With the day-by-day increasing requirement of rubbers in manufacturing houses, the need for testing also increases with the higher rate to analyze the properties of the rubbers efficiently. The quality of the rubber goods has a significant effect on the quality of the final products, and it is also responsible for the safety of the user. Therefore, it is necessary to test the quality of the rubber goods to enhance the quality of the end products. To test the rubber materials, various types of tests are conducted on the rubbers. But to perform the test in the highly effective manner, it is essential to prepare the test sample in best and appropriate way.

How the Accuracy of Samples can be Determined?

To perform the tests in highly effective manner, it is also mandatory to ensure the accuracy of the samples. The accuracy of the sample can be determined by the shape and size of the sample to that the test can be performed in the highly standardized manner, and there with be maximum chances to get accurate results. If these samples are not prepared with accurate dimensions, definitely there will be variations, in the end, results. This will clearly indicate that the samples are not designed as per the standards, and there will be a change in the results from sample to sample.

One Stop Solution of Sample Preparation

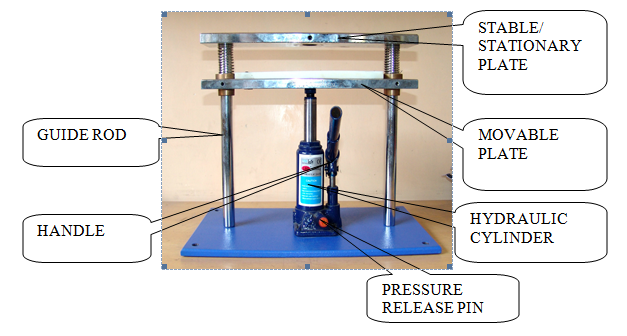

The best testing machine which is used to prepare the samples is Dumbbell Cutting Press. The testing machine is mainly used in rubber industries to cut the samples of appropriate shape and size. Presto offers highly accurate and premium quality of Dumbbell Cutting Press that helps to cut the samples of appropriate dimension, size and shape.

Presto’s dumbbell cutting press is an extremely accurate testing device that helps to a cut a sample of standard size in dumbbell shape from a piece of material. This dumbbell shaped sample is used to perform various tests like flammability, tensile, compression and many more tests. The instrument offers highly standardized-shaped test specimens that strictly adhere to various national and international standards like ISO, ASTM, BIS, etc.

Technical Specification of Presto’s Dumbbell Cutting Press

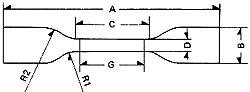

The die is made from high quality die steel to give long lasting finish and accuracy. The die is hardened & tempered and is zinc plated for corrosion free usage. Standard Size supplied: 115 mm Cutting Press to be bought separately. The shapes & dimensions of dies for preparing dumbbell specimens shall conform to standards. The inside faces of the reduced section shall be polished and perpendicular to the formed by the cutting edges of a depth of at least 5mm. The dies shall be sharp and free of nicks in order to prevent ragged edges on the specimen.

How to Operate the Machine?

To operate the machine as mentioned in the standards, perform the following steps:

This process helps to prepare the sample of the exact shape and of best dimensions. For more information on the instrument, visit: www.prestogroup.com/

Connect with us for your business enquiries. Generally, we respond within one or two working days.