The paints and coating are used on a large number of products to enhance the elegance and appearance of the products. Various types of coatings such as varnish, paint, conversion coatings and other paint products are usually subjected to the different types of damages during the manufacturing process and its use. Therefore, it is necessary to test the impact resistance of paints to determine its strength and quality.

To measure the strength and quality of the paints and coatings, various standards have been introduced by the standardization authorities such as ASTM D 2794, ASTM D609. These standard test procedures are introduced for rapidly deforming the coating or paints by providing impact forces to evaluate the effect of deformation on the materials.

How to Perform the Impact Test?

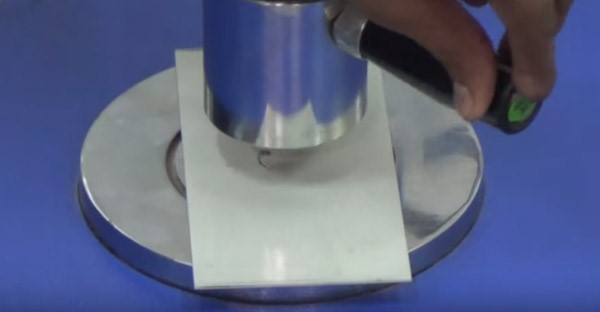

The organic coatings that are placed under test are coating on thin metal plates and placed to perform four or more test to measure the results accurately. After the effect of impact forces, when the coating curved, a standard amount of weight is dropped from a height to strike the material that deforms or destroy the coatings and the material as well. The indentation can be either extrusion or intrusion. Steadily increasing the distance, drop down the weight from generally 1inch or 25mm at a time so that the quality of the material can be determined from the set point at which machine is set and failure occurs.

Get detail technical guidance from experts, click here and contact our team.

Types of Impact Test

There are two kinds of test that are performed to determine the impact resistance of paints:

In both the test methods, the damage which is caused by first observed thoroughly and the quality is then evaluated. These highly standardized methods are used to measure the performance of paints and coatings under quick deformation process.

Paint Impact Test

Paint Impact test is a highly conventional, well-known test which is used to characterize the quality of the paints, varnishes, and coatings that are applied to different types of coatings, substrates, composites under defined operating conditions. In the conventional laboratories, tests dynamic forces are implied on the metal coated substrates to determine the impact resistance strength of the paints.

Different types of coating impact test allow applying different impact forces with different frequency, weight and number of impacts to test the quality of a thin coated metal substrate. The behaviour of the impact on the materials is then presented in the form of graphs and digital readouts to define the critical force clearly.

Want to achieve high impact resistance for your product? Click here to reach the team of experts.

Paint Impact Testers by Presto

Presto offers a high-quality testing machine to perform impact resistance of paints by means of Direct Paint Impact Tester and Indirect Paint Impact Tester. The test on the coatings is performed using these testing machines to determine the crack formation, adhesion, and elasticity of the paints, breaking strength of the paints and coatings. After performing this test, a bulge is formed in the metal sheet by a falling weight with a hemispherical end. This helps to determine the quality of the paints as well as the metal sheets.

The Presto’s Impact Resistance Tester for Paint are designed as per the standards

ASTM D2794-93(2010), ISO 6272-1:2011 to impose a direct impact on the mildly abused products in offices, households, laboratories, and offices.

Key Features

For more information or to get a quote on Impact Resistance Tester, contact our team.

Connect with us for your business enquiries. Generally, we respond within one or two working days.