Corrugated packaging is very lightweight in comparison to other packaging material like plastic and wood. Corrugated fibre boards are not only lighter in weight but also flexible for moulding of different shapes and sizes. Apart from all this, they can be reused and recycled efficiently. Also, they are biodegradable in nature and are completely environment-friendly. Despite having all these properties, the technical specifications of the fibre make it more preferable choice for different packaging applications.

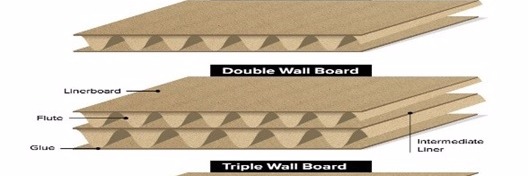

Corrugators are sandwiched between two linear boards to make a corrugated fibre board. Corrugators are the zig-zag structure having ridges and furrows. This gives the shock absorbance properties to the structure. The cushion formed due to corrugators protects the contents of the packing from any damage. As any force applied on the surface gets distributed along this corrugated structure.

It makes the sheets highly resistant to jerks that a packaging may receive during transportation and storage.

Corrugated cartons are available in different grades in which the heights and density of corrugators or flutes are changes. Also, multi-layer flutes can also be procured, e.g. 3 plies or 5 plies. Depending upon the quality grade, the application is decided. The quality of a material can only be defined after testing

the different properties.

For a CFB, most of the tests are performed on the flutes.

- Ring crush test

- Flat crush test

- Edge Crush test

Presto’s digital model for edge crush testing is a perfect instrument that fulfils the demand of all these 3 tests. It has separate fixtures to perform RCT, ECT and FCT on the same instrument. The sample can be subjected to a force of up to 100Kgf (gravitation metric unit of force). Prime features that you can bank upon;

· It comes with a microprocessor based LED display for precise and accurate test results.

· It stores the Peak value of the sample which is the maximum force tolerated by the sample before deforming.

· It has an inbuilt calibration system for error-free operation.

· It comes with an electromechanical loading system.

· Auxiliary key support to control the unauthorised access

Testing of corrugated boxes can be done easily without using any complicated test machines. It is a very cost-effective material used for packings. The test lab can be set easily. Reusing, downgauging, recycling is convenient uses of used cartons. All these features and easy testing makes corrugated fiberboard favourite among packagers.

Related Blogs

Hot Air Oven uses dry heat for sterilizing glassware and metal tools, while an Autoclave uses steam under pressure—ideal for liquids and medical items.

GSM of fabric (Grams per Square Meter) indicates fabric weight and thickness. Higher GSM means denser, heavier fabric; lower GSM means lighter, thinner fabric.

Discover why abrasion resistance is crucial for packaging, textiles & plastics. Learn how it's tested (Martindale, Taber, DIN) & why it boosts durability. Save costs with wear-resistant materials!