In the world of plastic and polymer, flow behavior is one of the most important parameters that determines the quality and process of the material. The manufacturer, the R&D team and quality managers rely on the Melt Flow Index (MFI) test to assess this property correctly. To perform this test, the industries use a melted flow -examiner (MFI examiner), to ensure an essential tool, which meets the necessary standards for polymer extruding, casting and other production processes.

This article suggests what is the flow index test, the role of an MFI sensor, test standards, devices, formulas, applications and benefits to understanding its full significance in polymer quality control.

The melt flow index test measures the ease of flow of a thermoplastic polymer when melted. It is defined as the mass of polymer, in grams, that flows in 10 minutes through a capillary die under a specified load and temperature.

It gives an indication of the flow rate of the polymer.

Higher MFI → lower viscosity → easier flow.

Lower MFI → higher viscosity → harder flow.

Why it matters:

Process engineers use MFI to select suitable polymers for applications like injection molding, extrusion, and blow molding.

Manufacturers use MFI to maintain consistency in production.

Customers use MFI data to compare different grades of polymers.

A melt flow index tester (also called MFI tester) is a laboratory testing instrument designed to perform the MFI test in controlled conditions.

Key Components:

Heated barrel – Maintains precise temperature for the polymer.

Piston & weights – Applies a constant force on the melted sample.

Capillary die – Narrow opening through which polymer flows.

Cutter or timer – Measures the extrudate over a given time.

The melt flow index diagram usually shows how a polymer sample is heated, pressed through the die, and weighed to calculate the melt flow rate.

By using an MFI tester, industries can replicate ASTM D1238 or ISO 1133 test conditions and get consistent results across batches.

Unit: The melt flow index is measured in grams per 10 minutes (g/10 min).

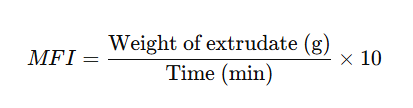

Formula:

MFI = (Weight of extrudate in grams ÷ Time in minutes) × 10

Example Calculation:

Example Calculation:

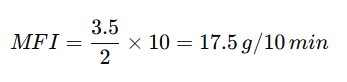

If 3.5 g of molten polymer flows through the die in 2 minutes under a given load and temperature:-

MFI = (3.5 ÷ 2) × 10 = 17.5 g/10 min

This means the polymer has a high flow property, making it suitable for injection molding applications.

This means the polymer has a high flow property, making it suitable for injection molding applications.

Testing must follow international standards to ensure repeatability:-

Both standards specify the temperature, load conditions, and equipment requirements for conducting the MFI test.

MFI testers are widely used across industries that depend on plastics and polymers.

Polymer Manufacturing

Plastic Processing

Quality Control & R&D

End-Use Applications

When selecting an MFI tester, consider the following:

Manual vs. Digital:

Temperature Control:

Load Range:

User-Friendly Interface:

Compliance with Standards:

Q1. What is a melt flow index tester used for?

A melt flow index tester is used to measure the flow rate of molten thermoplastic polymers under controlled conditions.

Q2. What is the unit of melt flow index?

The standard unit is grams per 10 minutes (g/10 min).

Q3. How do you calculate melt flow index?

By dividing the weight of polymer extrudate by the elapsed time and multiplying by 10.

Q4. Which polymers are tested using MFI testers?

Commonly tested polymers include PE, PP, PS, ABS, PVC, PET, and nylon.

Q5. What standards are followed for MFI testing?

The two most widely accepted standards are ASTM D1238 and ISO 1133.

Presto Group is a trusted provider of high-precision Melt Flow Index Testers (MFI testers), designed to deliver accurate and consistent polymer testing in compliance with ASTM D1238 and ISO 1133 standards. While offering both manual and digital models, the candidates meet the needs of diverse industry. Presto Group equipment is created for reliability and long -term durability, and ensures spontaneous operations in laboratories and production environment. Experts help to maximize testing efficiency, with post -installation, calibration and post -sales support. Choose Presto Group for a dependable, accurate, and robust MFI tester tailored to your polymer quality control requirements.

The melt flow index tester is an indispensable tool for manufacturers, researchers and quality leaders in the polymer industry. By measuring the polymer current accurately, it ensures better processing, high quality products and cost efficiency.

Whether you are in R&D, quality control or large -scale production, which invests in a reliable MFI sensor guarantees continuity and compliance with international standards.

Ensure precise measurement of polymer flow properties with Presto Group’s Melt Flow Index Tester. Designed for accuracy and ease of use, our testers help manufacturers, R&D labs, and quality control teams evaluate polymer consistency and processability effectively.

Why Choose Our Melt Flow Index Tester?

Accurate and repeatable measurements for all types of polymers

Easy-to-use interface for efficient lab operations

Durable build with low maintenance requirements

Competitive pricing tailored to your budget

Call us now at +91 9210 903 903

Email: info@prestogroup.com

Get a quote for Melt Flow Index Tester Price today and take control of your polymer testing process!