Glass bottles have been used in packaging for centuries, and they remain a popular choice for packaging a variety of products. From preserving the quality of products to enhancing the appeal of different products, these bottles will be the ideal choice for glass bottles. Thus, we at Presto have designed one of the high-quality laboratory testing instruments known as an impact tester for glass bottles. This is one of the high-quality lab testing equipment that is used in the glass bottle industry to test the impact resistance of glass bottles and ensures that quality materials will be delivered to the customers.

This is one of the high-quality laboratory testing equipment that will test different characteristics of the products to ensure that these materials will be able to withstand the impact resistance of the materials. In this blog, we will discuss a brief Presto impact resistance tester for glass bottles and how this quality lab testing instrument is useful in ensuring that the bottle can withstand the rigors of transportation without breaking or damaging the contents inside. So, let us get started!

Why glass bottles should be tested for impact resistance?

Testing the impact resistance of glass bottles is crucial to ensure their safety, quality, and reliability. Glass bottles are widely used for storing beverages, medicines, and chemicals, and they can shatter upon impact, causing injuries and product loss.

By testing the impact resistance of glass bottles, manufacturers can identify potential weaknesses in their products and take corrective action to avoid costly breakages. Moreover, testing helps to ensure that glass bottles can withstand the rigors of transportation without breaking or damaging the contents inside and that only high-quality products are released to the market.

Overall,

testing the impact resistance of glass bottles is an essential step in the manufacturing process to ensure the safety, quality, and satisfaction of consumers. You can read more on how the

internal strain of glass can be tested and make bottles free of any product errors.

Now, let us discuss a brief about Presto impact resistance tester for glass bottles.

Ensure your Glass Bottles are safe and durable with Presto's Impact Tester for Glass Bottles

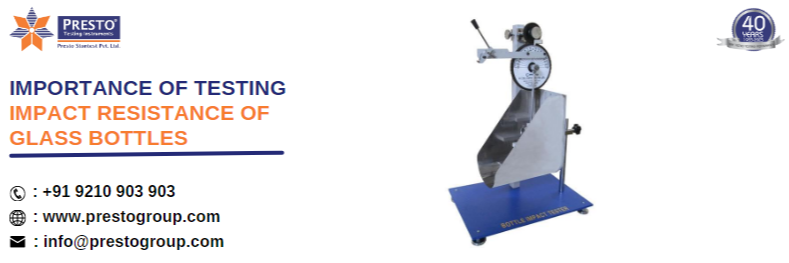

Presto's Impact Tester for Glass Bottles is a testing instrument designed to determine the impact resistance and breakage of glass bottles and containers. The tester applies a reproducible strength to evaluate the ability of the glass bottle to withstand impact and determine its strength-related characteristics.

This laboratory testing instrument provides a reliable and accurate method to assess the safety and durability of glass bottles and containers for various applications, including packaging for food, beverages, and pharmaceuticals.

The

Impact Tester for Glass Bottles from Presto is a crucial testing instrument for manufacturers to ensure that their products meet safety standards and are of high quality, providing peace of mind to consumers. You can easily

remove stress from glass products to have flawless glass pieces.

Now, let us discuss a brief about its features and technical specifications.

Features of Presto Impact Tester for Glass Bottles

By subjecting glass bottles to various impacts under controlled conditions, manufacturers can determine the strength-related characteristics of the bottles and ensure that they meet safety and quality standards. There are different features of this quality testing instrument that are listed below.

- A lightweight instrument with a rigid suspension that holds an everlastingly associated pendulum assembly.

- The head of the impact tester is designed to enhance the impact load applied to the container.

- The Crank & Screw of the instrument offers rapid, reproducible, and accurate height adjustments.

- An optional anvil spacer of a small diameter is provided with the machine.

- Standard: DIN 52295-2010

Technical Specifications:

- Indenter: Anti-friction needle bearing with correct alignment and minimum inertia.

- Force: lbs/inch

- Backstop: Steel backstop along with changeable positioning guide.

- Impact level is adjustable over a range of 0 to 22 inch-pounds available energy

- Angle: 0 to 120 Degrees

- Maximum Impact Energy: 2.35 Nw/m

- Impact Weights: 2 weights - 2.6Nw/m, 2.35Nw/m

- Height: Adjustable height for the bottle

To know about

impact resistance tester price or other related information, give us a call at

+91 9210903903 or email us at

info@prestogroup.com. Our team of technical experts will consult you regarding all your needs and queries.