Packaging is the technology of protecting products for storing, sale and distribution. Packaging should be done so that the products are protected to maintain it in its original position. According to the World Health Organisation, the wastage of foods in the third world countries is as high as 50% and in a developed nation, it is 3%. The difference lies due to the good quality of packaging. It helps in promoting products by establishing brand recognition. Packaging also conveys warnings and instructions on products with content ingredients. Poor quality of packaging brings a bad reputation to the company. Packaging involves materials like foil, labels, film etc. The major quality of packaging is its strength, appearance and quality. The manufacturers need to check each of these properties thoroughly to avoid any defect in the quality of the product.

Foil wrapping keeps the food warm and fresh for a few hours. It can stand high temperatures and covers the food by providing nourishment to the material. It acts as a good insulator and widely used packing material. Aluminium foil has a thickness between 0.00017 and 0.0059 inches. Manufacturers perform testing on them to serve the purpose in various applications as per its strength.

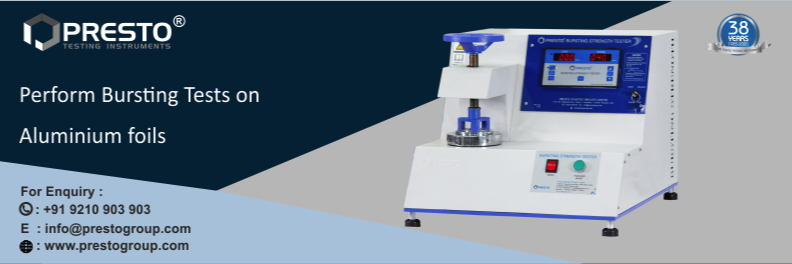

Bursting strength tester- digital Pneumatic with the printer is a device to test the bursting strength of foil paper.

The equipment has high tech features with pneumatic control to give pressure. The pneumatic application operates with hydraulic pressure that ensures vertical load without any manual interference. It can be used to test the bursting strength of corrugated paper, boards, foils etc. the equipment complies with various standards. By using the high quality testing machine, properties and quality of packaging products are to be tested.

Presto

Bursting strength tester is designed in such a way that it can be operated single handed with advanced locking feature. Solid holding braces without any slippage. Feather control touch with repeatable tests to be performed. It can hold up to 9 readings. Zero mistake test with the use of pneumatic force in all directions. The unique feature is the printer facility. The user can have a print of the test result. It is important to check the bursting quality to check the value control in many businesses.

Why Bursting Strength Testing is Essential for Aluminium Foils

Bursting strength testing plays a vital role in maintaining the integrity of foil packaging during storage, handling, and transportation. In industries such as pharmaceuticals, food, and FMCG, where hygiene and product preservation are critical, weak packaging can lead to contamination and spoilage. By performing bursting tests, manufacturers can ensure that the foil does not rupture under pressure, especially when exposed to stress conditions like stacking or external force. This type of testing not only enhances customer satisfaction by maintaining product freshness but also helps businesses reduce losses due to damaged packaging. With accurate bursting strength data, quality control becomes more efficient and reliable.

Frequently Asked Questions (FAQs)

Q1. Why is bursting strength important for aluminium foil packaging?

Bursting strength determines the maximum pressure the aluminium foil can withstand before rupturing. This is crucial for maintaining the integrity of packaged products during storage, handling, and transportation, especially in food, pharmaceutical, and consumer goods industries.

Q2. Can the bursting strength tester be used for materials other than aluminium foil?

Yes, Presto’s Bursting Strength Tester is versatile and can also be used to test the strength of corrugated boxes, paperboards, laminates, and other flexible packaging materials. It ensures consistent and accurate results across various substrates.

Q3. What standards does the bursting strength tester comply with?

Presto’s bursting strength testing equipment complies with various national and international testing standards like ASTM and ISO, ensuring reliable and globally accepted test results. You can contact the Presto team for detailed standard compliance information.

To know more information about its features, price, and technical specifications, give us a call at +91 9210903903 or email us at info@prestogroup.com.