Vision measurement instruments are precision tools used to inspect and measure the physical dimensions of objects using optical systems, often without direct contact. These instruments are essential in quality control, manufacturing, and engineering, as they ensure components meet strict specifications and tolerances. It measures any kind of 2D geometry in parts with just one click. This ONE CLICK MEASUREMENT SYSTEM is cable of measuring points, lines, circles, angles, distances, pitch, positions, etc.

|

1. |

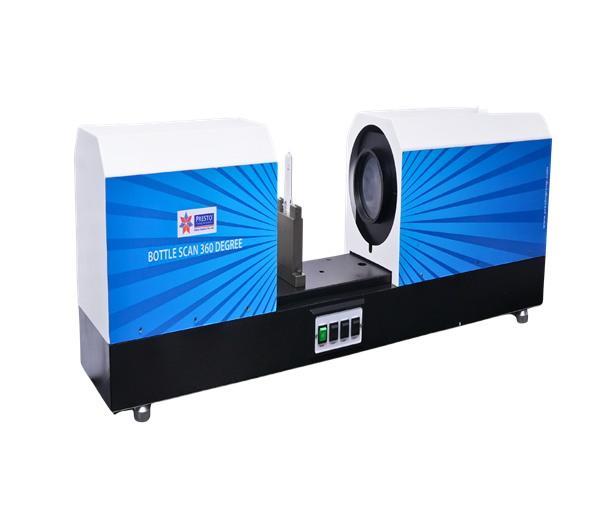

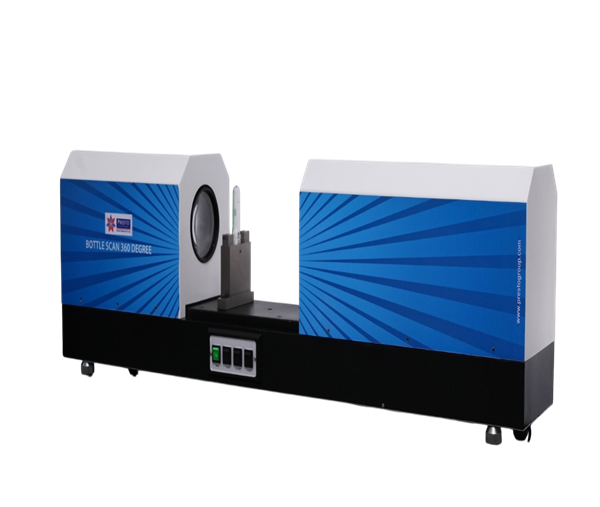

Field of View ( Round) |

ø 120 mm |

|

2. |

Depth of Field |

45 mm |

|

3. |

Field of View ( Rectangle) |

95*70 mm |

|

4. |

No. of Camera |

1 No. |

|

5. |

Camera |

20 MP Industrial Camera |

|

6. |

Accuracy |

±3+L/30µm |

|

7. |

Repeatability |

±3µm |

|

8. |

Least Count |

1 µm |

|

9. |

Power Supply |

220 ± 10 VAC @50 Hz |

|

10. |

View |

Side View |

|

11. |

Lens Type |

Concave 5x70 |

|

12. |

Interface |

USB/Ethernet |

|

13. |

Hardware |

Compatible with win 7/10/11 + |

|

14. |

Measurement point |

10000 |

|

15. |

Batch Programming |

Yes |

Advanced Features of Vision Measurement & Optical Inspection System:

· Automated Optical Inspection (AOI): Delivers high-speed, high-accuracy visual inspection powered by precision imaging and intelligent software, ideal for detecting defects and dimensional deviations.

· Simultaneous Multi-Part Inspection: Capable of inspecting multiple components in a single cycle, significantly enhancing throughput and reducing inspection time per unit.

· Tele-centric Lens System: Ensures distortion-free imaging with constant magnification, providing superior edge accuracy and repeatable measurement results across varied object heights.

· Ultra-Fast Inspection Cycle: Executes full inspections within seconds, optimizing production efficiency without compromising measurement precision.

· Automated Report Generation: Generates detailed Excel reports with real-time pass/fail data, enabling traceable quality control and streamlined documentation.

· Integrated Machine Control Interface: Offers intuitive controls for initiating, pausing, and halting operations, including a built-in emergency stop for enhanced operator safety.

· Secure Data Acquisition and Storage: Automatically logs inspection data directly from the system software, ensuring data integrity and secure archival for audit compliance.

· Real-Time Machine Monitoring: Tracks system health, operational uptime, and performance metrics to enable predictive maintenance and minimize unexpected downtimes.

· Guided Operational Support: Provides interactive step-by-step instructions and standardized operating procedures (SOPs) to assist operators in executing critical tasks accurately and efficiently.

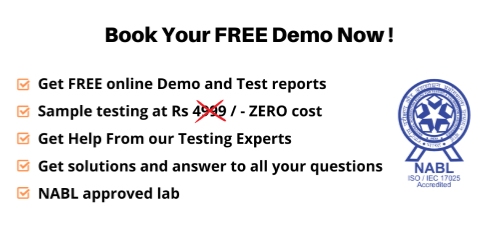

Trusting by the best, serving the best