- /

- Article / Charpy Impact Test: Meaning, Method, Applications & ASTM Standards

Charpy Impact Test: Meaning, Method, Applications & ASTM Standards

The Charpy Impact Test is a basic but powerful technique used all over the world to measure how tough different materials are. In industries where structural strength really matters—like in cars, planes, and buildings—-this test is super important. It was developed back in 1905 by Georges Charpy, and it's still being used today because it's simple and it works.

In this guide, we'll explain how the test works, why it matters, and what it tells us. We’ll also compare it with the Izod test and share where it’s most useful.

A Quick History of the Charpy Impact Test

The Charpy test was first introduced by Georges Charpy, a French scientist, in 1905. It was designed to quickly show how tough a material is when hit suddenly. Even after more than 100 years, it’s still one of the most trusted ways to check material toughness.

What is the Charpy Impact Test?

The Charpy Impact Test checks how much energy a material can absorb when it breaks from a sudden blow. This tells us whether a material will crack or bend when hit.

A small, notched sample is hit by a pendulum hammer, and the energy used to break it is recorded. It’s really helpful for checking how materials react in cold weather, when they often become more brittle.

How Does a Charpy Impact Tester Work?

A Charpy impact tester uses a swinging pendulum that hits a notched bar of material supported at both ends. The energy absorbed by the specimen during fracture is recorded—typically in joules.

The test setup consists of:

- A pendulum of known mass and length

- V-notch specimen

- Anvil supports

- Digital/Analog energy display

After the impact, the height to which the pendulum swings is reduced. The difference in height before and after the impact allows the calculation of absorbed energy using the conservation of energy principle.

.jpg)

Charpy Impact Test Procedure- Step-by-Step

- Specimen Preparation

Standard size- 127 mm × 12.7 mm (lower limiting value of thickness 3 mm)

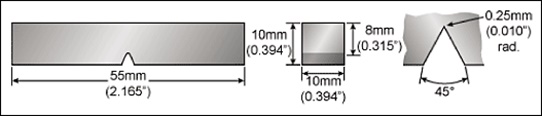

A V-notch (2.54 mm deep, 45° angle) is machined to create a stress concentration. - Specimen Mounting

The sample is placed horizontally on the machine with the notch facing away from the pendulum. - Pendulum Release

The pendulum is dropped from a calibrated height and strikes the specimen at the center. - Energy Measurement

The energy absorbed to fracture the material is recorded automatically.

.jpg)

Advanced models also allow temperature-controlled testing to evaluate material behavior under different environmental conditions.

Charpy impact test formula

Energy is calculated like this:

E = m × g × (h1 - h2)

Where:

- E = Energy absorbed (joules)

- m = Mass of the pendulum

- g = Gravity (9.81 m/s2)

- h1 = Starting height

- h2 = Height after impact

It’s a simple formula, but it gives good results if the machine is calibrated right.

.jpg)

Charpy Results: Low vs High Strength Materials

Results can look really different depending on what kind of material you test:

- Low strength stuff (like plastics or mild steel) absorbs more energy and usually bends before breaking.

- High strength stuff (like hardened steel) absorbs less energy and tends to crack suddenly.

This helps companies pick the right material depending on where and how it will be used.

Destructive vs Non-Destructive Testing: What Kind is Charpy?

Charpy is a destructive test. That means the sample breaks and can’t be used again.

Destructive Tests:

- Break the material

- Examples: Charpy, tensile, and hardness tests

Non-Destructive Tests:

- Leave the material unharmed

- Examples: Ultrasonic, X-ray, and magnetic tests

Destructive tests are great during product development or when picking materials. NDT is better for finished products.

Two Types of Results from a Charpy Test

- Energy Value (in Joules) – Shows how much energy the material absorbed.

- Fracture Type (Looks)

- Ductile fracture: Rough, stretched-out surface

- Brittle fracture: Smooth, shiny surface with little bending

These two results give a full picture of what happened.

Where is Charpy Impact Testing Used?

- Buildings: Testing steel and beams

- Cars: Checking crash safety parts

- Planes: Testing materials for flying at high speed

- Plastic Products: Making sure they won’t break easily

- R&D Labs: Choosing and improving materials

ASTM Standards for Charpy Impact Testing

The folks at ASTM (American Society for Testing and Materials) set the rules to keep things consistent. The big one is:

- ASTM E23: Covers everything from how to shape the sample to how to swing the hammer. It’s the gold standard for Charpy and Izod tests.

Other standards to know:

- ASTM A370: General rules for testing steel, including impact tests.

- ASTM E208: Focuses on finding the temperature where steel gets brittle.

These standards make sure everyone’s on the same page, whether you’re testing in New York or New Delhi.

Difference Between Izod and Charpy Impact Tester

You might’ve heard of the Izod test, which is like the Charpy test’s sibling. They both measure toughness, but they’ve got some key differences. Here’s a quick rundown:

| Feature | Charpy Impact Test | Izod Impact Test |

| Sample Position | Lies flat, supported at both ends | Stands upright, clamped at the bottom |

| Notch Direction | Notch faces away from the hammer | Notch faces the hammer |

| Main Standard | ASTM E23 | ASTM D256 |

| Common Materials | Metals like steel | Plastics and composites |

| Energy Range | Higher (150–300 joules) | Lower (up to 124 joules) |

Charpy is the go-to for metals, while Izod is more common for plastics. Both are awesome, but they’re tailored for different jobs.

Final Thoughts:- Still One of the Best Tests Around

The Charpy Impact Test is still widely used because it’s fast, reliable, and gives clear results. If you work in cars, planes, construction, or material science, this test is a must-have.

Need a Quality Charpy Impact Tester?

Talk to Presto Group – Experts in advanced testing instruments offering the best Charpy Impact Tester price in the industry.

Call: +91 9210 903 903

Email: info@prestogroup.com