- /

- Blog / ASTM D4086 Standard Test Method For Assessment Of Metamerism

ASTM D4086 Standard Test Method For Assessment Of Metamerism

Different pigments, colorants, and dyes are used to make the same color match that results in metameric color. The customer does not require the products in metameric color (nonmetameric). The ASTM D4086 standard test method is applicable to perform the testing procedure in the field as well as the laboratory. The nonmetameric matches cannot be practiced due to the costing or other reasons. Some limitation of metamerism is required, which is assessed by the test method.

- The test method includes the visual methods to detect the metamerism to estimate the magnitude of a metameric color difference.

- The test method is not applicable for geometric metamerism and is limited to consider the illuminant metamerism and observer metamerism.

- The test method does not categorize the metamerism based on instrumental measurement of spectral features.

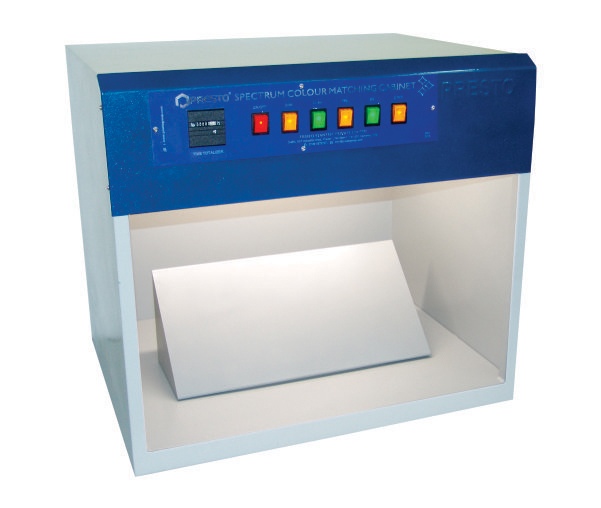

Visual Color Matching Cabinet Beneficial for Metamerism

Presto designs and manufactures the visual color matching cabinet to check the color consistency in various products. The change in color appearance under different lights is resolved with the instrument. The equipment is recommended to use in laboratories and industries where color consistency is a crucial part. The device creates a consistent environment to evaluate the visual assessment of color.

Metamerism poses a problem where the color of the test sample appears different under different light sources. The visual color matching cabinet is efficient to solve the issue of metamerism and allow to check the actual color quality of the products. The equipment is recommended for the paint and plating industry, besides textile & yarn, plastic, paper and other areas.

Recent Blogs

- Controlled Humidity Chamber: Environmental Testing Methods, Applications & Packaging Testing Use Cases

- Spectrophotometer & Portable Spectrophotometer: Working Principle and Laboratory Applications

- Paint Tester & Coating Testing Equipment: Types, Testing Process, and Industrial Applications

- Moisture Meter: Types, Working Principle & Applications in Industrial Labs

- Environmental,Pharmaceutical, and Research Laboratories in BOD Incubator