- /

- Blog / What is an Autoclave? Working Principle, Types, and Applications Explained

What is an Autoclave? Working Principle, Types, and Applications Explained

An autoclave is a heavy-duty machine that wipes out germs—bacteria, viruses, and even those stubborn spores—using scorching hot steam and pressure. Picture a souped-up pressure cooker designed to make sure things like surgical tools, lab equipment, or tattoo needles are totally clean and safe. You’ll find these machines in hospitals, microbiology labs, dental offices, and even tattoo shops. In this blog, I’m gonna walk you through what an autoclave is, how it gets the job done, the different kinds out there, where they’re used, what they cost, and answer some questions people often ask—all in plain, no-nonsense talk.

What is an Autoclave?

Think of an autoclave as a germ-killing beast. It uses steam, heat, and pressure to make sure medical tools, lab gear, or anything else is free of bacteria, viruses, or anything that could cause trouble. The word “autoclave” comes from Greek, meaning “self-locking,” because it seals up tight to keep the steam inside. It’s a must in places like hospitals or labs where even one germ could lead to infections or ruin experiments.

How Does an Autoclave Work? The Simple Version

An autoclave kills germs by hitting them with hot steam under high pressure. Steam works better than dry heat, like from an oven, because it gets into every tiny corner. Here’s the deal:

- Making Steam: There’s a water tank inside the autoclave. It heats the water until it turns into steam, and that steam gets crazy hot—way hotter than boiling water, like 121°C to 134°C (250°F to 273°F).

- Pressure and Heat: The machine locks the steam in a sealed chamber, cranking up the pressure. This makes the steam even hotter, which wipes out all germs, even the really tough ones like bacterial spores.

- Timing: The stuff inside gets steamed for about 15–30 minutes, depending on what you’re cleaning. This makes sure every germ is toast.

- Cooling Off: When it’s done, the autoclave lets out the steam, drops the pressure, and cools down. Some models even dry the items so they’re ready to go.

This combo of heat, pressure, and steam makes sure nothing nasty survives. The machine keeps everything under control, so it’s super reliable.

Main Parts of an Autoclave

Here’s what makes an autoclave tick:

- Chamber: The sealed box where you put the stuff to clean.

- Heater: Boils the water to make steam.

- Controls: A panel where you set the temperature, pressure, and time.

- Safety Valve: Stops the pressure from getting too wild.

- Drain: Gets rid of extra water or steam when you’re done.

Types of Autoclaves

Autoclaves come in different styles for different jobs. Here’s the rundown:

1. Gravity Autoclaves

These are the basic ones. Steam goes in, pushes the air out through a valve, and cleans the items. They’re perfect for solid stuff like metal tools, glassware, or surgical gear.

2. Vacuum Autoclaves

These use a pump to suck out air before adding steam. This lets the steam get into tricky spots, like inside wrapped tools or fabrics. They’re quicker and great for complicated stuff.

3. Steam-Flush Autoclaves

These blast steam in and out in bursts to clear out air. They’re a middle ground between gravity and vacuum models and work for lots of different items. Hospitals love them.

4. Benchtop Autoclaves

These are small, portable ones for places like dental offices or tiny labs. They’re easy to use and good for cleaning a few tools at a time.

5. Vertical and Horizontal Autoclaves

- Vertical: You load these from the top. Labs use them for things like petri dishes or media.

- Horizontal: These are bigger, front-loading, and used in hospitals or factories for big batches.

Pick the one that fits what you’re cleaning and how much you need to do.

Autoclave Types and Uses: Quick Summary Table

Here’s a table to show what each autoclave type is best for:

| Autoclave Type | Best For | Common Uses |

| Gravity Displacement | Solid stuff like tools, glassware | Labs, clinics, basic cleaning |

| Vacuum (Pre-Vacuum) | Wrapped or porous items | Hospitals, complex medical gear |

| Steam-Flush Pressure-Pulse | Mixed loads, all-purpose cleaning | Hospitals, big clinics |

| Benchtop | Small batches, portable use | Dental offices, small labs |

| Vertical/Horizontal | Labs (vertical), big loads (horizontal) | Labs, hospitals, factories |

Where Are Autoclaves Used?

Autoclaves pop up in all sorts of places. Here’s where you’ll find them:-

1. Autoclaves in Microbiology: Microbiology labs need everything super clean so experiments don’t get messed up by random germs. Autoclaves clean petri dishes, pipettes, and media. They also safely get rid of biohazardous waste, like used samples.

2. Hospitals and Clinics: Hospitals use autoclaves to clean surgical tools, bandages, and anything that touches a patient to avoid infections. Dental offices use them for stuff like drills or mirrors to keep things safe.

3. Pharmaceuticals: Drug companies use autoclaves to clean equipment and materials so medicines are pure. This is huge for meeting health rules.

4. Industrial Uses: Some industries, like aerospace, use autoclaves to heat and toughen materials like carbon fiber for airplane parts. Here, it’s less about germs and more about making things strong.

5. Tattoo and Beauty Shops: Tattoo artists and salons use autoclaves to clean needles, piercing tools, and other gear to keep clients safe from infections.

6. Research and Schools: Universities and research labs use autoclaves to clean experiment gear. Veterinary clinics use them for tools to treat animals.

How to Use an Autoclave Right

Using an autoclave isn’t rocket science, but you gotta do it properly. Here’s the deal:

- Don’t Overload: Leave space so steam can get everywhere.

