- /

- Article / Stepwise Guide to Conducting a Vacuum Leak Test on Packaging

Stepwise Guide to Conducting a Vacuum Leak Test on Packaging

In food, pharma, and consumer goods industries, packaging must be completely secure. Even a small leak can affect product quality, safety, and shelf life, leading to recalls or unhappy customers. Vacuum leak testing is a reliable way to detect Such defects include pinholes, cracks, seam failures, weak seals, or punctures in the packaging material. helping ensure packages meet strict quality standards and products remain safe and intact. This blog gives a clear, step-by-step guide to doing a vacuum leak test on packaging, diving into the principles, equipment, and best tips for getting it right.

What is a Vacuum Leak Test?

A vacuum leak test is a non destructive method to find leaks in sealed packaging. It works by creating a vacuum environment around the package and watching for changes that shows air or liquid escaping.

This test is capable of identifying weak seals, pinholes or packaging errors. Using a vacuum leak tester, businesses will be able to ensure that their line of products are up-to-par with packaging quality control guidelines and ship it out for customers.

Principle of Vacuum Leak Test

The vacuum leak test principle is simple:

- The package is placed in a sealed chamber of a vacuum leak test unit.

- Air is removed from the chamber, creating a vacuum around the package.

- Any leak in the packaging lets air escape, which can be seen as bubbles (in water) or package deformation.

- Operators can detect leaks immediately and fix the problem.

This method works best for flexible packaging, blister packs, pouches, and vacuum-sealed containers.

Equipment Needed for Vacuum Leak Testing

To do a proper vacuum leak test, you will need:-

- Vacuum leak test machine or vacuum leak tester

- Vacuum chamber (usually comes with the machine)

- Water bath (for bubble testing if required)

- Timer and vacuum gauge to monitor

- Safety gloves and tools

Modern vacuum leak test machines are digital and automatic. The vacuum leak tester price depends on size and brand, but a good machine saves money in the long run by reducing faulty packaging.

Stepwise Guide to Conducting a Vacuum Leak Test

Follow these steps for effective vacuum leak testing:

Step 1: Prepare the Package

- Make sure the package is sealed properly and has no damage. Remove labels or tape that can affect the test.

Step 2: Prepare the Vacuum Leak Test Unit

- Place the package inside the vacuum leak test unit.

- If using water, fill the chamber partially according to instructions.

- Check that vacuum gauge and other instruments are calibrated.

