Our Valued Clients

Presto's Hot Tack Tester is an extremely effective testing machine which is used to perform hot tack test and check heat seal performance of laminated films, plastic films, and other packaging products.

.jpg)

TP310 is a prominent color measurement instruments used in many mainstream industries which have been designed and manufactured by competent engineers and scientists of Presto Stantest. The instrument has many advantages of other international standard color measurement instruments.

Punctures Testers are widely used to evaluate the rupture or puncture characteristics of a material. This is done by performing a compression test on a material, where the compression is done with the help of a probe...

The Presto grammage checking kit comprises of the GSM round cutter along with Digital weighing balance. GSM round cutter with imported industrial blades gives you a very accurate & seamless cutting of your samples.

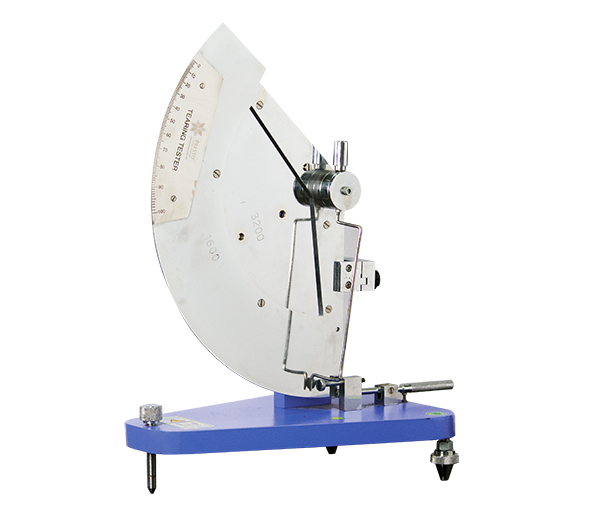

Tearing Strength Tester is a consistent tool useful to determine the tearing strength of fabrics, plastic films, and similar materials. Tearing Strength Tester is the tensile force required to rupture a pre-slit sample under controlled test conditions.

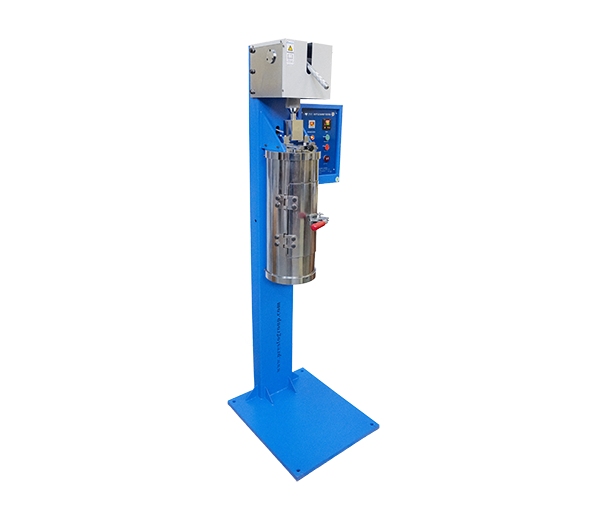

Presto Carbon Black Content Apparatus is commonly used for determining the Carbon Black content in polyethylene and polypropylene materials. The test is applicable only to samples where carbon is present in a free state.

Presto Carbon Black Dispersion Test Apparatus is mainly used for the determination of carbon black dispersion. It finds wide application in the plastic industry. The instrument comprises of a hot plate for sample placement.

.jpg)

The Farbung TP110 is a highly used and preferred color measurement instruments in many industries. There are several new features that are added to the product by the highly competent team of engineers and scientists of Presto Stantest.

Presto's Profile Projector is robust measuring testing equipment which is widely used in PET & Preform Industries, quality assurance departments, machine shops and also in industrial testing laboratories.

The Presto Ultra Low Temperature Deep Freezer is equipped with an air cooled compressor and CFC free refrigerators. These systems are installed to provide efficient cooling and consistent flow in the cabinet.

Environmental Stress Cracking Resistance Tester is a unique test cabinet designed to detect the change in the physical characteristics of the plastic material and to ascertain the actual working life of test samples at environmental stress.

Heat Sealer Prima is a consistent tool used to perform sealing on flexible packaging products and other thermoplastic materials using pressure and heat by maintaining high temperatures. A heat sealer is used to measure the heat seal performance of composite films.

Availability: In Stock

Shipping Area: Throughout the world

A Digital Bottle Burst Tester is used in PET bottle industries to test the strength of the bottles against bursting. For PET industries, it is important to provide best quality bottles to the bottling plants so that the best safety of the products could be ensured with proper quality testing.

Registered Design Patent No. 279110

Presto Adhesion Strength Tester is used to quantify the permanence of adhesion or peel ability of self- adhesive pressure sensitive materials. Peel adhesion is defined as the force required for removing a pressure sensitive coated material.

