Gaurav Malhotra

04-5-2017

Light weight - In comparison to other packaging materials like plastic and wood, corrugated fiberboards are much lighter in weight and are flexible, especially the sheets. The raw material used to make these boards is paper, therefore, these can be recycled and reused easily and are biodegradable in nature.

There are many people who are not satisfied with these answers. For them, let's get into technicalities of it.

Shock Absorbent - Corrugated fiberboard is a good shock absorbent. Meant to sustain the harsh conditions of the warehouses and transportation, it has a cushioned structure which disperses the force subjected to it without affecting the contents inside it.

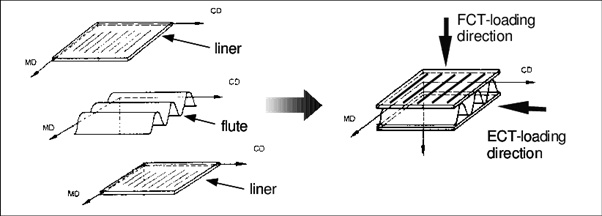

When we say, corrugated or corrugator. we are referring to a structure having ridges and furrows. Any force applied to the surface is distributed along these ridges and furrows.

These corrugators make the fiberboard or sheet strong to bear the impact or force without any damage, in other words, making the sheet highly resistance to compressive force or crushing.

When we test the quality of the corrugated box, we analyze its resistance against the force applied vertically on its flutes and from the top on its flutes. Another test that we perform is Ring crush test, in which a strip of the sample is cut and made a ring out it by joining the ends. A pressure is applied on the ring from the top. In this case, the resistance would be more as the force applied is being dispersed across the circumference and then to the walls of the sample.

Presto's digital model for edge crush testing is a perfect instrument that fulfils the demand of all these 3 tests. It has separate fixtures to perform RCT, ECT and FCT on the same instrument. The sample can be subjected to a force of up to 100Kgf (gravitation metric unit of force). Prime features that you can bank upon:

Standard - IS 7063 - 2. According to BIS, A rectangular test sample is placed between the platens of crush tester with the flutes perpendicular to the platens. A compression force is applied to it until failure occurs and maximum force sustained by the sample is measured.

Corrugated boxes or sheets does not require very high-end testing instruments to for its quality checking. A cost-effective testing lab can be easily set up, raw materials can be easily procured, downgauging can be easily done, reusing is easy; All these features and easy testing makes corrugated fiberboard favorite among packagers.

Related Blogs

A Tensile Tester is designed to pull a material sample until it breaks. It helps engineers measure important properties like tensile strength, elongation at break, yield point, and more.

UV Chamber simulates sunlight to test material durability against UV rays, helping ensure long-term quality and resistance to environmental damage.

Salt spray test checks corrosion resistance of materials using a salt spray chamber. Essential for quality control in coatings, metals, and finishes.