What is UV Coating?

UV or Ultraviolet Varnish, also called UV coating, is simply a liquid coating which is applied to a plain surface. It is then dried/cured with an ultraviolet light. A UV coating has the ability to make a printed area appear eye-catching.

Thus, UV coating is a very glossy, shiny liquid coating applied to a printed paper surface. Once cured on a printing press or special machine using ultraviolet light, the coating hardens, due to exposure to the ultra violet radiation.

UV coating can remarkably improve the aesthetics of a printed piece or box and so, it is perfect for products such as postcards, hand-outs, business cards and catalogs and attractive packages & boxes or any product that requires a rich and glossy appearance. A high-gloss flood UV coating can even be applied to synthetic paper.

After UV varnishing, the surface becomes thicker than uncoated area and seems glossy. Manufacturers often use UV coating on their packages in order to improve the aesthetic appeal of their package and ensure that their product logo stands out of the printing. In such cases, spot UV is a wonderful solution. It is often used for product branding, highlighting text and more. This step is inculcated in the process after offset printing and surface finish has been completed. The final finish could be glossy or matt.

For box packing, manufacturers and designers can use UV coating for cosmetic packaging of food boxes, display boxes and any another paper packaging.

Benefits of UV Coating

Ultraviolet coating offers several advantages over other coating methods such as aqueous coating or varnishing, such as:

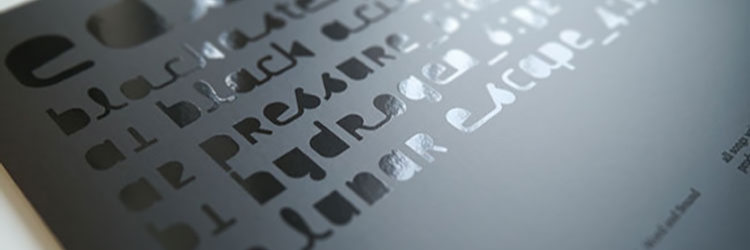

UV coatings provide a highly glossy finish to the surface and when it is applied on rich colors, such as deep blue and natural dark black, it imparts a very attractive, almost wet appearance, to the treated surface.

A combination of a high visually appeal and durability makes UV coating a preferred option for manufacturers. The UV coating allows the printed piece/box to resist smudging, endure wear & tear and yet maintain a professional, high quality appearance. This is made possible due to an extremely hard finish, one known for being both chemical and abrasion resistance.

UV coatings make details pop up and stand out. Thus, they are perfect for photographic images and company logos.

UV coatings are completely environment friendly, since the coatings are free of solvents. Unlike, varnishes, they don’t even emit volatile organic compounds, or VOCs when cured. In fact, paper with UV coatings can also be recycled with all of other kinds of paper.

UV coatingsdry very quickly. This helps reduce production time, enabling easy achievement of shipping and delivery deadlines.

Testing of UV Coating

The

Presto Scuff resistance Tester (Rub & Abrasion Tester) is a reliable tester for evaluation of UV Coatings. It offers consistent levels of repeatability and convenience. It is used for testing the durability of inks and coatings on any printed material.

The state-of-the art instrument is used for testing the scuff, marking and rub resistance of cartons, films and commercial printed material.

This is a comparative test and works by abrading a printed sample against a reference material under specified conditions. Besides helping manufactures to identify alternative substrates, the scuff resistance tester results can also be used to select better ink and coating formulations. Furthermore, these results can also be used to evaluate the suitability of finished cartons, films or printed books, magazines and promotional materials.

The Scuff resistance Tester can be programmed for a required number of cycles, enabling it to be run concurrently with other laboratory tests.

Moreover, if tests need to be conducted under harsher conditions, optional add-on attachments are easily available. These can be used to check not onlysolvent resistance, but also the cure of UV inks.

To know more information about its features, price, and technical specifications, give us a call/WhatsApp at

+91 9210903903 or email us at

info@prestogroup.com.