16-10-2018

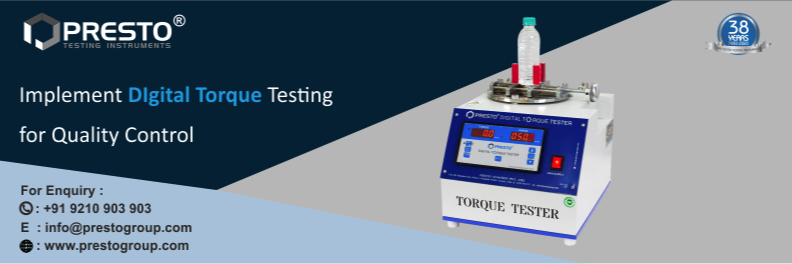

Starting the topic, first let us understand very clearly what is torque and why the Torque testing is required for Quality Control. ‘Torque’ is a force applied in a specified angular direction to turn something. In this case we are targeting the PET bottle Caps or container closure systems. For instance the force required to turn a bottle cap for opening it or closing down is a very simple example of torque. Testing the amount of torque required for the cap to close or open is necessary to ensure quality of the product. By conducting such quality test practices one can not only assure the customer of its performance but can also find out and resolve the root cause of many defects. Torque of any object can only be measured using a test machine such as Torque Tester Digital.

Using such test machinery for conducting quality control in PET bottles is a necessary step to perform.

To know more information about its features, price, and technical specifications, give us a call at +91 9210903903 or email us at info@prestogroup.com.

Related Blogs

Hot Air Oven uses dry heat for sterilizing glassware and metal tools, while an Autoclave uses steam under pressure—ideal for liquids and medical items.

GSM of fabric (Grams per Square Meter) indicates fabric weight and thickness. Higher GSM means denser, heavier fabric; lower GSM means lighter, thinner fabric.

Discover why abrasion resistance is crucial for packaging, textiles & plastics. Learn how it's tested (Martindale, Taber, DIN) & why it boosts durability. Save costs with wear-resistant materials!