Viscosity is a key constraint when any flow measurements of fluids such as semi-solids, gases, liquids, are made. Viscosity measurement is done by combining the product quality and efficiency. If anyone involved measuring the flow properties of the melted plastics, it is necessary to take all necessary steps for effective research and quality inspection to measure the viscosity of the products.

Why measuring the viscosity of polymers is essential?

The information on the performance of the material’s viscosity offers the relevant information to the manufacturers regarding the material dimension, strength and required specifications of the product. This helps the manufacturers to understand that rheological features are valuable in predicting the pouring ability, performance in coating operation, or the ease with which it is handled, processed and used. The relationship between the rheological properties and dimension helps the manufacturers to measure the sensitivity, viscosity and helps to detect various other properties such as solid contents, color, density, molecular weight, the stability of the polymers, etc. Presto Stantest deals in manufacturing and designing a different testing machine to measure the properties of different polymers.

Viscosity – Best to Determine Viscosity

The relationship of the polymers helps the manufacturers to deeply analyze and understand the flow of the materials on which the manufacturers is working so that the behavior of the materials at the time of molding can be analyzed easily and efficiently.

There are numerous testing methods that measure the viscosity of the polymers. To meet the high-quality production requirements, the material needs to be suitable enough as per the production requirements and circumstances. The selection of the testing device from the available testing devices to meet the demand for any application is a difficult proposal.

Range of Testing Instruments for Viscosity Measurement

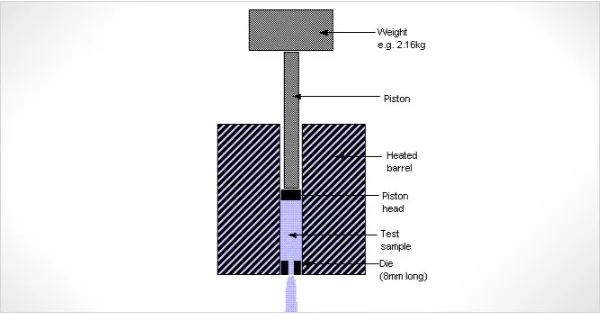

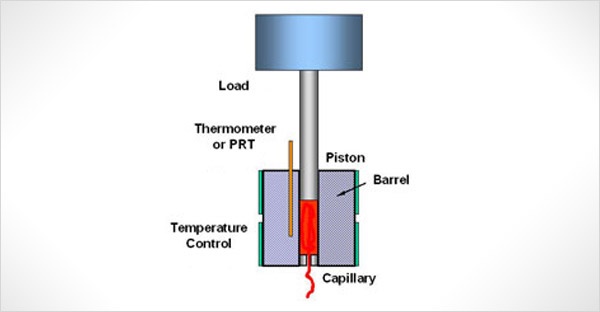

Nowadays, the viscosity measurement of plastics can be done in numerous forms i.e. simple to complex that efficiently count every second of melted plastics when it flows out with the sophisticated controlling device and automatic reading. To perform the test efficiently the testing machine is first placed in the position and operated by following a highly standardized procedure as stated in the standards to calculate the properties of plastics accurately such as melt volume rate, melt flow rate, viscosity rate, etc.

Many manufacturers considered Melt Flow Index Testers for viscosity measurements as the best testing device to determine the quality of the plastics for research and development purposes and for controlling the program process. They understand that the viscosity measurement is the quickest, reliable and accurate mode to analyze the critical essentials that affect the performance of the product. Apart from measuring the properties, determining the viscosity of the plastics helps the manufacturers to understand the physical & chemical properties of the plastics especially when they are treated at different temperatures during production to produce a high-quality product. These properties help the manufacturers to measure the molding strength of the polymers when it is required to provide a particular shape to it via melting.

Melt Flow Index of Polypropylene

Polypropylene is a highly preferred raw material which is used by the packaging industries. These materials are flexible in nature and have the moderate strength that could be molded into different shapes. The material is preferred due to numerous features such as high-temperature resistance, good impact strength, chemical resistance to oils, excellence moisture resistance, low COF, etc.

Polypropylene is widely used for various applications such as upholstery, battery cases, CD packaging, non-woven production, paint boxes, water system pipes, pipe fittings, storage boxes, transparent kitchen articles, and many more. The quality of the polypropylene has a significant role for all these applications. Therefore, it is mandatory to measure the ease of flow of melted polypropylene. The MFI is a commonly used testing device to measure the flow of melted plastics to measure the strength of the materials.

Key Expertise of Melt Flow Index

Apart from testing the MFI Tester of polypropylene, the testing machine is used to test other types of plastics as well such as polyethene, polymer, thermoplastic, etc. The test is helpful to measure the impact strength and viscosity of the molten plastics. The testing instrument has microprocessor based PID temperature controller. The temperature range of the device can be set easily between ambient to 400 degree Celsius to melt the plastics easily.

Presto Stantest offers testing machines to measure the properties of the polymers such as MFI tester. The testing instrument is designed by the skilled professionals keeping in mind the standards that are introduced by various standardization authorities. The Presto’s MFI tester complies with various standards such as IS 2530-1963 (R2003), IS 10810-1984, ASTM D1238-13. This device ensures that the device offers highly precise and accurate test results.

For more information on MFI tester, contact Presto.

Related Blogs

Hot Air Oven uses dry heat for sterilizing glassware and metal tools, while an Autoclave uses steam under pressure—ideal for liquids and medical items.

GSM of fabric (Grams per Square Meter) indicates fabric weight and thickness. Higher GSM means denser, heavier fabric; lower GSM means lighter, thinner fabric.

Discover why abrasion resistance is crucial for packaging, textiles & plastics. Learn how it's tested (Martindale, Taber, DIN) & why it boosts durability. Save costs with wear-resistant materials!