What is peeling strength?

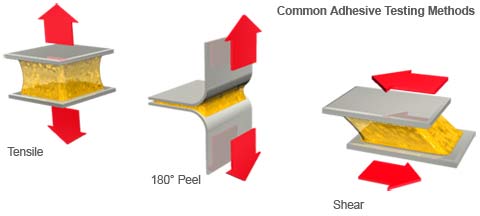

As the name defines, the force required to separate the bonding of two self-adhesives or bonded materials is called peeling strength. It is a very important factor for the packaging industry. Adhesions having low peeling strength would be disqualified by quality control, even after having premium corrugates boards or plastic packets. For force sensitive products like electronics, ceramics and glass; low peeling strength can lead to damage of inside contents of packaging. On the other hand, heavy products like wooden articles; damaged packaging due to poor adhesion may lead to the destruction of lamination of wooden articles. Therefore, the strength of supporting components like adhesive tapes and seals have to be taken special off.

What is peel test?

The measurement of the force required to separate the two bonded material is called peel test. Testing instruments like Peel strength tester can be used to easily measure the force applied. In this test, the sample is placed on the plate under specified conditions e.g. temperature. A force measuring instrument measure the force applied to remove the sample from the testing plate.

Why it is important in packaging?

Adhesives play a very important role in the packaging industry, especially, plastic packaging and corrugated box packaging. Measuring bursting strength, tensile strength etc. are important factor in quality controlling. Adhesive tapes, which are used to close the opening of the packaging often gets ignored. Adhesive tapes, if not tested for their peeling strength would lead to failure of packaging. This may result in the spoiled lot. Especially in ecommerce industry, where presentable delivery of the product is the reputation building clock of e-tailer and distributor. If end user gets tempered seal, or damaged packages; it becomes eligible for straightaway return policy. This sometimes is not good for the distributor and for end user. For instance, something very urgent has been ordered and has to return due to the negligence of packager; say a birthday gift.

E-commerce packagers are now taking special care of this thing. Many of them have their in-house peel strength tester at their warehouses. Quality control team ensures that every adhesive tape or packets with seals should be tested before used in the packaging.

How to conduct peel strength test for best results?

The foremost requirement is conditions. Assuming the conditions in which adhesives are going to use should be simulated. If are being used on cartons which are supposed to carry the load of 20 kg, equivalent load has to be simulated. If are being used in plastic packaging for a humid environment, equivalent humidity has to be simulated to adjudge its efficiency.

Certainly, use of testing instruments is an inseparable part of the packaging industry.

Related Blogs

A Tensile Tester is designed to pull a material sample until it breaks. It helps engineers measure important properties like tensile strength, elongation at break, yield point, and more.

UV Chamber simulates sunlight to test material durability against UV rays, helping ensure long-term quality and resistance to environmental damage.

Salt spray test checks corrosion resistance of materials using a salt spray chamber. Essential for quality control in coatings, metals, and finishes.