- /

- Blog / Achieve Superior Product Quality Through Smart Drop Testing Strategies

Achieve Superior Product Quality Through Smart Drop Testing Strategies

Picture this: a customer eagerly unboxes their brand-new gadget, only to find it cracked because it couldn’t survive a minor tumble during shipping. Ouch. That’s a return, a bad review, and a hit to your brand’s reputation. In today’s cutthroat market, delivering top-notch product quality isn’t just a goal—it’s a must. One of the smartest ways to ensure your products can take a beating and still perform? Drop testing. By mimicking real-world mishaps, like a phone slipping from a pocket or a package bouncing off a delivery truck, you can catch weaknesses early, beef up your drop test packaging, and keep customers smiling. Let’s dive into how drop testing strategies, powered by tools like the Drop Tester and standards like ASTM D5276 Free Fall Drop Testing, can make your products tougher than ever.

Why Drop Testing is a Game-Changer

So, what’s drop testing all about? It’s a quality control process where you intentionally drop products or their packaging to see how they hold up. Think of it as a stress test for real-life clumsiness or rough handling. Whether it’s a laptop jostled in a warehouse or a fragile vase shipped across the country, drops happen. And when they do, your product needs to come out unscathed. That’s where a solid drop test procedure for packaging comes in, helping you spot flaws before they become customer complaints.

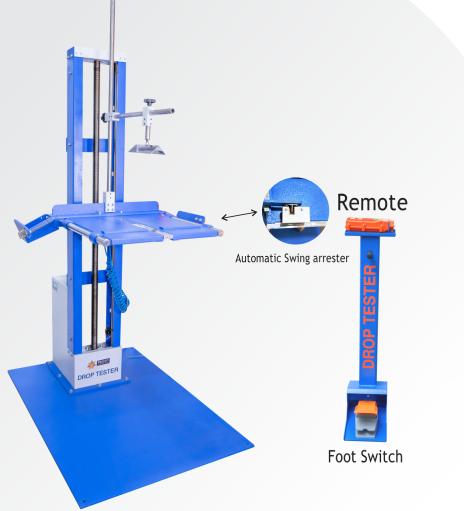

The stakes are high. A single failure can lead to costly returns, angry customers, or even safety issues. But with the right Drop Testing Equipment, like a Zero Altitude Drop Tester, you can simulate everything from minor bumps to major falls, ensuring your products are ready for the real world. Plus, drop testing isn’t just about durability—it’s about building trust, cutting down on warranty claims, and meeting industry standards.

The Power of Drop Testing Equipment

At the core of any great drop testing plan is Drop Testing Equipment. These machines are like the gym for your products, putting them through controlled drops to test their strength. A Drop Tester lets you adjust drop heights and angles, and surfaces to mimic scenarios like a package sliding off a conveyor belt or a product dropped during unboxing. Want to test what happens when a box hits the ground at a weird angle? The Drop Tester has you covered.

For products that face low-height drops—like electronics handled during shipping—a Zero Altitude Drops Tester is a lifesaver. It’s designed to simulate those sneaky, smaller impacts that can still cause big damage. With the right Drop Testing Equipment, you get hard data on what breaks, what bends, and what survives, so you can tweak your designs or upgrade your drop test packaging before it’s too late.

A Quick Look at Drop Testing Essentials

To give you a clearer picture, here’s a table summarizing the key components of drop testing:

| Aspect | Details |

| Equipment | Drop Tester, Zero Altitude Drop Tester, other Drop Testing Equipment for controlled drops. |

| Standards | ASTM D5276 Free Fall Drop Testing for packaging and product durability. |

| Key Process | Drop test procedure for packaging to simulate real-world impacts. |

| Benefits | Improved drop test packaging, fewer returns, compliance, customer trust. |

.jpg)

Improved drop test packaging, fewer returns, compliance, customer trust.

This table highlights why investing in the right tools and processes is crucial for product quality.

Crafting a Bulletproof Drop Test Procedure for Packaging

A killer drop test procedure for packaging is your roadmap to consistent, reliable results. Here’s how to nail it:

- Set Your Goals: Are you testing the product itself, the packaging, or both? Do you need to meet standards like ASTM D5276 Free Fall Drop Testing, or are you just making sure your product survives a single drop?

- Pick Your Parameters: Choose drop heights, angles, and surfaces based on real-world risks. A package dropped from a forklift needs a different test than one mishandled by a delivery driver.

- Prep Your Samples: Use actual products or prototypes, packed exactly as they’ll be shipped. No shortcuts here—realistic packaging is key.

- Run the Test: Fire up your Drop Tester and let it rip. Follow the sequence laid out in standards like ASTM D5276 for a thorough, repeatable process.

- Check the Damage: After each drop, inspect the product and packaging. Cracks? Dents? Log everything to pinpoint weak spots.

- Rinse and Repeat: Use what you learn to improve your product or packaging, then test again until you’re confident it’s rock-solid.

