Dart impact test is performed on plastic films and laminates to determine the effect of free falling dart on plastic films. The energy created by the falling dart causes the film to fail under some specified conditions. The test is widely performed by the manufacturers in plastic industries and paper & packaging industries to assess the durability and strength of the plastic films and other related products.

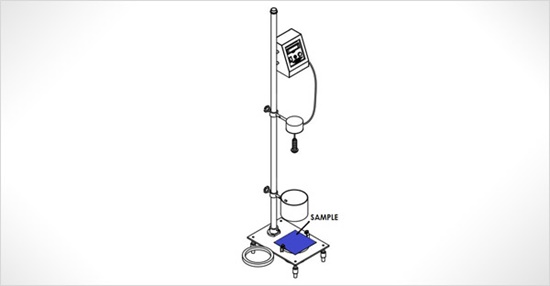

To perform the impact test using the Dart Impact Tester, first of all, the user need to prepare the test sample as per the standards for precise and reliable results. This includes certain steps.

Preparation of Test Specimen

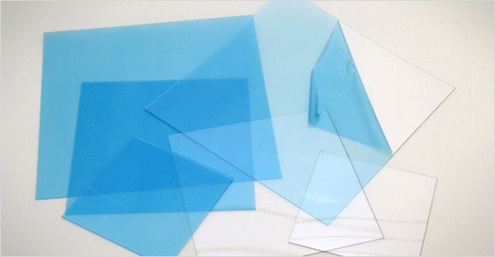

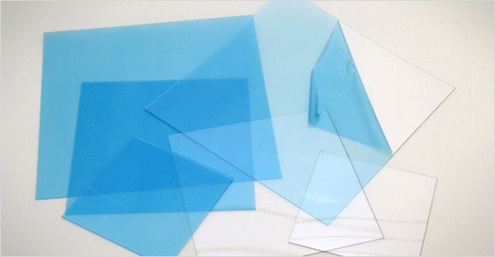

As per the Standards ASTM - D 1709 - 15a, ASTM - D 3029 - 82a, IS - 2508 - 1984, to prepare the specimen to perform the Dart Impact Test efficiently using Dart tester, you need to follow certain steps:

- Measure the thickness of the test sample in the area of the impact to the nearest 0.002mm.

- Take at least five measurements with the help of a suitable thickness gauge.

- Find the means of all the five values and record the thickness of the sample easily.

- Test Specimen need to be large enough to extend beyond the specimen clamping ring by at least 25mm at all the points. The specimens must be the representative of the film under study and shall be taken from the sheet or tube in such a manner, so that whole of the sheet is represented in the test.

- The specimen needs to be clamped by the specimen holder ring.

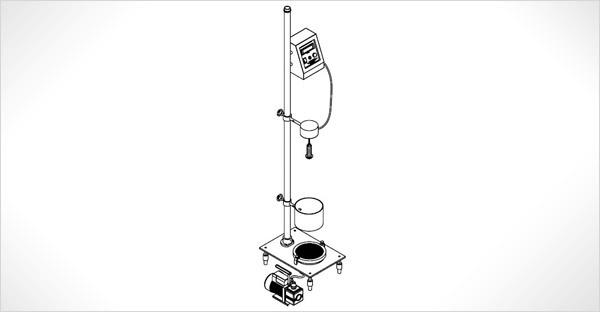

- Do not forget to connect 6mm pneumatic pipe from the vacuum pump.

- Power ON the vacuum pump so that the sample will be held due to a vacuum pump and it will be ready for testing.

Points to be considered before implementing the Test Procedure

- Check whether you have adjusted the level of the machine with the spirit level or not.

- Lock the leveling bolts in the perfect position and ensure that the apparatus does not vibrate.

- Do not forget to connect the power supply cord of the device to a 3 pin 5-ampere socket on a single phase 230V AC supply line.

- Ensure the proper earthing connection of the socket outlet.

- Ensure the location of the release mechanism of the vertical channel support.

- The dropping height of the dart of 660mmcan be attained by fixing the drop height in the middle set of holes.

- To set the height of dart at 1524mm, fix it in the upper most holes

Note: If the release mechanism is not fixed in the desired position, simply remove it from the present position and reaffix it at the desired one.

SOP – Dart Impact Test on Plastic Films

As per provided ASTM and IS standards, after choosing appropriate sample and after adjusting the height of the drop as per the standards and application requirement,

- Select appropriate weight of the dart, which is nearest to the expected impact failure weight.

- You can also add required number of incremental weights to the dart shaft and put the locking collar in its place in order to set the weights in a particular location.

- Place the first test sample from the top of the clamp ensuring that it is uniformly flat and wrinkle free and overlaps the clamp by about 25mm on all sides. Hold the sample firmly. Put on the vacuum pump to adjust the sample to get stretched and for the wrinkle free and fold free sample.

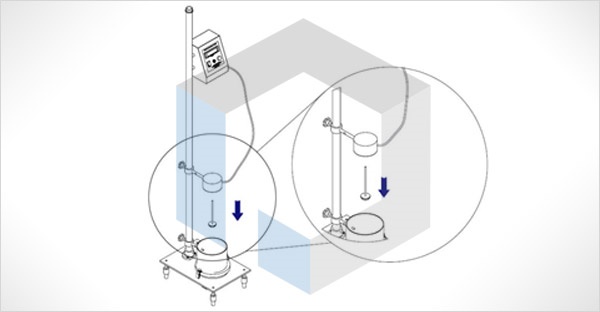

- After the sample is held firmly in the clamp, place the upper tip of dart in the center hole of the electromagnet and keep it pressed in an upward direction.

How to take the exact reading of the Scale?

To perform the test, fix the electromagnet clamp / holder at different length of 660mm & 1524mm with the given formula:

Scale Length + Dart Length + Electro Magnet length = Reading of Scale

For example:

- If the length of scale is 660,

660mm + 212mm + 35mm = 907mm

- If the length of the scale is 1524mm,

1524mm + 226mm + 35mm = 1785mm

- Now press the push button on the side of the channel to activate the electromagnet.

- Now release the push button to enable the dart to fall on the centre of the specimen which is held in the clamp.

- Examine the test sample to determine whether it has failed or not.

- If the sample failed, reduce down the weight and if not failed, then take fresh test sample to perform the test with the enhanced weight.

- Repeat the process until the sample fails at least 50%.

Formula to Calculate the Impact Resistance

Impact Resistance = M100 – D (S1/100 – 0.5)

Where,

M100 = lowest weight according to the D used at which 100% failure occurs.

D = Uniform increment weight used (in grams)

S1 = Result (Percentage Failure) – Sum of Percentage of breaks at each weight.

For example,

| Weight |

No. of Test Samples Taken |

Result (Percentage Failure) |

Number of Samples Broken |

| 90 |

10 |

0 |

0 |

| 105 |

10 |

10 |

1 |

| 120 |

10 |

20 |

2 |

| 135 |

10 |

60 |

6 |

| 150 |

10 |

100 |

10 |

| |

|

= 190 |

|

Impact Resistance = 150 -15(190/100 – 0.5) = 129 grams

Where, D = 15 (uniform incremental weight)

If you are looking for Dart Impact Tester Price then you can consult with us. We are considered to be the leading Dart Impact Tester manufacturers that will provide you with high quality testing instruments to ensure zero rejections rates from your customers.To know more information about its features, price, and technical specifications, give us a call at +91 9210903903 or email us at info@prestogroup.com.

.png)