In many industries, products need to be strong and long lasting, and this is where abrasion resistance becomes very important. Abrasion resistance simply means how well a material can handle friction, rubbing, or scraping without wearing out too quickly. For example: rubber in car tires, fabric in clothes, paints, coatings, or even packaging materials all need to resist abrasion so they last longer and perform well.

To check this property, companies use special machines like the Abrasion Resistance Tester (or abrasion testing machine). In this blog, we will explain what abrasion resistance is, why it matters in industries, the main testing methods, international standards, formulas used, and the general testing procedure.

Abrasion resistance is the ability of material to resist surface loss due to mechanical wear caused by repeated friction or contact. In simple terms, it measures how long a material can withstand damage when rubbed against another surface.

For example:-

The higher the abrasion resistance, the more durable and reliable the material is.

| Industrial Importance | Explanation |

| Quality Control | It ensures that the factory-produced materials are strong and durable enough before you give them to the customer. |

| Product Life Extension | Materials that have high abrasion resistance can last for a much longer time, which helps in reducing the extra cost of replacing them again and again. |

| Safety & Compliance | In industries like automotive, aerospace, and construction, having good abrasion resistance is very important because it directly affects the safety and compliance of the products. |

| Brand Reputation | When materials deliver an excellent performance constantly Users have a faith of such people and the brand as well is more reliable. |

| Cost Efficiency | Products damaging or failing too early is avoided, saving production costs and preventing additional warranty claims to improve the overall cost efficiency. |

Industries like rubber, plastics, textiles, packaging, automotive, paints, coatings, and construction depend heavily on abrasion testing for product validation.

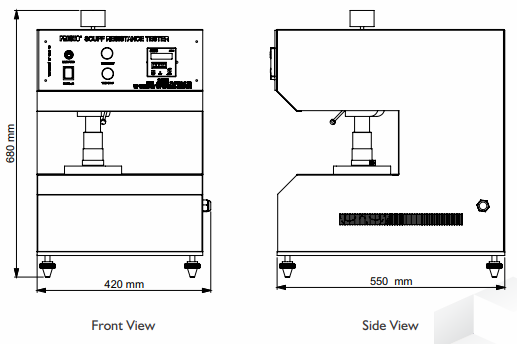

An abrasion testing machine is design to measure the wear resistance of materials under controlled conditions. Different models are available depending on the material type.

Common Types:-

These machines simulate real-life wear conditions, giving reliable data to manufacturers for research, product development, and quality assurance.

Several test methods are used worldwide to measure abrasion resistance. The choice depends on material and application.

Taber Abrasion Test (ASTM D4060)

DIN Abrasion Test (ISO 4649, ASTM D5963)

Martindale Abrasion Test (ISO 12947)

Dry & Wet Abrasion Tests

Though the exact procedure varies with the test standard, the general steps are:-

Sample Preparation

Machine Setup

Test Parameters

Test Execution

Measurement

The standard formula depend on method, but the general calculation is:

Abrasion Loss (%) = [(Initial Weight – Final Weight) / Initial Weight] × 100

For rubber (DIN Test):

Abrasion Resistance = Loss in Volume (mm³) = (Weight Loss × Constant) / Density

Here, the constant depends on the test standard. Lower volume loss = higher abrasion resistance.

A typical abrasion resistance tester consists of:-

This design ensure uniform wear and accurate measurement of abrasion resistance.

In textiles, abrasion resistance determine how well fabrics can withstand surface wear caused by rubbing. Applications include:-

The Martindale Abrasion Test is most widely accepted method in textile industry. Fabrics are categorized based on the number of rub cycle they can endure before showing visible wear.

Some materials are naturally more abrasion-resistant due to their structure and composition:-

Choosing right abrasion-resistant material depends on the application and operating condition.

Several standards guide the testing of abrasion resistance:-

Compliance with these standards ensure global acceptance and reliability of test results.

A digital abrasion resistance tester ensure:

For manufacturers, this translates to improved product quality, reduced rejection rate, and stronger market competitiveness.

Abrasion resistance testing is an essential part of quality assurance across industries like rubber, plastics, textiles, packaging, paints, and coating. Using an abrasion resistance tester, manufacturers can evaluate durability of materials, ensure compliance with global standards, and deliver long-lasting, reliable products.

Whether you need a friction test machine for rubber, textiles or coating, it is important to choose the right tool for the exact result. With increasing customer expectations and global competition, friction resistance is no longer optional - it is necessary for existence and success.

Contact us today to get the best testing solution for your industry.

![]() Phone: +91 9210 903 903

Phone: +91 9210 903 903

Mail: info@prestogroup.com

Ensure your products meet the highest durability standards with Presto’s advanced abrasion testing machines.