- /

- Blog / Moisture Meter: Types, Working Principle & Applications in Industrial Labs

Moisture Meter: Types, Working Principle & Applications in Industrial Labs

Moisture content impacts product quality, shelf life, strength, and compliance in many industries. With a moisture meter, industrial labs can measure how much water is in solids, pulses, grains, paper, wood, chemicals, etc. Laboratories use these readings for incoming inspection, in-process checks, and final release testing. Various types of meters suit different materials, moisture ranges, and accuracy requirements. Some are quick screening tools, others are reference methods for reporting/audits. This guide describes the main moisture meter types, how they work, and where industrial labs use them. It keeps the concepts simple but covers key technical points encountered in real testing workflows.

Moisture Meter: The Purpose And Role Of The Industrial Lab

The moisture meter in industrial labs controls variation and reduces batch failures. Moisture changes in storage, mixing, drying, or transport, so labs test it at several stages. Results help you accept a raw lot, adjust a dryer, or release a finished batch. In regulated environments, moisture data is also used for documentation, traceability, and investigation of results outside of specification.

Another reason labs use moisture testing is comparability. A single material may have different moisture readings based on the method used; labs must match that method with the material and reporting requirement. For routine checks, speed and repeatability are important. For dispute resolution, a recognised reference method matters.

Moisture testing may report water as:

- Total moisture (water plus other volatile loss in some methods)

- Free moisture on the surface

- Bound moisture trapped in the structure or crystal form

Common Lab Quality Benchmarks

Laboratories typically require moisture testing for the following applications:

- Product specification limits

- Process set points for drying or blending

- Packaging and storage stability targets

- Customer or internal acceptance criteria

Types Of Moisture Meter Used In Industrial Labs

Industrial labs typically choose between rapid meters and reference-grade instruments. Rapid meters are ideal for quick decision-making on the floor. Reference methods ensure precise reporting, especially when customers or audits expect traceable results. Many labs keep both, using one for screening and one for confirmation.

Pin Type Resistance Moisture Meter

This type uses two pins that penetrate the material. It measures electrical resistance, which changes with moisture. It is common for wood, paper stacks, and some building materials.

Pinless Capacitance Moisture Meter

This type sits on the surface and measures dielectric properties. It is non-destructive and faster for scanning larger areas like panels and rolls. The depth of measurement depends on the sensor design and the density of the material.

Halogen Moisture Analyzer (Loss On Drying)

The halogen moisture tester applies heat on the sample and observes the change in weight. It reports moisture based on mass change. It is widely used for powders, foods, chemicals, and plastics, but it can also lose non-water volatiles if they evaporate at the test temperature.

Karl Fischer Titration Moisture Meter

Karl Fischer measures water by a chemical reaction. It is highly specific to water and works well for low moisture levels. Labs use it for pharmaceuticals, oils, solvents, and polymers where accurate low-level moisture matters.

Infrared And Microwave Moisture Meter

Infrared and microwave systems often support online or at-line checks. Microwave methods can penetrate deeper and read bulk moisture, useful for thicker materials. These systems need good calibration against lab reference methods.

Working Principle: How Moisture Meter Methods Measure Water

Each moisture meter method alters the physical or chemical change in the moisture value. Knowledge of the working principle is critical for avoiding false readings and simplifies the overall process. Industrial labs document this in SOPs so operators know what can affect results. It also helps if the results differ between the two ways.

Practically, labs control variables such as sample preparation, temperature, time, and instrument calibration. They also define acceptance criteria for repeat tests and when confirmation methods should be used. Good practice is to run checks with known standards/control samples.

Electrical Resistance Principle

Higher moisture usually lowers resistance. The meter converts resistance into moisture percentage using a calibration curve. Contact pressure, temperature, and material chemistry can change conductivity, so calibration is critical. (H3)Capacitance Principle

Loss On Drying Principle

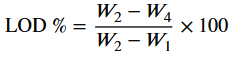

The instrument weighs the sample, heats it, and weighs it again until an endpoint rule is met. Moisture percent is commonly calculated as:

![]()

Where is the initial mass, and is the final mass after drying?

With weighing bottle weights:

Where w1 is the weight of the empty bottle, w2 weight of the bottle and sample(before drying), and w4 weight of bottleand and sample (after drying)

Karl Fischer Principle

Water reacts with Karl Fischer reagents, and the titration endpoint indicates the amount of water. It can be run volumetrically for higher water content or coulometrically for trace water. Sample handling matters because ambient humidity can add error.

Key Factors That Change Readings

- Sample temperature and ambient humidity

- Particle size, mixing uniformity, and sample mass

- Heating temperature and time profile in drying methods

- Chemical components that evaporate or react during testing

- Calibration curve validity and instrument drift

Applications In Industrial Labs And Selection Criteria

Industrial labs apply moisture meters for the evaluation of a wide variety of raw materials, process controls, and quality testing of finished products. The same lab may run different methods for different products. A fast method keeps production moving. A specific method supports accurate release testing. Selection is usually documented with method justification and verification data.

Labs also link moisture results to process actions. For example, a dryer setting change may require a moisture confirmation check. Packaging lines may use moisture checks to reduce spoilage or caking. When a complaint occurs, moisture history often becomes part of the investigation record.

Practical Selection Criteria In Labs

- Moisture range needed, for example, trace water versus high moisture

- Specificity to water versus total volatile loss

- Sample type and destruction allowed

- Speed, throughput, and operator skill level

- Calibration and traceability requirements

Wrapping Up

A moisture meter plays a critical role in an industrial setting as moisture drives quality, stability, and process control. Resistance and capacitance meters support quick checks, while loss on drying and the Karl Fischer method provide accurate reporting when precision and clarity matter. The test results are more appropriate when they come from industrial labs matching the method to the material, controlling sample handling, and maintaining calibration with routine checks. With clear SOPs and appropriate instrument selection, moisture testing is faster, more consistent, and easier to defend during audits.

Contact Presto Group Today!

Get rid of hidden moisture resulting in defects and damage. Invest in moisture testing devices maintain consistent standards and customer satisfaction.

Call us: +91 9210903903

Email: info@prestogroup.com

Visit: www.prestogroup.com

Address: Plot No. I, 42, NH-19, Block C, DLF Industrial Area, Sector 32, Faridabad, Haryana 121003

Recent Blogs

- Moisture Meter: Types, Working Principle & Applications in Industrial Labs

- Environmental,Pharmaceutical, and Research Laboratories in BOD Incubator

- Vibration Tables Testing in Automotive and Aerospace Component

- Digital BS Testing Machines Features, Benefits, and Advantages

- Ways how TAPPI T811 ECT Tester Prevents Packaging Failure