Think of the time when a newly constructed bridge is opened, or a new engine part is put under extreme stress. In each engineering situation, materials need to be shown they can withstand the load—the stretching, straining, and pulling forces they will be subjected to. Without demonstration, collapse is inevitable, and the results vary from minor inconvenience to disaster.

The tensile test is the industry standard technique used to obtain this valuable evidence. It's a straightforward concept with deep meaning: pull something until it fails, and record all that occurs in between. Learning to execute the tensile test process step-by-step is paramount to engineers to build their Expertise, Authoritativeness, and Trustworthiness in the field of material science.

This handbook discusses the basis and procedures of this fundamental test in various material forms.

The tensile test is a central mechanical test in which a specimen of material (a "dog bone" or "dumbbell" shaped sample) is subjected to a controlled, continuously increasing axial tensile force to failure (fracture). Data produced—plotted on a stress-strain curve—provides a material's underlying characteristics.

Conducting the test requires precision and attention to specification for compliance with global standards at international level such as ASTM D638 tensile test for plastics or ASTM E8 for metals.

The test specimen should be fabricated using exact sizes defined by the applicable standard. As an example, plastic specimens should conform exactly to the sizes which are indicated in ASTM D638. Having proper preparation is important because flaws in the specimen may lead to premature failure of the specimen and more importantly, incorrect measurement.

Careful alignment is essential to avoid bending or non-uniform stress by ensuring pure axial application of force. An extensometer is mounted on the gauge section of the sample to get accurate measurement of the very small changes in length (elongation) during the test.

The device is started and the grips separate at the desired speed (strain rate).

The test is carried out until material failure (it has reached the ultimate tensile strength test value). The ensuing data is charted as a stress-strain curve, from which engineers can determine the yield strength and tensile elongation in tensile testing, making comparisons among various alloys or polymer systems.

Although the process is equivalent, result interpretation varies extensively depending on the material in question:

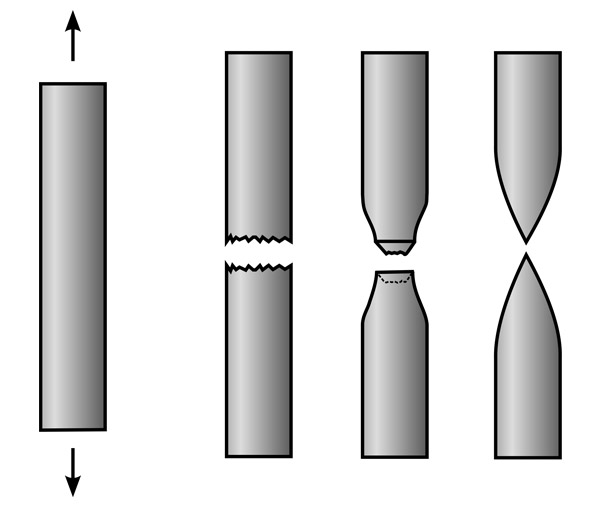

The tensile testing of metals, plastics, and polymers are often associated most with metals (i.e., steel or aluminum). Metals tend to exhibit a distinguishable and sharp yield point. This is characterized by an initial uniform elongation, followed by necking (a local reduction in area) before fracture. This information is used by engineers to guarantee structural elements achieve particular safety factors.

Plastics and polymers respond differently to testing. For example, ASTM D638 tensile test for plastics, which is common tests, is conducted differently. Plastics do not possess a distinct yield point, and the stress-strain curve is extremely a function of temperature and strain rate. Their characteristics, like high elongation, become most important in applications such as medical tubing or packaging film.

There are specialized machines, like a Digital tensile strength tester for rubber and textiles, that are applied for highly elastic products. For rubber, high elongation and tear resistance are more of an interest than a hard yield strength.

There is frequent confusion with the Difference between tensile test and compression test. Even though they both employ a UTM, they are opposites:

Tensile Test: Drags the material apart; tests strength against pulling.

Compression Test: Drives the material together; tests strength against crushing or buckling.

Concrete is strong in compression but not in tension, which is why the tensile test is the more general measure of basic material integrity.

A business manufacturing disposable surgical instruments required to confirm a new polymer utilized in a flexible section. One point of failure in this component could injure a patient. They needed evidence that the polymer would be able to withstand a minimum amount of pulling pressure without deforming permanently or breaking.

The Solution: They bought a high-precision Digital tensile strength tester for rubber and fabrics that could handle the fragile polymer film. Though the cost of the specialized unit was higher in terms of the Tensile test machine price, the investment proved to be worthwhile. By strictly adhering to the Tensile test procedure step by step as per ASTM D638, they obtained information on ultimate tensile strength test and yield strength and elongation in tensile testing. This information not only ensured patient safety but also established Authoritativeness and Trustworthiness among the regulatory agencies and hospital procurement officers.

If you are an Indian manufacturer in a high-growth industry, choosing the proper Tensile test equipment manufacturer in India or abroad is the key to assured product quality and long-term success.

The tensile test of metals, plastics, and polymers is the essential cornerstone of material science and engineering. Through precise measurement of yield strength and elongation in tensile testing, producers develop the expertise necessary to commit products that will not fail under load.

Ready to put your materials to the ultimate strength test? Contact a qualified Tensile test equipment producer today to discover the ideal Digital tensile strength tester for your quality control.

![]() Looking for the best tensile strength tester price? Contact Presto Group, the world’s leading manufacturer and supplier of high-quality tensile testing machines. Call +91 9210 903 903 or email info@prestogroup.com today for expert assistance and quotes!

Looking for the best tensile strength tester price? Contact Presto Group, the world’s leading manufacturer and supplier of high-quality tensile testing machines. Call +91 9210 903 903 or email info@prestogroup.com today for expert assistance and quotes!