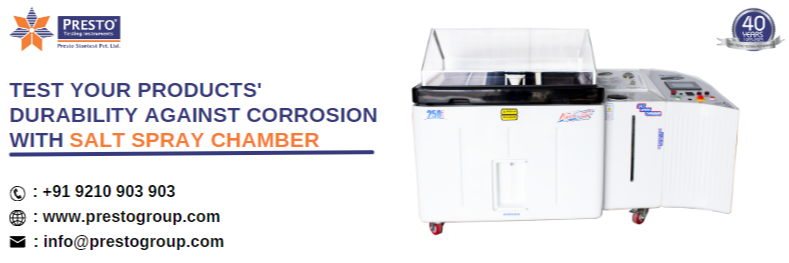

We all know that corrosion can cause significant damage to products, which can lead to safety hazards, functional issues, and decreased product lifespan. Thus, testing the corrosion resistance of metals is important to ensure that quality materials will be delivered to the customers. We at Presto have designed a high-quality lab testing instrument known as the Salt spray chamber- Korrox IV Magnus Series.

This is one of the high-quality lab testing instruments that is used to conduct salt spray tests on the materials and ensure that quality products will be delivered to the customers. In this blog, we are going to discuss brief information about the Presto salt spray testing chamber and how this quality testing equipment is used to test the corrosion resistance of metals. But before that, let us discuss the impact of corrosion on metal components.

Impact of Corrosion on metal components

Corrosion can have a significant impact on metal components, causing them to deteriorate over time. Corrosion can also cause metal components to lose their dimensional accuracy, leading to issues with fit and function.

It is important for metal product manufacturers to test the impact of corrosion on metals so that the components will not get deteriorate over time. The Presto Salt Spray Chamber - Korrox IV Magnus Series Computerized is powerful testing equipment that can be used to evaluate the corrosion resistance of coatings when exposed to salt-laden environments.

This quality lab testing equipment is highly useful in testing the corrosion properties of the materials and ensures that surface coatings of metals will not deteriorate before time.

All about Presto Salt Spray Chamber - Korrox IV Magnus Series Computerized

The Presto Salt Spray Chamber - Korrox IV Magnus Series Computerised is a state-of-the-art laboratory testing instrument that is designed to test the corrosion resistance of various materials. This testing chamber is built with high-quality materials, and an HMI touchscreen is embedded to view the testing results more precisely.

This computerized version of the salt spray testing chamber is equipped with a user-friendly control panel that allows for easy programming and monitoring of the test parameters. This chamber also features a built-in data logging system that records and stores test results for analysis and documentation.

This quality lab testing instrument is suitable for a wide range of applications, including testing of metallic coatings, electroplating, paints, and other materials. The chamber conforms to various international standards, that will ensure accuracy in test results.

Now, let us discuss brief information about the features and technical specifications of this quality testing equipment.

Features of Presto Salt Spray Chamber - Korrox IV Magnus Series Computerized

- HMI-based Touchscreen Model

- Inbuilt temperature settings

- Salt Spray Test mode enabled setting parameters according to the test sample

- Corrosion Resistant PT-100 sensor

- Solid-state digital Programmable Temperature Controller

- Program profile for selecting test parameters and performing the test.

- Easy Data Management. Users can create PID settings, Air Saturator settings, test temperature, test and air purge time, etc.

- Current test running status display

- Robust Construction with Fiber reinforced body(Triple wall)

- Ease of use of sample placements inside the test chamber

- Pneumatically operated canopy (only for 250 Ltr. Model)

- Air purge after the test for fog settlement.

- Reservoir Tank inside sponge filter with low solution level alarm.

- 5-point Auto Tuning feature selection

- Real-time vs temperature graph

- Data recording with a temperature data reading

- USB option available (Pen drive is not a part of supply)

- Users can control PID settings through the Advanced Hysteresis setting

- The angle of the Canopy was maintained in order to restrict the flow of droplets directly on the test sample.

- Low-compressed air alarm (Smart device introduce)

- Low NACL solution alarm.

- Over / under voltage protection

- Individual specimen real-time monitoring with identification.

- Maintain fault history (Easy to Diagnostic the exact issue)

Technical specifications of Presto Salt Spray Chamber - Korrox IV Magnus Series Computerized

- Display: HMI Based touchscreen 7" TFT LCD Color screen

- Chamber Temp Range: Ambient to 40ºC

- Test Chamber Temp. working Range: 35ºC ± 2ºC

- Chamber Temperature Least Count: 0.1ºC

- Chamber Temperature Repeatability: ± 2ºC

- Air Saturator Temperature Range: 40ºC- 49ºC

- Air Saturator Temperature Least Count: 0.1ºC

- Air Saturator Temperature Repeatability: ± 2ºC

- Power: 220V, Single phase, 50 Hz, 15A

- pH value of Salt Solution: 6.5 to 7.2 pH

- Temperature Control: Inbuilt PID Temperature Controller

- Timer(Hour meter): 6 digits

- Test Air Pressure: 0.7Kg/cm² - 1.2Kg/cm²

- Air Regulator: 0 to 30 psi

- Compressed Air requirement: Approx. 7 cfm (Air Compressor not part of supply) Main airline pressure regulator with filter in customer scope.

With these high-end features and technical specifications, one can easily

conduct salt spray tests on the materials and ensure quality products are delivered to the customers. You can give us a call at

+91 9210 903 903 or email us at

info@prestogroup.com to know more about the price of this quality testing equipment. Besides this, you can also take free sample testing sessions for this quality testing equipment.