20-8-2018

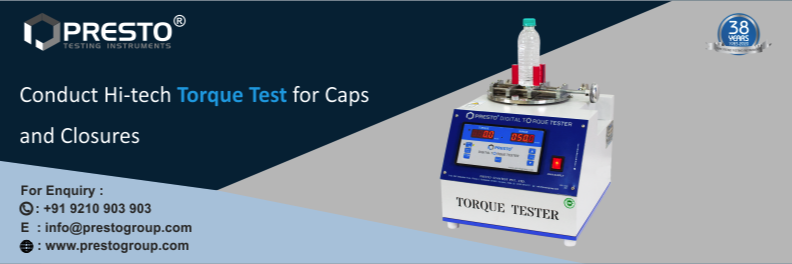

Bottle caps and closures are the most sensitive part of a bottle when ensuring its quality as it is the only barrier between outside contamination and inside content. The bottle cap are tested for its material quality its sealing nature, leakage resistance, and its torque quality. The bottles are specified under several quality standards and requirements. The sample fulfils all passes the production and forwarded to the filling line. Often companies set a particular amount of torque for the closure and it must follow the same. However, it needs an efficient system to measure the torque value.

To know more information about its features, price, and technical specifications, give us a call at +91 9210903903 or email us at info@prestogroup.com.

Related Blogs

Salt spray test checks corrosion resistance of materials using a salt spray chamber. Essential for quality control in coatings, metals, and finishes.

Hot Air Oven uses dry heat for sterilizing glassware and metal tools, while an Autoclave uses steam under pressure—ideal for liquids and medical items.

GSM of fabric (Grams per Square Meter) indicates fabric weight and thickness. Higher GSM means denser, heavier fabric; lower GSM means lighter, thinner fabric.