with various options.

d. Click in “Air Saturator PID Setting” and the screen will appear.

e. Now click on “PID & Hysteresis setting” option and a screen will appear.

f. Go to “TMP” option and enter 20 numbers to calibrate the value to 45-degree.

g. Now your device is calibrated.

4. If the temperature Process value of the chamber is 47o (above the calibrated temperature). Set the value of the “TMP” 20 numbers with the “(-) minus sign” and your device will be calibrated.

Pressure Gauge Calibration

- Add Master Pressure Gauge in the series line of the Main Pressure Gauge.

- If the value is correct, the pressure gauge is completely calibrated.

- If the value is out of tolerance, change the pressure gauge.

Time Calibration on Screen through Stop Watch

- Start the stopwatch and compare the timings at the time of the screen.

- If the time of the machine is in the limit, then it is OK. Otherwise, perform real-time clock setting.

All the four steps of calibrations help to calibrate Presto’s Salt Spray Chamber completely.