In the ever-changing world of materials science and quality assurance, the frictional behaviour of materials is of key interest. The coefficient of friction, a parameter of high priority in material testing, plays a critical role in characterizing the interaction between two surfaces in relative motion. Whatever your application may be from packaging films to textiles and to engineered components, an advanced coefficient of friction measurement instrument will provide you with reproducible and reliable results. This blog dives into friction testing machines, methodologies, and their indispensable role across industries in detail.

Formula:

Formula: μ= F/N

Where:

This dimensionless number helps engineers and scientists evaluate the slip and grip characteristics of materials, crucial for applications such as:

At Presto, a material testing solutions provider, it is innovation and precision in our products. Our COF measuring devices are highly engineered to deliver precise, replicable results. With features like:

Presto’s COF testers empower users to uncover nuanced material characteristics, fostering product excellence and reliability.

Modern COF testers provide precision and repeatability, which are very valuable in R&D and quality assurance. Such machines can measure both static friction (force to begin motion) and kinetic friction (force to continue moving). A more advanced tester for kinetic friction can find minuscule differences between textures, coatings, and even lubrication, with unmatched insight into material performance.

A high-technology COF testing machine consists of:

The machine's ability to automate testing cycles minimizes human error, enabling accurate replication of test conditions.

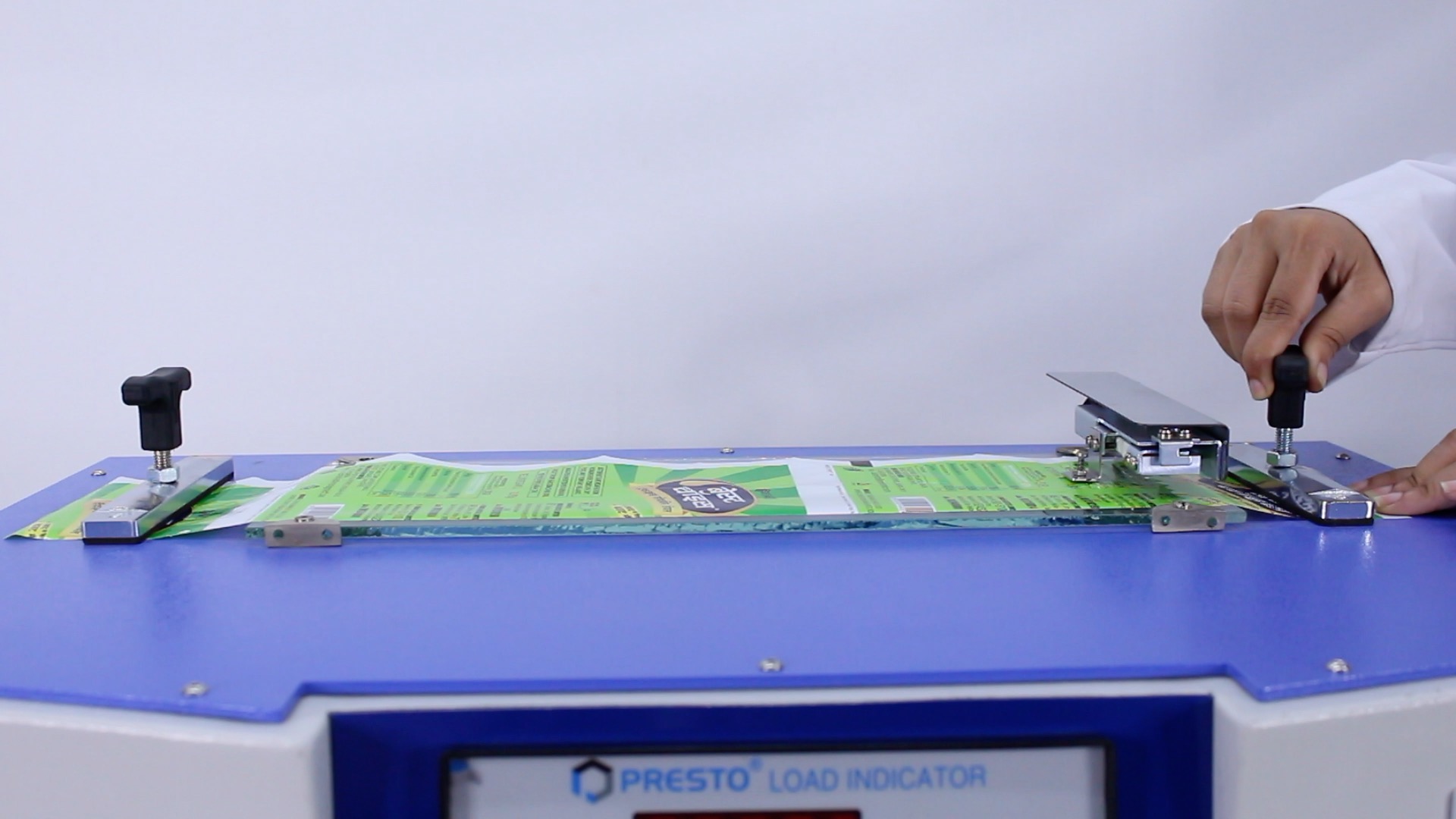

The process involved is as follows: Place a test material on a flat, horizontal platform Attach a sledge of defined weight to the material Move the sledge at a constant speed, with the frictional force recorded.

The obtained COF values can help understand the material behaviour under specific conditions and, thus, assist in the proper selection of the material and process optimization.

1. What materials can be tested with a Coefficient of Friction Tester?

Any material, be it plastic, metals, ceramics, textiles, or even biological surfaces, may be tested with a COF tester

2. Can a Coefficient of Friction Tester or Kinetic Friction Tester be used for packaging materials?

Absolutely. Packaging films, cartons, and labels are often tested to ensure optimal slip properties for manufacturing and end-user functionality.

3. Coefficient of Friction Tester vs. Tribometer: What are the distinctions?

While COF measures static and dynamic friction mainly, a tribometer can, additionally, check wear factors, lubricants, or even long-term testing.

Investing in a high-quality coefficient of friction measurement device is not just about meeting compliance standards; it’s about unlocking material potential. Whether you’re in packaging, textiles, or engineering, a reliable friction testing machine ensures that your products meet and exceed performance expectations. Trust industry leaders like Presto to deliver precision, innovation, and unparalleled support for all your COF testing needs.

Phone: +91 9210 903 903

Mail: info@prestogroup.com

Connect with us for your business enquiries. Generally, we respond within one or two working days.