- Use the Right Stuff: Put items in heat-safe trays or autoclave bags.

- Check Settings: Set the right temperature, pressure, and time for what you’re cleaning.

- Keep It Clean: Wipe down the machine regularly and check for problems.

- Stay Safe: Wear gloves, don’t open it when it’s hot, and follow the rules.

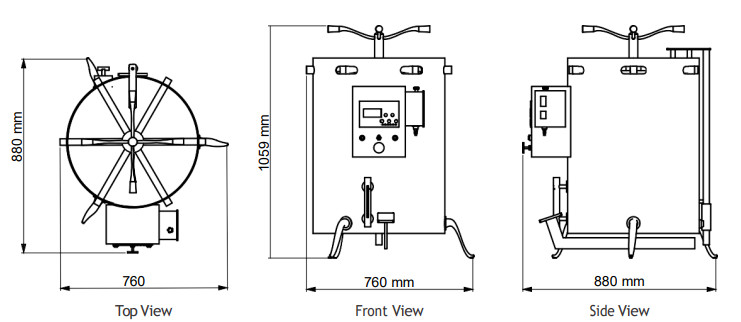

Autoclave Diagram: What It Looks Like

Think of an autoclave as a big metal box or cylinder with a locked door. Inside, you’ve got:

- A chamber for the stuff you’re cleaning.

- A water tank for making steam.

- A heater to boil the water.

- A control panel to set things up.

- A safety valve to keep pressure in check.

- A drain for leftover water or steam.

It’s a simple setup, but every part’s gotta work together to get the job done.

Frequently Asked Questions About Autoclaves (FAQs)

Here’s what people often ask about autoclaves:

Q1. How long does it take to sterilize stuff?

Ans: Usually 15–30 minutes for the actual steaming, depending on what’s inside. Vacuum autoclaves are faster for tricky items. Add time for heating up and cooling down, so the whole thing might take 30–60 minutes.

Q2. Can you put anything in an autoclave?

Ans: Nope. It’s great for metal tools, glassware, and some fabrics, but stuff like certain plastics or electronics can melt or break. Check if your items can handle the heat and steam.

Q3. Why do microbiology labs need autoclaves?

Ans: Labs need everything germ-free so experiments aren’t ruined by stray bacteria. Autoclaves clean dishes, media, and tools. They also make biohazardous waste safe to toss out.

Q4. How often do you need to service an autoclave?

Ans: Clean it weekly to keep it in shape. For big checkups, like looking at valves or seals, once or twice a year by a pro should do it, depending on how much you use it.

Why Use an Autoclave?

Here’s why autoclaves rock:

- They Get the Job Done: They kill even the toughest germs.

- They’re Versatile: They clean all sorts of stuff, from tools to liquids.

- They’re Dependable: Use them right, and they work every time.

- They’re Eco-Friendly: Just steam and water, no nasty chemicals.

Downsides of Autoclaves

They’ve got some drawbacks:

- Pricey: Big ones cost a ton.

- Not for Everything: Heat-sensitive stuff like some plastics can’t go in.

- Learning Curve: You gotta know how to use them.

- Upkeep: They need regular care to keep running.

Why Choose Presto Stantest Pvt. Ltd. Autoclave?

- High Quality: ISO 9001:2008 certified, awarded First Prize National Award for Quality Manufacturing (2017), meeting ASTM and ISO standards.

- Advanced Features: Hysteresis, purging, proportional band settings, auto cut-off, stainless steel baskets, and water level indicators for safe, efficient sterilization.

- Fast Sterilization: Achieves sterilization in ~15 minutes at 15 psi, ideal for busy labs and medical facilities.

- Trusted by Leaders: Used by Akzo Nobel, Honda, Amazon, and others for accuracy and reliability.

- Excellent Support: Prompt delivery, installation, training, and ongoing technical support with regular site visits.

- Global Expertise: Exports to 47+ countries, serving medical, veterinary, and industrial sectors with 40+ years of experience.

- Safe & Customizable: Corrosion-resistant stainless steel, various chamber sizes, and safety features like auto cut-off.

- Customer-Centric: Positive reviews for tailored solutions, quick response, and reliable service.

Wrapping It Up

Autoclaves are straight-up lifesavers in places like hospitals, labs, or tattoo shops. They blast germs with steam and pressure, making sure stuff like surgical tools, lab dishes, or piercing needles is clean and safe to use. No matter what you’re sterilizing, there’s an autoclave out there that’ll do the trick. They cost a pretty penny, but when it comes to keeping people safe or experiments legit, they’re worth every cent. If you’re thinking about getting one, pick the right type and size for your needs, and don’t skimp on taking care of it. It’s a machine that gets the job done right, every time.

Looking for the Best Autoclave Price?

Get expert guidance and the most competitive Autoclave price tailored to your needs. Whether you need a compact model or a large industrial unit, we’ve got you covered!

Call Now:- +91 9210 903 903

Email Us:- info@prestogroup.com

Reach out today and get your personalized quote!

Recent Blogs

- Controlled Humidity Chamber: Environmental Testing Methods, Applications & Packaging Testing Use Cases

- Spectrophotometer & Portable Spectrophotometer: Working Principle and Laboratory Applications

- Paint Tester & Coating Testing Equipment: Types, Testing Process, and Industrial Applications

- Moisture Meter: Types, Working Principle & Applications in Industrial Labs

- Environmental,Pharmaceutical, and Research Laboratories in BOD Incubator