Peel Bond Strength Digital Tester is a standardized test machine, which is widely used to conduct accurate peel/seal strength test for adhesive materials. Suitable for measuring the stability of adhesives like tape or glue, it is a reliable quality control equipment. It is used for checking the ability of the sample to get peeled off from a surface. The testing equipment is designed and manufactured according to ASTM D903 standard.

Presto Peel Strength Tester has a display screen which is based on a hi-tech microprocessor that converts force applied into numeric values. So, the peel adhesive strength value that is measured can be directly viewed on the screen. Application force is controlled uniformly; this is done in order to ensure equal distribution of pressure, all over the test sample.

Registered Design No. 361206-003

Availability: In stock

Hot Air Oven is a unique test cabinet designed to detect the change in the physical characteristics of the material and to ascertain the actual working life of testing device at elevated temperature. Works on Forced air circulation, thermal convection principle, suitable for Tests like heat deformation, compression set, heat resistance required in rubber and plastic industries.

.png)

The Presto Dart Impact Tester is used for determining the impact of a free falling dart on a plastic film. The energy of the falling dart causes the film to fail under specified conditions. The dart has a hemispherical head and is held by a strong electromagnetic dart holder.

In stock

Magnamike, manufactured by Olympus, is a premium-quality device renowned for its excellence in conducting wall thickness gauge testing. Offering a non-destructive testing method, this instrument is ideal for measuring the wall thickness of PET bottles. Presto Stantest serves as an authorized dealer for this device.

In stock

The Tensile testing Machine is highly recommended for evaluating the tensile strength of products and materials. The equipment is based on the Constant Rate of Traverse (CRT) principle. It is equipped with an upper jaw and a lower jaw. Universal Tensile Testing Machine is a reliable piece of equipment which is widely used for checking tensile strength of a product/sample. One of the most common mechanical testing techniques used to determine tensile strength, this is a method wherein controlled tension is applied to a sample until it fully fails.

Thus, the material properties of the sample can be easily determined by this test. It involves measuring the force required to elongate a sample under test to breaking point. Using this test, manufacturers and quality managers are able to determine the core strength of their products.

Registered Design Patent No. 252611

Availability: In stock

The Presto Melt Flow Index Tester - NXG Model is a reliable instrument used for evaluating and analyzing the flow properties of molten plastics or resins. The determination of the melt flow index of plastic materials is an important parameter in the evaluation of its quality.

Presto Melt Flow Index Tester is used for evaluating the flow properties of molten plastics or resins. The Melt flow Index of thermoplastic materials is defined as the rate of flow (in grams per ten minutes) of extrudates of molten resins through a jet of a particular length and diameter.

Heat Deformation - HDT/VSP Tester is a consistent tool useful for determining the ability of a given polymer to bear load at elevated temperatures. Accurate and reliable deflection or deformation is an important component in the plastics industry.

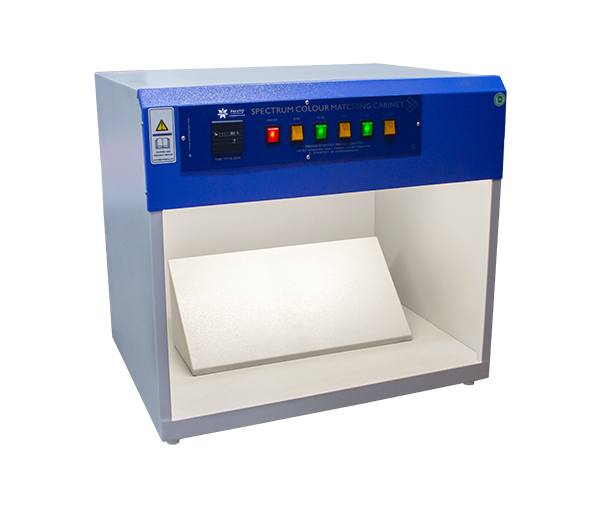

The Presto Color Matching Cabinet Spectrum Asia II is one of the widely used lab testing instrument in the industries and laboratories where it is important to maintain the color consistency of the products. This color matching machine will provide accurate assessment of colors under standardized environment for evaluation and visual assessment of colors.

Vibration simulation is an efficient and cost-effective way of determining damage caused by the repetitive movement in the vehicles. In just a few hours we can pinpoint potential damage areas in your package or product caused by vibration.

Our Vibration Table is customizable. You can get a Digital, Computerised, or touchscreen Vibration table according to your sample testing needs! Be it swivel, synchronous, or asynchronous, test your sample to its fullest to ensure durability, long life, and zero rejections.

Availability: In stock

Polyurethane elastomers are widely used in industries for making of different components. These components need to survive very harsh conditions where they have to face extensive forces and stress that can result into failure of the components. This is why the manufacturers need to ensure the best quality of the materials that is used for manufacturing of the components.