- /

- Blog / Dry Heat Sterilization: How It Works, Key Advantages, and Formula

Dry Heat Sterilization: How It Works, Key Advantages, and Formula

Sterilization is one of the most important processes in the laboratories, clinics and industries when complete microbial inactivation is mandatory. From the innumerable techniques employed, dry heat is one of the oldest and time-honoured methods with hot air oven or special purpose designed dry heat sterilizer being used most widely. Contrary to steam sterilization (moist heat), which works with the presence of humidity, and is commonly performed in autoclave using steam as sterilizing agent, low-temperature dry heat achieves microbial death, spore killing, and destruction of pyrogens at high temperatures without moisture.

This post discuss the fundamentals, temperature range, types of equipment diagram, advantages, limitations and formulas of dry heat sterilization.

Principles of Dry Heat Sterilization

The principle of dry heat sterilization is oxidative destruction. The process relies on hot air circulating inside a closed chamber, where continuous exposure at high temperatures causes:

- Denaturation and coagulation of proteins.

- Oxidation of cellular constituents.

- Irreversible dehydration of microbial cells.

Unlike moist heat, which penetrates organisms quickly through condensation, dry heat works more slowly but delivers highly stable sterilization, particularly suited for materials that cannot tolerate moisture or steam.

Equipment: Hot Air Oven and Dry Heat Sterilizer

1. Hot Air Oven

The hot air oven is the classical instrument for dry heat sterilization. It consists of:

- Double-walled chamber:- The outer wall is insulated to retain heat.

- Heating coils:- Typically placed around the chamber to provide uniform heating.

- Fan/blower:- Ensures air circulation for even distribution of temperature.

- Thermostat/digital controller:- Maintains set sterilization temperature.

- Shelves:- For placing instruments such as glassware, powders, and metal tools.

2. Modern Dry Heat Sterilizer

Modern dry heat sterilizers are advanced ovens with programmable logic controllers (PLC), digital temperature readouts, validation ports, and safety alarms. Some are designed with high-efficiency particulate air (HEPA) filters to prevent contamination during loading and unloading.

Dry Heat Sterilizer Temperature

The sterilization efficiency directly depends on temperature and exposure time. Below are the commonly standardized conditions:

- 160°C for 120 minutes (2 hours)

- 170°C for 60 minutes (1 hour)

- 180°C for 30 minutes

- 190°C for 12 minutes (for rapid sterilization cycles)

These parameters are validated by international standards such as USP, BP, and ISO sterilization guidelines.

The temperature must be carefully monitored, as insufficient exposure may leave viable spores, while excessive heating may damage sensitive materials.

Dry Heat Sterilizer Diagram

A typical dry heat sterilizer diagram includes:

- Insulated Outer Body – prevents heat loss.

- Inner Chamber – where materials are placed.

- Heating Elements – electric coils providing thermal energy.

- Air Circulation Fan – ensures uniform heat distribution.

- Thermostatic/Digital Control Panel – to regulate and display temperature.

- Exhaust Vent – removes burnt particles or unwanted fumes.

Such a layout ensures that sterilization is homogeneous, controlled, and safe for critical materials.

Metrics and Formula for Dry Heat Sterilization

Sterilization effectiveness is often measured in terms of D-value, Z-value, and F-value, which quantify microbial inactivation kinetics.

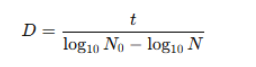

1. D-Value (Decimal Reduction Time)

Definition: The time required at a given temperature to reduce microbial population by 90% (1 log cycle).

Formula:

Where:

- ttt = exposure time (minutes)

- N0N_0N0 = initial microbial count

- NNN = surviving microbial count

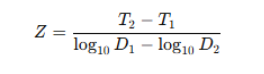

2. Z-Value

Definition: The temperature increase required to reduce the D-value by 90%.

Formula:

This value indicates the thermal resistance of microorganisms.

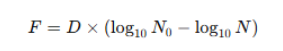

3. F-Value (Lethality Value)

Definition: The equivalent time at a reference temperature (commonly 170°C for dry heat) required to achieve sterilization.

Formula:

These metrics are indispensable for validation and qualification of sterilization cycles in pharmaceutical and medical industries.

