- /

- Blog / Bottle Burst Tester: Pressure Strength Testing of PET and Plastic Bottles

Bottle Burst Tester: Pressure Strength Testing of PET and Plastic Bottles

If you are a manufacturer, retailer, or any other person concerned about the market, you may have noticed that in recent times the demand for PET products, especially plastic bottles, has increased drastically, even though the world vows to lead a plastic-free society. Why so? There is nothing as versatile and affordable in the world that can replace PET and plastic products. Leave the old money alone; even newer entrepreneurs are opting for PET and plastic products, with some exceptions opting for materials like mud, clay, and bamboo. Whatever the scenario depicts, there is one common mishappening that stings every manufacturer in the PET and plastic products industry. That is the bottle burst scenario. Neither the manufacturer nor the end customers want to experience something like this. And for that, the manufacturers have to implement the PET bottle burst test every time they make a bottle.

What Is a Bottle Burst Tester?

Many times, during different circumstances, it happens that the PET bottles burst. Sometimes, due to the lid being too tight, and several times due to several hot or cold temperatures. So that it does not happen, products like beverages like soda, beer, or sparkling water are usually packed in tin cans.

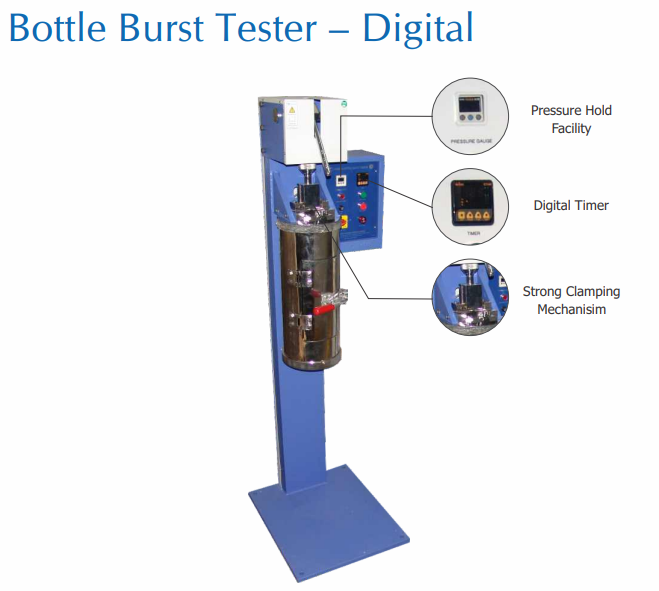

But not everything you can pack in tin cans. To escape such scenarios, manufacturers use the bottle burst tester, which is designed to measure how much pressure a bottle can tolerate before failure. The process involves filling the target product with air or water, gradually increasing pressure until the bottle bursts. The data recorded shows the maximum pressure the bottle can handle and highlights weak areas in design or material. In products like soft drinks, edible and body oils, and the chemical packaging industries, where safety and product integrity are essential, the PET bottle burst test is necessary.

How Does the PET Bottle Burst Test Prevent Such Bad Luck?

What does the PET bottle burst test do? makes sure bottles are strong enough to handle pressure before they reach customers. It recreates real conditions, spots weak areas, and checks durability. By catching defects early, it helps prevent leaks, bursts, and unhappy buyers.

- Detects weak spots or thin walls in bottles

- Ensures bottles withstand required pressure levels

- Prevents bursting during storage, transport, or usage

- Enhances safety and brand trust by delivering reliable products

Thus, this test acts as a quality safeguard, minimising risks and confirming consistent PET bottle performance.

How Does a Bottle Pressure Strength Tester Work?

By applying controlled pressure inside the bottle, the bottle pressure strength tester works. The machine applies controlled pressure inside the bottle and checks whether it can resist bursting or deformation. The procedure involves the followings:

- Fixing the bottle securely inside the chamber.

- Filling it with compressed air or water.

- Increasing internal pressure gradually until the bottle deforms or bursts.

- Recording the maximum strength value.

Why Is a Slip Resistance Tester Used Alongside Strength Tests?

While strength test checks how much internal pressure or external force a bottle made of PET or plastic can handle, the slip resistance tester rather finds out the grip of the outer body, especially during filling, packaging, and transportation. Even a strong bottle can cause accidents if it slips easily on conveyor belts or during stacking. So, what does the slip resistance tester do?

- It measures the coefficient of friction between the bottle surface and contact surfaces.

- This reduces chances of bottles slipping, toppling, or causing line stoppages.

- Ensures bottles don’t slip easily from hands or storage racks.

- Helps bottles move smoothly on conveyors without jams.

Why Is Bottle Strength Testing Important?

Bottle strength testing helps manufacturers maintain consistent quality. Bottles experience high internal pressure from carbonated drinks, hot filling processes, and external stress during stacking and transport.

Without proper strength testing, bottles may leak, crack, or burst, leading to product loss, safety hazards, and brand damage. Regular bottle strength testing help minimize risks, reduces waste, builds customer trust, and most importantly, lowers cost.

Bottle Burst Tester: Common Questions & Answers

Q1: What Is a Bottle Pressure Tester?

Ans: A bottle pressure tester is another common term used for burst testing machines. It simulates real-life filling and carbonation pressure conditions to check whether a bottle can resist failure.

This test is especially critical for soda and sparkling beverage packaging, where pressure remains high even after sealing.

Especially, in the tropical climates, places with poor ventilation, and where bottles can face direct sunlight exposure, such as outdoors, open markets, or inside parked vehicles, pressure can be quite higher due to rapid heat up. These usually create expansion of plastic products, especially those with hollow interiors. To avoid these scenarios, a bottle pressure tester is a must.

Q2: How Does a PET Bottle Quality Test Ensure Safety?

Ans: A PET bottle quality test covers multiple aspects including burst strength, wall thickness, slip resistance, and top load. Among these, burst testing remains the most important, as it thoroughly checks the bottle can withstand carbonation and sealing pressure without breaking.

Q3: What Role Does Pressure Resistance Testing Play?

Ans: Pressure resistance testing identifies the maximum pressure a bottle can withstand without losing its shape or function. It makes sure that the bottles don’t burst during filling or storage, especially under extreme conditions like high carbonation or heat.

Pressure resistance testing also helps optimize production by identifying weak points that can be corrected early.

Q4: Why Is Burst Testing Equipment Essential?

Ans: Most of the modern machines, such as the Presto burst testing equipment, are automated, accurate, and user-friendly. It allows manufacturers to test bottles quickly and record precise results digitally. The price you pay for this machine will not only be one of your best investments but also help you to retain and increase your customer base. Alongside improving product safety, the burst testing equipment reduces wastage, complies with packaging regulations, and strengthens brand reputation.

Want to know the most reliable Bottle Burst Tester price for testing PET bottles and containers? At Presto Group, we offer high-quality, durable testers to ensure your packaging meets international standards.

Call us today at +91 9210 903 903 or email info@prestogroup.com to get an instant quote!

Recent Blogs

- Compression Testing Machine Operating Method & Packaging Strength Testing Applications

- Bottle Cap Torque Tester Digital Torque Testing for Packaging Quality Control

- Controlled Humidity Chamber: Environmental Testing Methods, Applications & Packaging Testing Use Cases

- Spectrophotometer & Portable Spectrophotometer: Working Principle and Laboratory Applications

- Paint Tester & Coating Testing Equipment: Types, Testing Process, and Industrial Applications