- /

- Blog / Why Material Toughness Matters: The Role of Izod Charpy Testers

Why Material Toughness Matters: The Role of Izod Charpy Testers

Imagine this: a cutting-edge automotive company is designing a new electric vehicle. Every component needs to be lightweight yet incredibly strong and safe. They select a promising new polymer composite for the bumper system. It passes static strength tests with flying colours. But during simulated crash testing, the bumper shatters unexpectedly on impact, failing catastrophically. Why? Because static strength only half the story. The missing half of the puzzle was impact resistance, or toughness – a material's capacity to absorb energy and deform on impact without breaking.

This situation is an important one in material science and engineering: knowing how materials respond to dynamic loads. This is where the invaluable Izod Charpy Impact Tester is essential.

Why is Impact Testing So Important?

The information obtained from these tests is crucial in many industries for a number of important reasons:

Safety and Reliability: Preventing parts in automobiles, aircraft, buildings, and even household appliances from failing catastrophically under sudden loading or impact.

Quality Control: Confirming raw materials and finished goods consistently have necessary toughness standards. Batch-to-batch differences can be rapidly detected.

Material Selection: Comparing the impact performance of alternative materials (such as different grades of steel or plastics) to select the most appropriate for a particular application.

Research and Development: Defining new materials and determining how variables such as temperature, additives, or processing influence their impact properties.

Compliance: Conforming to industry standards and government regulations that frequently require certain impact strength values.

Cracking the Code: The Difference Between Izod and Charpy Impact Tests

Though commonly done on the same equipment (thus the designation Charpy and Izod test machine), the Izod and Charpy tests vary fundamentally in the position and impact location of the specimen:

Difference between Izod and Charpy impact test

(Charpy Test)

Specimen Setup - A square bar, typically notched in the centre, is placed horizontally and supported at each end.

- Impact: The pendulum impacts the specimen directly across from the notch.

- General Use: Extremely common for testing metals, but there are also standardized tests for plastics (e.g., ISO 179).

(Izod Test)

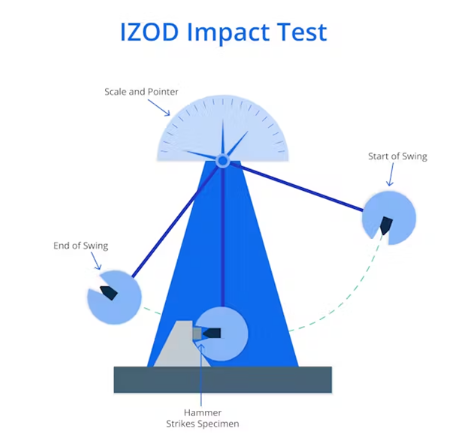

Specimen Configuration: The specimen is clamped vertically, held firmly at one end like a cantilever beam. It often has a V-notch at the clamped end.

Impact: The pendulum hits the cantilevered end on the same side as the notch.

General Application: Generally applied for Izod Charpy impact testing of plastic materials and composites (e.g., ASTM D256, ISO 180).

Izod impact testing machine diagram

Plastic Spotlight: A Special Challenge

Izod Charpy impact testing of plastics requires particular notice. Plastics show a very broad variety of behaviors upon impact, with high dependence on:

Temperature: Numerous plastics become much more brittle with decreasing temperatures.

Notch Sensitivity: The shape and existence of a notch can lower the impact strength of some plastics quite drastically.

Strain Rate: The rate of the impact determines the response of the polymer chains.

Processing: The manner in which the plastic was moulded or extruded may cause internal stresses or orientations which influence toughness.

The Izod test, for example, is particularly popular with many plastic applications since its cantilever design and notch shape tend to simulate practical stress concentrations quite well with these materials.

Getting to Know Your Testing Machine: Instruction Books and Expenses

Running an impact tester needs accuracy. The Izod Charpy impact tester manual is not merely a handbook; it's an important manual that specifies:

1. Proper machine setup and calibration procedures.

2. Standardized specimen preparation and mounting.

3. Safe operating procedures.

4. Regular maintenance to guarantee ongoing accuracy.

5. Troubleshooting for frequent problems.

Stricter adherence to the manual is crucial in order to gain accurate, repeatable results and maintain operator safety.

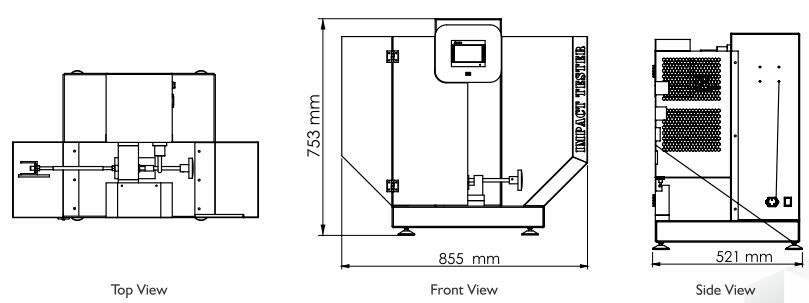

In the case of Charpy Impact test Machine Price (typically for combined Izod/Charpy models), it may differ considerably. Cost-determining factors are:

Capacity: The highest impact energy (expressed in Joules or ft-lbs).

Digital vs. Analog: Digital models have simpler readings, data logging, and calculation capabilities.

Automation: There are completely automated specimen handling systems available for high-throughput laboratories.