Advantages of Dry Heat Sterilization

- Moisture-Free Method

Ideal for sterilizing substances sensitive to moisture such as oils, powders, and metallic instruments. - Non-Corrosive

Unlike steam sterilization, dry heat does not corrode surgical instruments or carbon steel. - Efficient for Glassware

Ensures sterilization of Petri dishes, flasks, pipettes, and test tubes without structural deformation. - Destroys Pyrogens

High dry heat can destroy endotoxins (pyrogens), which is crucial for pharmaceutical glassware sterilization. - Simple and Cost-Effective

Hot air ovens are relatively inexpensive, easy to maintain, and operate with standard electricity.

Limitations of Dry Heat Sterilization

- Longer Exposure Time

Requires significantly more time than moist heat sterilization to achieve the same microbial kill. - High Energy Consumption

Continuous heating to 160–180°C consumes more power compared to steam sterilization. - Limited Material Compatibility

Plastic items, rubber goods, and heat-sensitive substances cannot withstand such high temperatures. - Slow Penetration

Heat penetration is slower compared to moist heat, making cycle design more challenging for dense materials. - Validation Requirement

Every load must be validated with thermocouples and biological indicators to ensure sterilization integrity.

Applications of Dry Heat Sterilization

- Pharmaceutical Industry – sterilizing glass ampoules, vials, and stoppers.

- Clinical Laboratories – sterilizing glassware, surgical scissors, and forceps.

- Food Industry – eliminating microbial contamination in powders and oils.

- Research Institutions – for sterilizing instruments where moisture is undesirable.

Presto Group: Leaders in Dry Heat Sterilization Equipment

For laboratories and industrial sectors striving for dependable and efficacious dry heat sterilizers and hot air ovens, the Presto Group has ascended as a venerable manufacturer. With decades of accrued expertise, Presto Group is devoted to engineering premium sterilization apparatus tailored for pharmaceuticals, research laboratories, and healthcare establishments.

Salient Features of Presto Group Instruments:

Precise Thermal Regulation- Sophisticated digital controllers facilitate consistent sterilization cycles, mitigating the risk of thermal deviations.

- Homogeneous Heat Dispersion- Cutting-edge air circulation mechanisms assure uniform sterilization throughout the chamber.

- Robust Fabrication- Corrosion-resistant stainless steel interiors bolster durability and prolong operational lifespan.

- Standards Compliance- All apparatus conform to ISO, CE, and GMP stipulations, rendering them suitable for rigorous laboratory and industrial applications.

- Intuitive Operation- User-centric interfaces allow effortless programming and real-time monitoring, ensuring secure and efficient utilization.

Through providing highly customizable configurations, Presto Group adeptly accommodates diverse industrial and laboratory requisites, thereby rendering dry heat sterilization markedly safer, expeditious, and efficacious.

Closing Remarks

Dry heat sterilization , using hot air oven or advanced sterilizers, destroys microbes via high temperature oxidation. It is ideal for moisture free, cost efficient sterilization and pyrogen elimination. Though slower and unsuitable for heat-sensitive items, applying D-, Z-, and F-value calculations ensures validated, safe cycles, making it a reliable method in labs, hospitals, and industries.

Ready To Purchase Your Hot Air Oven Or Dry Heat Sterilizer?

Need a dependable dry heat sterilizer or hot air oven for your lab, hospital or R&D facility? Presto Group – Sterilizers You Can Trust at a Price You’ll Love Favoured by Hospitals and Pharmacies, Among Others!

-

- Call now: +91 9210 903 903

- Email: info@prestogroup.com

Our experts can help you decide which product is best for your specific application and will quote you pricing, handsome installation options, and even support you in validating the performance. Never settle for less than actual sterilization – buy precision and safety now!

Recent Blogs

- Controlled Humidity Chamber: Environmental Testing Methods, Applications & Packaging Testing Use Cases

- Spectrophotometer & Portable Spectrophotometer: Working Principle and Laboratory Applications

- Paint Tester & Coating Testing Equipment: Types, Testing Process, and Industrial Applications

- Moisture Meter: Types, Working Principle & Applications in Industrial Labs

- Environmental,Pharmaceutical, and Research Laboratories in BOD Incubator