- /

- Blog / How Does a Corrosion Test Chamber Work? Complete Guide for Beginners

How Does a Corrosion Test Chamber Work? Complete Guide for Beginners

Corrosion is a natural but costly process that affects metals over time. Whether you're in the automotive, electronics, aerospace, or packaging industry, corrosion testing is important to ensure the durability and reliability of metal parts. That’s where a corrosion test chamber becomes very useful.

In this blog, we will explain how a corrosion test chamber works, what tests it performs, and why it's essential for manufacturers. This complete guide is great for beginners, also helpful for quality control professionals looking to know more about corrosion testing.

What Is a Corrosion Test Chamber?

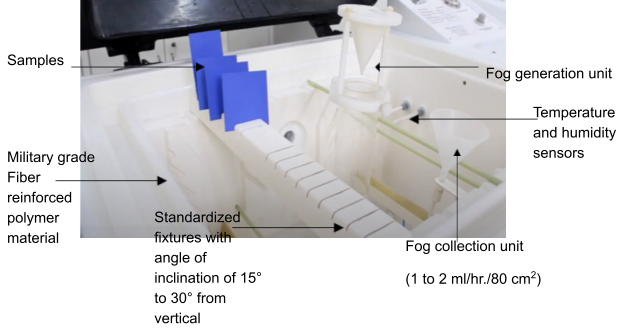

A corrosion test chamber (also called a salt spray chamber or salt fog chamber) is a laboratory device used to check how resistant a material is against corrosion under controlled environment. These chambers simulate harsh conditions like salt-filled air to speed up the corrosion process that usually takes months or years.

It is mostly used in industries for rust testing, especially for coated, painted, or plated materials.

How Does a Corrosion Test Chamber Work?

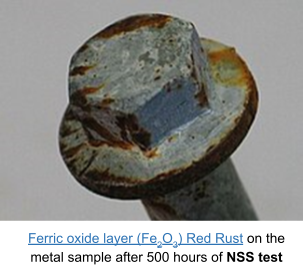

The most common method used in corrosion chambers is the Neutral Salt Spray Test (NSS), which is based on ASTM B117 standards. Here's how the process works:-

- Preparation of Salt Solution→

A 5% sodium chloride (NaCl) solution is made using distilled water. - Spraying Salt Fog→

The salt solution is atomized using compressed air and spread inside the chamber. - Chamber Conditions→

Temperature:→ Maintain at 35°C (±1°C)

pH Level:→ Between 6.5 and 7.2

Humidity:→ Nearly 100% - Placing Samples→

The materials being tested are placed on racks at an angle inside the chamber.

- Duration of Test→

Testing may run for 24, 48, 72, or even 96 hours depending on material and requirement. - Observation and Results→

After the test ends, samples are examined for rust, blistering, peeling, or any damage.

Common Tests Performed in a Corrosion Test Chamber

| Test Name | Description | Standard |

| Neutral Salt Spray Test (NSS) | Uses neutral pH salt solution to simulate marine corrosion | ASTM B117, ISO 9227 |

| Acetic Acid Salt Spray (AASS) | Includes acetic acid to increase corrosion rate for decorative coatings | ASTM G85, ISO 9227 |

| CASS Test | Adds copper chloride and acetic acid for testing nickel/chrome plating | ASTM B368 |

| Cyclic Corrosion Test (CCT) | Alternates between fog, drying and humidity for realistic aging simulation | ASTM D5894, ISO 16701 |

Applications of a Salt Spray Machine

A salt spray machine is used widely across industries like:

- Automotive: To test car parts, nuts and bolts.

- Paint & Coating: Verifies strength of protective coatings.

- Electronics: Tests durability of connectors and circuit boards.

- Aerospace: For checking aircraft component's resistance.

- Packaging: Used for moisture sensitive items and metal containers.

What Is ASTM B117 ?

ASTM B117 is the most known standard for performing the Neutral Salt Spray Test. It gives guidelines on how to test corrosion resistance of metallic and coated materials.

