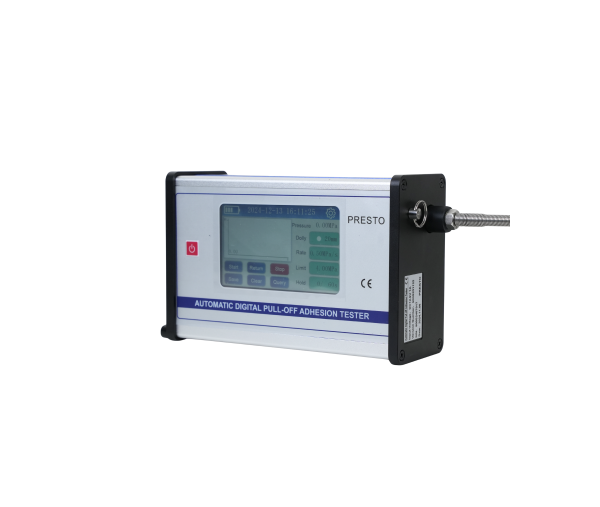

The Pull-Off Adhesion Tester from Presto Group is built for people who need clean and steady readings of how well a coating sticks to a surface. It uses the pull-off method to test the bonding strength of paint layers, protective films, and surface treatments on many types of materials. This makes it useful for coating makers, inspection teams, and anyone who wants clear numbers before they send a product to market.

A pull-off adhesion tester checks how firmly a coating holds on to a surface. It works by attaching a metal dolly to the coated area and pulling it straight up till the coating comes off or breaks. The force needed to lift the dolly shows the bond strength.

People use this test in places like construction sites, auto workshops, and factory units where coating strength is checked every day. It shows if the surface was set up the right way before the layer was applied, and if that layer will stay firm once the product is out in the real world. The method follows global rules, so the readings stay clear and easy for lab teams and field staff to work with.

Pull-Off Adhesion Tester Application

A pull-off adhesion tester checks how firmly a coating holds on to a surface. It works by attaching a metal dolly to the coated area and pulling it straight up till the coating comes off or breaks. The force needed to lift the dolly shows the bond strength.

People use this test in places like construction sites, auto workshops, and factory units where coating strength is checked every day. It shows if the surface was set up the right way before the layer was applied, and if that layer will stay firm once the product is out in the real world. The method follows global rules, so the readings stay clear and easy for lab teams and field staff to work with.

Pull-Off Adhesion Tester Working Model

This helps users understand if the coating failed within its own layer, between the layer and the substrate, or inside the base material. These details help teams correct mistakes in surface cleaning, application, or material choice.

Pull-Off Adhesion Tester: Pros.

Main plus points

Use a Pull-Off Adhesion Tester

Strong bonding keeps coatings from lifting, peeling, or cracking early. A weak bond can lead to rust, water entry, or surface damage. The pull-off tester helps you check whether your surface cleaning and coating steps are done the right way. It also helps inspectors catch bonding problems before they turn into customer complaints.

It is helpful because it:

Presto Group is a well-known maker of pull-off adhesion testers in India. Reach out for a quote.

Accessories Included

Trusting by the best, serving the best