Cupping testing machine is widely used in sheet metal industries for determining the ductility of the metal sheets. This test helps you analyze the level of deformation on sheets when they are subjected to an amount of pushing force. Let us discuss on how to make use of cupping test for better quality of sheet metal products.

It is also used to analyze the quality of paint which are applied to the metallic substrates for protecting the latter from environmental damage. With the help of this test, the paint manufacturers can easily evaluate the elastic properties of the paint and study the development of cracks in the surface coating once they are stretched with the substrate on applying force.

If you have any queries regarding the cupping test machine, kindly contact our experts

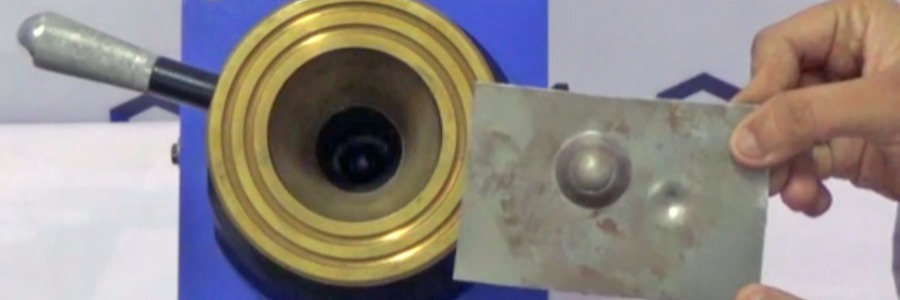

A cup is formed on a sheet by pressing a spherical punch against the clamped specimen until there is a visible crack developed on the sheet. After the crack develops, the force application is stopped, and the depth of the cup is measured as the test results.

• The machine should have a die and a blank holder installed in it.

• The machine should allow the tester to view the test procedure from outside.

• The crack that is developed in the specimen during the test should be wide enough to allow the light to pass.

Additionally, it should be all over the width of the specimen.

• Proper gauges should be installed on the machine for accurate measurement.

• The punch is not allowed to turn when the test is being conducted.

• The punch should have a hemispherical and polished working surface.

• A constant load force of 10 KN should be applied to the test piece.

• The measurement of the movement of the punch will be done from the point where it touches the surface in the initial stage.

• High-quality rugged structure with corrosion resistant main body

• Sturdy and resilient construction

• Revolving handle for frictionless movement of punch

• Faster guiding mechanism with hand operated wheel

• Single-handed hassle-free operation with spherical punch

• Brass housing for strong sample clamping

Know which other features can improve the cupping test results.

This is how you can make good use of cupping test for better quality of sheet metal products.

It is just a matter of few minutes, which you can invest today for getting the right testing instrument for your company rather than suffering a huge loss tomorrow.

Related Blogs

Hot Air Oven uses dry heat for sterilizing glassware and metal tools, while an Autoclave uses steam under pressure—ideal for liquids and medical items.

GSM of fabric (Grams per Square Meter) indicates fabric weight and thickness. Higher GSM means denser, heavier fabric; lower GSM means lighter, thinner fabric.

Discover why abrasion resistance is crucial for packaging, textiles & plastics. Learn how it's tested (Martindale, Taber, DIN) & why it boosts durability. Save costs with wear-resistant materials!