It is mainly used for:

- Checking quality of protective coatings

- Comparing performance of different materials

- Research & development purposes

Why Is Corrosion Testing Important?

Here’s why using a rust testing machine and corrosion resistance test is essential:

- Helps to predict product life in advance

- Avoids early failures in tough environments

- Reduces customer complaints and warranty claims

- Helps meet international testing standards

- Gives customer confidence in your product

Tips for Operating a Corrosion Test Chamber

- Always use pure salt and clean water to prepare the solution.

- Clean the nozzles to ensure uniform spray.

- Keep correct pH and temperature throughout the test.

- Calibrate the machine at regular time

Choosing the Right Corrosion Test Chamber for Your Needs

When selecting a corrosion test chamber:- it is important to consider your specific testing needs, industry standards, and the volume of testing you plan to do. Not every machine fits every application, so keep these factors in mind:-

Confused? Don’t worry… talk to our experts.

Key Factors to Consider:

- Test Type Required:

Do you need only Neutral Salt Spray Test (NSS), or do you also need Cyclic, AASS, or CASS testing? - Sample Size & Chamber Capacity:

Choose a chamber that can accommodate the size and quantity of your test samples. Overloading can affect results accuracy. - Compliance with Standards:

Ensure the chamber supports ASTM B117, ISO 9227, or other relevant standards for your industry. - Automation & Controls:

Look for chambers with digital controls, timers, auto pH monitoring, and water refilling for ease of use. - Durability & Build Material:

Chambers with corrosion--resistant internal components (like fiberglass or stainless steel) offer longer life and better performance. - After-Sales Support:

When purchasing a salt spray machine, it’s not only the equipment that matters. Good after-sales service is needed too. Ensure that the manufacturer provides adequate calibration, has spare parts in stock, and is accessible should you need technical assistance. This kind of support keeps your machine running well and saves you trouble in the long run.

A properly supported machine produces reproducible tests and streamlines your lab workflow and reduces maintenance costs over time.

FAQs

1. Why corrosion test is done?

To check how resistant a material is to rust, especially in harsh or marine-like environments.

2. What is salt spray test machine used for?

It is used for simulating corrosion and rust on materials to evaluate their resistance against salt-based environments.

3. How many hours is salt spray test?

Depends on product. It can be 24 hours, 48 hours, or more than 100 hours based on requirement.

4. Is salt fog chamber same as salt spray machine?

Yes, both are same instrument but different names are used in different industries.

To conclude

Knowing how a corrosion test chamber works is important if your product is exposed to moisture, salt, or industrial environments. Using a salt spray machine lets you test performance of coatings and metals in a shorter time under controlled condition.

No matter if it's neutral salt spray testing or a corrosion resistance test, the process ensures your materials stay reliable, safe, and ready for the market. Always follow ASTM B117 and proper testing protocols for the best results.

Confused? Don’t worry… talk to our experts.

Get the Best Corrosion Test Chamber Price Today!

Looking to invest in a reliable and accurate corrosion test chamber for your lab or production unit? Whether you need Neutral Salt Spray, CASS, or Cyclic Corrosion Testing, Presto Group has the perfect solution tailored to your needs.

- Get expert consultation

- Choose from industry-compliant models

- Get the best Corrosion Test Chamber price with full after-sales support

Call Now→ +91 9210 903 903

Email→ info@prestogroup.com

Act now and take the first step toward reliable, standard-compliant corrosion testing!

Recent Blogs

- Controlled Humidity Chamber: Environmental Testing Methods, Applications & Packaging Testing Use Cases

- Spectrophotometer & Portable Spectrophotometer: Working Principle and Laboratory Applications

- Paint Tester & Coating Testing Equipment: Types, Testing Process, and Industrial Applications

- Moisture Meter: Types, Working Principle & Applications in Industrial Labs

- Environmental,Pharmaceutical, and Research Laboratories in BOD Incubator