The cracking resistance of plastics could be affected due to several environmental stress, and is influenced by the different factors like the design of the container, treatments during and after production, molding conditions, and other related factors. Presto offers environmental stress cracking resistance to identify the effects of the different environmental factors on stress crack resistance of the container. This testing instrument is helpful for the plastic manufacturers to check the stress crack resistance. Plastic containers may crack due to the presence of certain substances like oil, detergent or wetting agents. Environmental stress cracking resistance helps in evaluating the effect of environment on polyethylene containers that are blow molded.

The cracking resistance of plastics could be affected due to several environmental stress, and is influenced by the different factors like the design of the container, treatments during and after production, molding conditions, and other related factors. Presto offers environmental stress cracking resistance to identify the effects of the different environmental factors on stress crack resistance of the container. This testing instrument is helpful for the plastic manufacturers to check the stress crack resistance. Plastic containers may crack due to the presence of certain substances like oil, detergent or wetting agents. Environmental stress cracking resistance helps in evaluating the effect of environment on polyethylene containers that are blow molded.

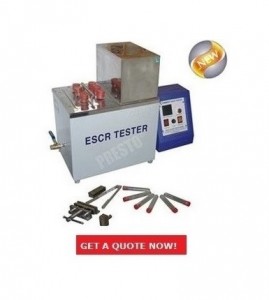

All the standard accessories are provided with the testing equipment such as digital temperature controller, cutting die, glass tubes, and foils. Presto cares for the safety of their testing devices, and therefore, the autumn gray and blue combination finishing and bright zinc or chrome plating is used to ensure resistance to corrosion.

A standard testing device to evaluate the effect of environment

The machine is operable on single phase 230 volts, 50 hertz with temperature range from ambient to 200 degree Celsius. The inner bath of the testing device is made of stainless steel, and outer body is made of mild steel duly power coated. The testing instrument is incorporated with are six number of stations.

The testing device is strictly designed as per ASTM D-1693 – 15 and is provided with the Calibration certificate traceable to NABL approved laboratories. The electric wiring diagram is also supplied by Presto. By testing the effect of stress and environment on the polymeric material, it improves the quality of plastic containers.