The speed of corrosion reaction on metal substrates is highly dependent on the environment. Various environments where coated metals are used are classified as per the reduction in the thickness or mass of the metals and metal alloys when they are subjected to different atmospheric conditions. As per the standard EN ISO 12944-2 -1998, the atmospheric conditions that corrode the metals are:

| Industrial Atmosphere | Marine Atmosphere | Country Atmosphere | |

| Pollution | High Pollution | Low Pollution | Hardly Any Pollution |

| Wet Time | Long Wet Time, High Humidity | Varies from low to high | Low Wet Time |

| Rate of Corrosion | Corrosion Rate of Zinc Plating >1.5 μm/year | Varies with Temperature, Wet Time and Relative Humidity | Corrosion rate of zinc often< 0.4 μm/year |

| Content of Salt in Atmosphere | High Content of Salt | High Content of Salt | Low Content of Salt in Atmosphere |

Types of Corrosion & Preventions

The mentioned environmental factors affect corrodes the metals with different types of corrosion. Some types of Corrosion are mentioned below:

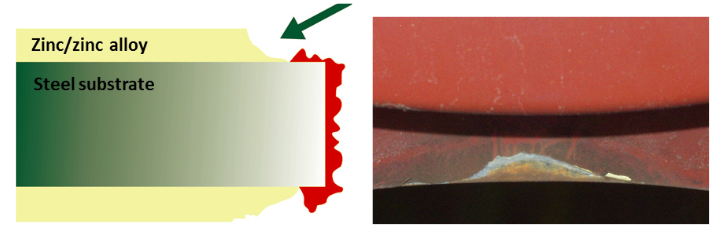

Prevention – The highly effective way to prevent the edge corrosion is a paint layer after cutting the material.

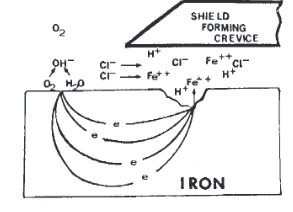

Prevention – This type of corrosion can be treated by ensuring the quality of the plating or coating so that the crevice will not form between the substrate and the coating.

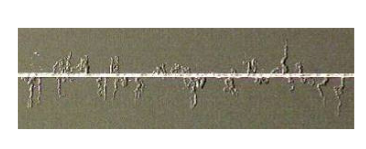

Prevention – This type of corrosion can be treated with the coating with very low moisture permeability. Zinc coated steel is also less prone to this kind of corrosion defect.

Apart from this, various types of corrosion are there that damage the quality of the metal substrates.

How can the Resistance of Plating to Corrosion be detected?

Although there are so much of preventions to the corrosion, still it is quite difficult for the manufacturers to ascertain that how much a metal substrate is resistant to corrosion? But this can be tested only when the material is subjected to different atmospheric conditions for a specific period of time to evaluate the actual working life of the material during their actual usage. This can be done only with the help “Salt Spray Chamber”.

The instrument is designed as per standard ASTM B117. According to this standard, the device is capable enough to create a salty environment, high temperature from ambient to 45 degree C, humidity, and moist conditions inside the chamber. The device is used to set the time of device for specific days and hours in order to ascertain the effect of different atmospheric conditions in years. This also ensures that the instrument will offer precise test results. Read more about this at Salt Spray Chamber.

Connect with us for your business enquiries. Generally, we respond within one or two working days.