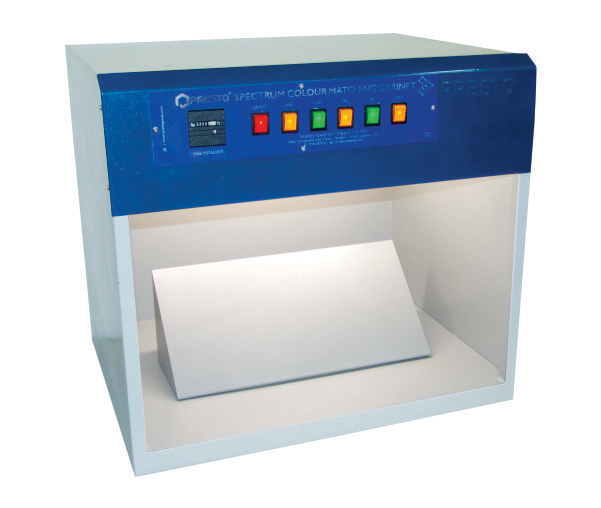

The colour industry cannot rely on their eyes for testing the colour consistency throughout the production batch under distinct lights. Human eyes cannot guarantee if the colour consistency is maintained or not and also if metamerism will cause an issue for the product. For detection of such colour defects, one must conduct standardized testing with Color matching box. The cabinet is used for numerous things, the user can see if the product colour is matching with the master colour shade and if it is the same throughout the production. It can also show the product colour under all possible lighting conditions which are used in the Asian continent. The lights which are fitted in the chamber are - Artificial Daylight, Triphosphor Fluorescent Light, Ultra Violet Black Light, Tungsten Filament Light, and Cool White Light. Also, there is a standard angular platform designed in the cabinet to place the specimen for testing under lights. The cabinet is made up of high-grade steel material which is plated with corrosion-resistant plating. Get Color Matching Cabinet in Pune with all the technical feature.

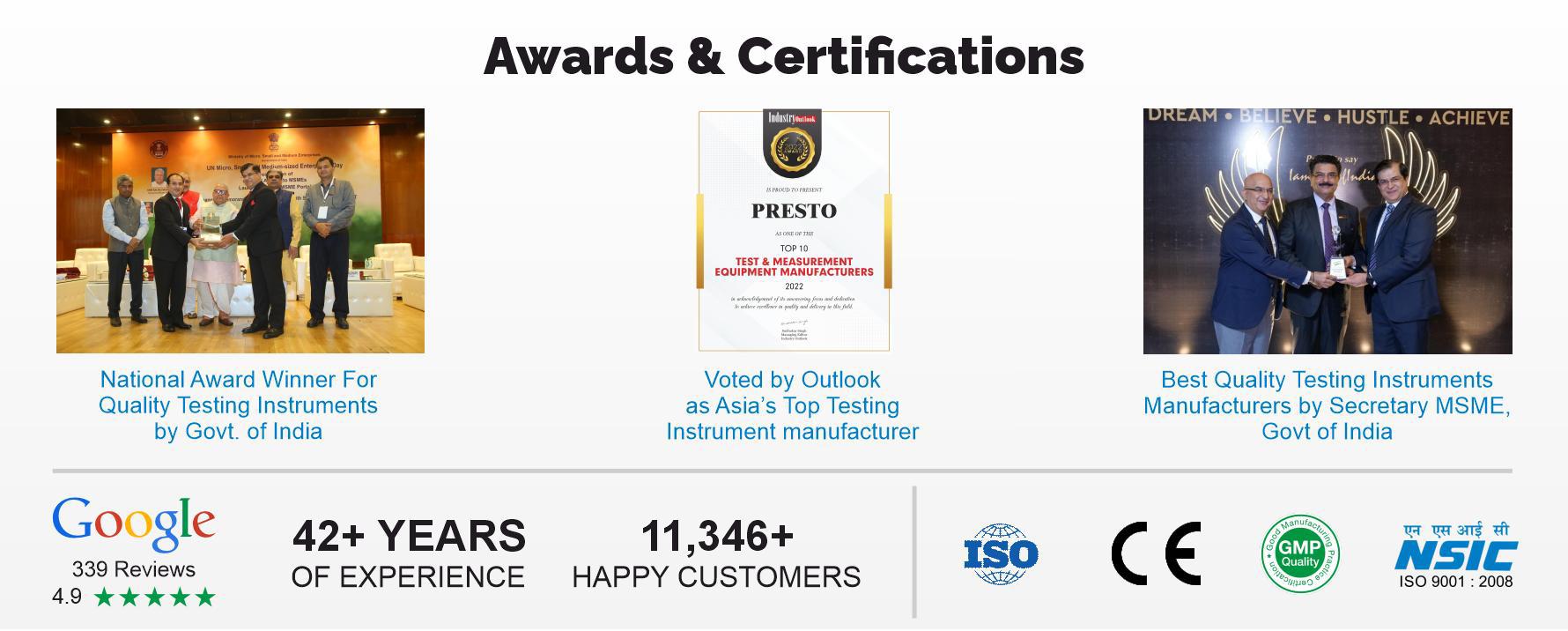

Trusting by the best, serving the best