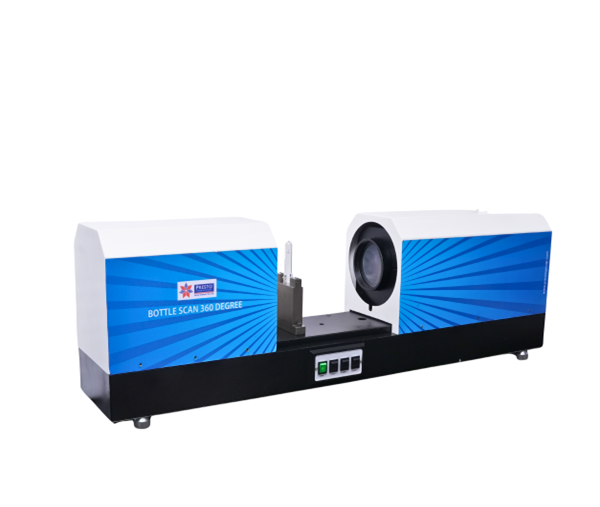

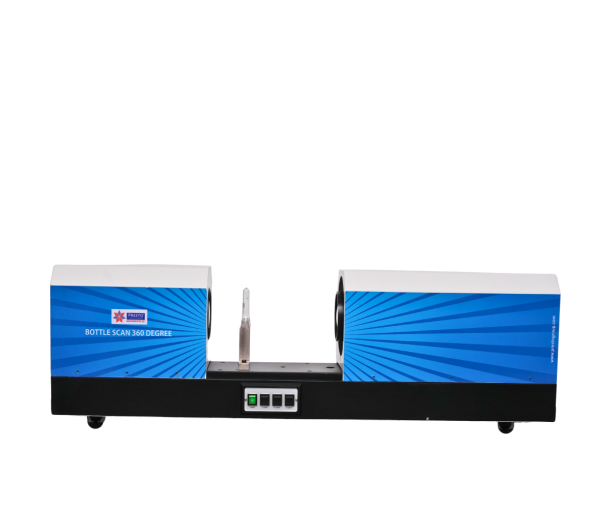

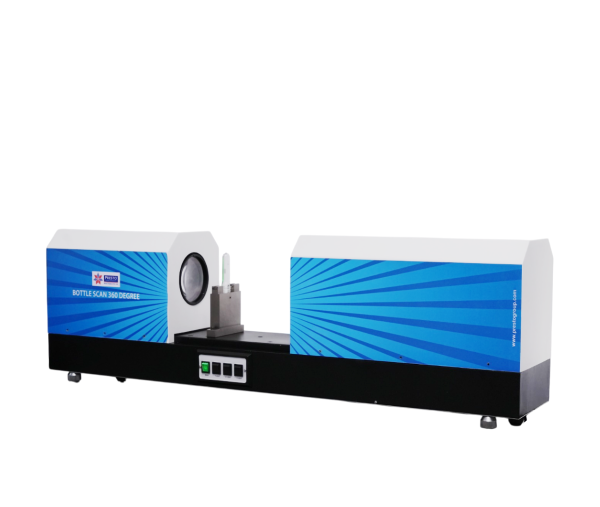

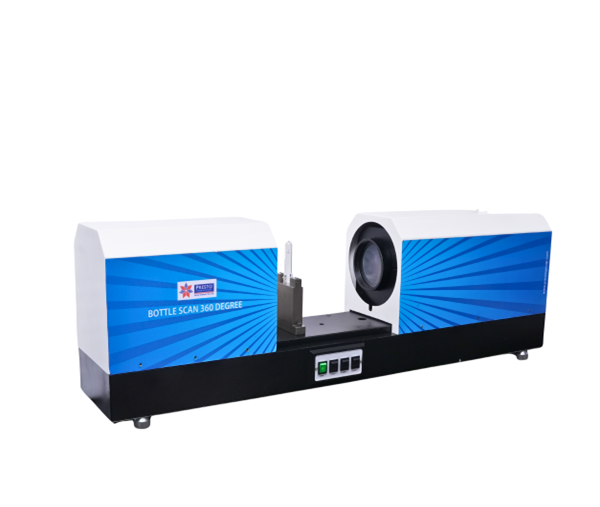

Brief insight into Bottle Scan 360 for Vision Measurement System

Bottle Scan 360 watches the full body of a bottle as it rotates. Cameras capture the shape from all sides. The unit shows live images and highlights any irregular areas. This helps the plants to carry out routine checks on PET, HDPE, glass, and similar containers with ease. The tool supports fast decisions during production.

Applications for Vision Measurement System

• It helps beverage units to check the bottle shape before filling.

• It helps pharma plants to watch wall consistency and neck form.

• It helps cosmetic brands to catch small dents and lean in high-speed lines.

• It helps the household and chemical units to study bottle roundness and symmetry.

• It helps to mold the shops and check samples before bulk runs.

• It helps QC teams to compare batches and spot design shifts.

Standard compliance

The unit follows common visual and dimensional check practices used in bottle inspection labs. The viewing angle and rotation stay aligned with accepted procedures followed during roundness, lean, and surface review of containers.