Quality: Established brands tend to cost more but provide greater reliability and support.

Safety Features: Better guarding and braking systems.

Although the initial outlay may appear to be a lot, it is tiny compared to the expenses of product failures, recall, or safety accidents caused by poor material testing. It's an investment in brand reputation, quality, and safety.

Case Study: From Brittle Bins to Reliable Resins

Problem: An industrial storage bin producer using recycled plastic was experiencing a growing number of customer complaints about bins cracking and breaking upon impact or being dropped, particularly in cold warehouse settings. Warranty returns were on the rise, harming their reputation.

Investigation: The firm based all their information on material properties on supplier datasheets. They had no internal capability to validate the impact strength of the batches of recycled plastic they were purchasing, which had different compositions.

Solution: Izod Charpy Impact Testing for plastic materials. Following the Izod Charpy impact tester manual to the letter, their quality assurance team ran a standard test regime according to ASTM D256 (Izod for Plastics). They tested each batch of recycled plastic feedstock samples for both room temperature and a cooler simulated warehouse temperature.

Result: The testing soon showed large batch-to-batch differences in impact strength. Certain batches were well below the toughness requirement, particularly at lower temperatures. With this information, the company:

- Applied more stringent acceptance criteria to their recycled plastic suppliers.

- Collaborated with suppliers to enhance the consistency and impact characteristics of the feedstock.

- Rejected impacted test-failed batches prior to production.

- In just six months, cracking-related warranty claims fell by more than 80%. Customer satisfaction increased, and the business became more entrenched in its reputation as a vendor of hard-wearing, dependable storage equipment. It's a perfect illustration of expertise and trustworthiness (E-E-A-T) paying off directly in business benefits.

Take Control of Material Performance

Measuring and understanding impact resistance is no longer a choice in today's competitive market; it's a necessity. The Izod Charpy Impact Tester gives you the vital information necessary to design safer products, maintain consistent quality, and innovate with new materials with confidence.

Are you prepared to make sure your materials are impact-resistant? Don't leave toughness to chance.

Discover our selection of Charpy and Izod test machine.

Call us today for a custom quote or to talk about your individual testing needs.

Frequently Asked Questions (FAQs) about Izod Charpy Impact Tester

Q1. Is calibration of an Izod Charpy Impact Tester required?

Ans. Definitely. Periodic calibration (normally once a year, or according to applicable standards such as ASTM or ISO) is essential. It guarantees that the machine correctly measures energy absorption by checking elements such as pendulum release height, bearing friction, and indicating mechanism. Without calibration, the testers may provide inaccurate results, resulting in misjudged material evaluation and potential product failure.

Q2. How does the tester measure impact strength?

Ans. A tester measures the impact strength as the amount of energy absorbed when a standardized sample fractures. It does so via a pendulum mechanism:

- The pendulum is brought to a given height, allowing it a fixed potential energy.

- Released and allowed to swing down and hit and break the specimen.

- Energy expended to break the specimen converts the pendulum's kinetic energy.

- The tester records the height to which the pendulum swings after it has shattered the specimen.

- The difference between the original potential energy and the energy still present (calculated from the height of the post-impact swing), allowing for any losses due to friction, is the energy absorbed by the specimen – its impact energy or toughness.

Q3. What are the normal testing norms adopted in Izod and Charpy tests?

Ans. There are many international and industry standards that dictate Izod and Charpy testing to provide consistency and comparability of results. Always use the standard applicable to your material and application.

Q4. What are the materials that one can test with an Izod Charpy Impact Tester?

Ans. These tests are flexible and are mainly utilized for:

- Metals: Particularly through the application of the Charpy method to establish ductile-to-brittle transition temperatures.

- Plastics: Both Izod and Charpy approaches are commonly applied to determine toughness.

- Composites: Measurements of impact resistance of reinforced materials.

- Ceramics and Polymers: Modified setups may be necessary, but impact properties can be measured.

Q5. Which industries use the Izod Charpy Impact Tester?

Ans. Due to the intrinsic importance of impact resistance, the testers find application in a broad range of industries, such as:

- Vehicle: Bumper, dashboard, structural part testing.

- Aerospace: Testing of fuselage, wing, and engine component

- materials.Construction: Testing structural steels, polymers in fixtures, piping.

- Polymer and Plastics Production: R&D and quality control for compounds and resins.

- Metal Production and Fabrication: Quality control for aluminium alloys, steels, etc.

- Consumer Products: Testing of plastics in electronics casings, toys, protective equipment, appliances.

- Research Organizations and Academia: Basic material characterization.

Quality Control Laboratories: Third-party testing and certification.

Looking for the Best Izod Charpy Tester Price?

Get in touch with our experts today to receive a competitive quote and discover the perfect impact testing solution for your needs.

Call us now: +91 9210 903 903

Email: info@prestogroup.com

Don't miss out on precision, performance, and affordability—contact us for the best Izod Charpy Tester Price today!

Recent Blogs

- Controlled Humidity Chamber: Environmental Testing Methods, Applications & Packaging Testing Use Cases

- Spectrophotometer & Portable Spectrophotometer: Working Principle and Laboratory Applications

- Paint Tester & Coating Testing Equipment: Types, Testing Process, and Industrial Applications

- Moisture Meter: Types, Working Principle & Applications in Industrial Labs

- Environmental,Pharmaceutical, and Research Laboratories in BOD Incubator