This structured approach ensures your drop test procedure for packaging catches issues early, saving you from costly fixes down the line.

Decoding ASTM D5276 Free Fall Drop Testing

If you’re in industries like electronics, medical devices, or consumer goods, you’ve probably heard of ASTM D5276 Free Fall Drop Testing. This gold-standard guideline spells out how to test shipping containers and packaged products by dropping them in a controlled, free-fall setup. It’s all about making sure your packaging can handle the rough-and-tumble of real-world shipping.

ASTM D5276 covers:

- Drop Heights: Different heights based on your product’s weight and use case.

- Test Sequences: Multiple drops from various angles to mimic all sorts of impacts.

- Pass/Fail Criteria: Clear rules for what counts as a successful test.

Following ASTM D5276 Free Fall Drop Testing not only ensures your products are tough but also proves they meet global standards, giving you a leg up with retailers and customers.

Supercharging Your Drop Test Packaging

Your product might be tough, but without great drop test packaging, it’s vulnerable. Packaging is your product’s armor, soaking up shock and keeping everything safe. Smart drop testing helps you design packaging that’s up to the task.

Here’s how to level up your drop test packaging:

- Choose Smart Materials- Go for options like corrugated cardboard, foam inserts, or air pillows that cushion without adding bulk.

- Design for Impact- Build in features like reinforced corners or shock-absorbing zones to spread out impact forces.

- Test Like Crazy:- Use a Drop Tester to try different packaging setups and find the one that works best.

Take a company shipping delicate glassware. By using a Zero Altitude Drop Tester to simulate short drops during transport, they might find that a mix of foam padding and sturdy cardboard cuts breakage rates in half. That’s the power of testing.

Why Smart Drop Testing Pays Off

Investing in drop testing isn’t just about avoiding disasters—it’s about building a better business. Here’s what you gain:

- Top-Tier Quality:- Catch and fix design flaws before they reach customers.

- Lower Costs:- Fewer returns, repairs, and warranty claims mean more money in your pocket.

- Happy Customers:- Durable products build loyalty and trust.

- Compliance:- Meet standards like ASTM D5276 to stay market-ready.

Plus, every test gives you data to make your products and processes better, creating a cycle of constant improvement.

Picking the Perfect Drop Tester

Not all Drop Testers are created equal. The right one depends on your products and goals. A Zero Altitude Drop Tester is great for lightweight items like electronics, while heavier goods might need a beefier machine for high-impact tests.

When shopping for Drop Testing Equipment, ask:

- Is it versatile? Can it handle different heights, angles, and surfaces?

- Is it precise? You need accurate, repeatable results.

- Is it user-friendly? Look for equipment that fits smoothly into your workflow.

The right Drop Tester makes testing faster, easier, and more reliable.

Frequently Asked Questions About Drop Testing

Here are answers to some common questions about drop testing:

Q1. What is the purpose of drop testing?

Ans. Drop testing evaluates how well a product or its packaging withstands impacts from drops, ensuring durability, safety, and compliance with standards like ASTM D5276 Free Fall Drop Testing.

Q2. How does a Zero Altitude Drop Tester differ from other drop testers?

Ans. A Zero Altitude Drop Tester is designed for low-height drops, ideal for simulating minor impacts during handling or shipping, unlike standard Drop Testers that handle a wider range of heights.

Q3. Why is ASTM D5276 important for packaging?

Ans. ASTM D5276 Free Fall Drop Testing provides a standardized method to test packaging durability, ensuring it can protect products during shipping and meet global industry requirements.

Q4. How can I improve my drop test packaging?

Ans. Optimize drop test packaging by using shock-absorbing materials (e.g., foam, air cushions), designing for impact resistance, and testing multiple configurations with a Drop Tester to find the best solution.

Wrap-Up: Build Better Products with Drop Testing

In a world where quality is king, drop testing Machine is your secret weapon. By using tools like the Drop Tester, following standards like ASTM D5276 Free Fall Drop Testing, and perfecting your drop test packaging, you can create products that laugh in the face of gravity. A solid drop test procedure for packaging catches problems early, saves money, and keeps customers coming back.

Don’t roll the dice on quality. Get serious about Drop Testing Equipment, test smart, and make durability your brand’s calling card. Your products—and your customers—will thank you.

Secure Every Shipment.

Know the Drop Tester Price that fits your business—contact our experts today.

Mail: info@prestogroup.com | Phone: +91 9210 903 903

Recent Blogs

- Compression Testing Machine Operating Method & Packaging Strength Testing Applications

- Bottle Cap Torque Tester Digital Torque Testing for Packaging Quality Control

- Controlled Humidity Chamber: Environmental Testing Methods, Applications & Packaging Testing Use Cases

- Spectrophotometer & Portable Spectrophotometer: Working Principle and Laboratory Applications

- Paint Tester & Coating Testing Equipment: Types, Testing Process, and Industrial Applications