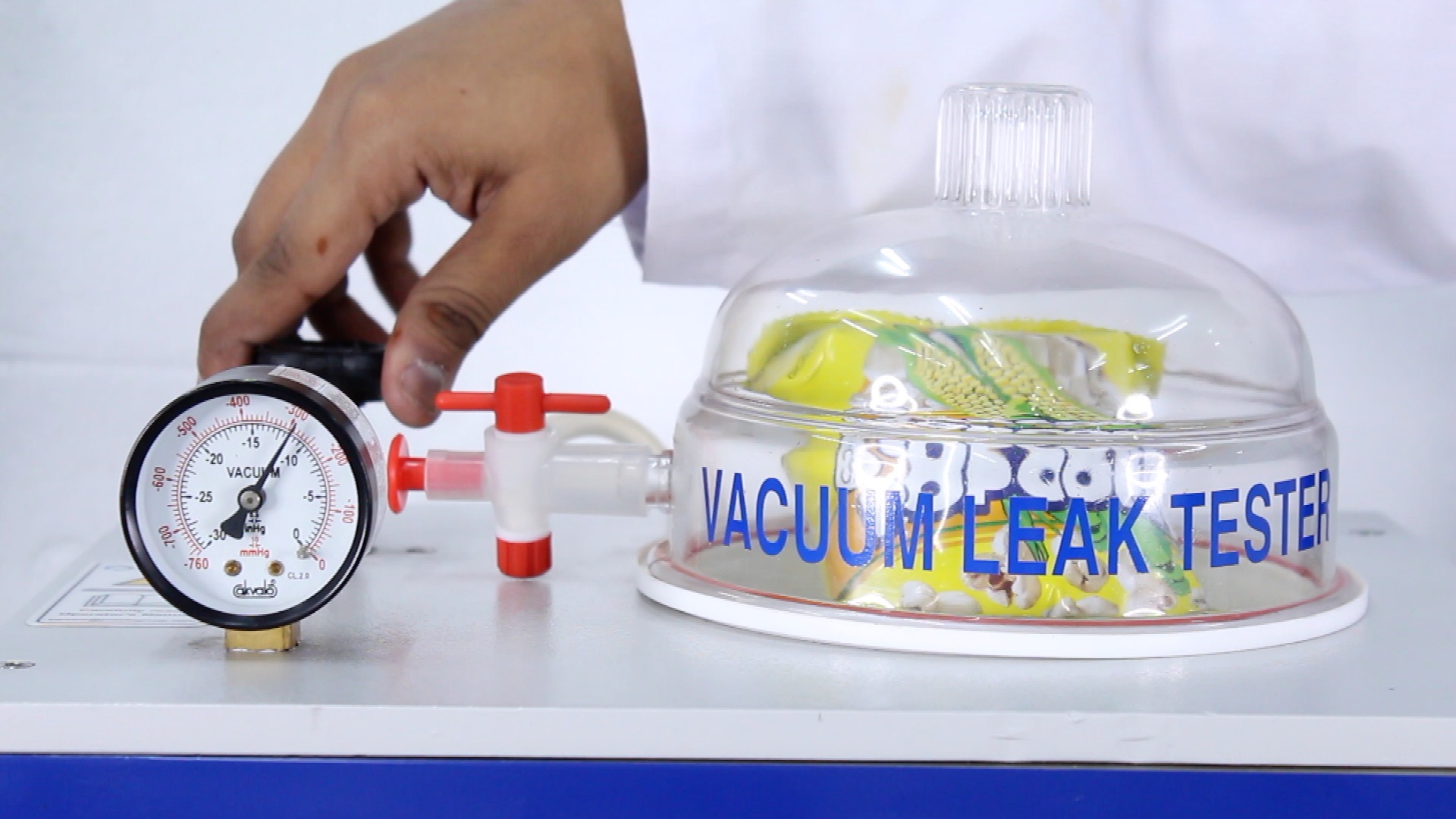

Step 3: Create the Vacuum

- Switch on the vacuum pump to remove air from the chamber.

- Watch the vacuum gauge. Different packages need different vacuum levels as per product type.

Step 4: Check for Leaks

- Observe the package carefully.

- For water tests, look for bubbles escaping from the package.

- For dry tests, watch for swelling or deformation that indicates a leak.

Step 5: Record the Results

- Note vacuum pressure, time, and observations.

- Packages with leaks should be removed and checked for weak seals or material damage.

Step 6: Take Corrective Actions

- Adjust sealing machines if needed.

- Retest after adjustments.

- Keep records for packaging quality control purposes.

Advantages of Vacuum Leak Testing

Using a vacuum leak test machine provides many benefits:

- Non-destructive – Most tests don’t damage the package.

- Reliable – Detects small pinholes and weak seals.

- Quality assurance – Ensures consistent product quality.

- Cost-saving – Reduces product waste and recalls.

- Versatile – Works for food, pharma, and other products.

Types of Vacuum Leak Testing

Depending on your product, vacuum leak testing can be done in different ways:

- Dry Vacuum Testing – No water is used. Leaks are seen from deformation.

- Wet Vacuum Testing – Package is submerged in water, bubbles show leaks.

- Digital Automated Testing – Modern machines give pass/fail results automatically.

Important Tips for Effective Leak Detection

To get accurate results:

Set correct vacuum levels and time for the material.

- Make sure package surfaces are clean.

- Calibrate vacuum leak test units regularly.

- Use trained operators to read results.

- Compare with standard reference packages for verification.

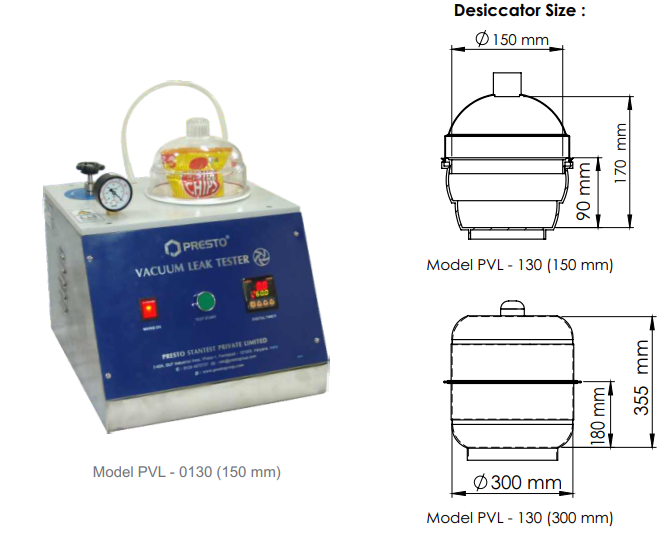

Best Choice for Reliable Vacuum Leak Testers – Presto Group

Presto Group is a leading name in India for high--quality vacuum leak tester and other leak test equipment for packaging and many more lab testing equipment. With broad expertise in packaging quality control solutions, they provide reliable, durable, robust, and precise machines suitable for various industries. Their expert support, competitive vacuum leak tester prices, and commitment to excellence make them the best choice for manufacturers seeking 100% leak-free packaging.

End Note

A vacuum leak test is one of the most crucial steps in ensuring that your products packaged are safe, well-sealed and high-quality in terms of manufacturing. Through following a simple step-by-step methodology, it detects leaks fast and avoids shipping defective products to your customers.

A decent vacuum leak test machine or vacuum leak tester enhances packaging quality control, minimizes product wastage and increases customer trust. And a testing vacuum seal whenever you use it ensures that every pouch stays pristine, whether your storing food, pharmaceuticals, valuables or other sensitive goods.

Buy the right leak test machine for packaging, today and never allow your package to defy safety and quality.

Ready to improve your packaging quality? Contact Presto Group today to explore top-notch vacuum leak testers and other leak test equipment for packaging. Ensure every package is leak-free, safe, and ready for the market!

Call us:- +91 9210 903 903

Email: info@prestogroup.com