- /

- Blog / What Is a Polariscope? Working, Usage & Benefits in Manufacturing

What Is a Polariscope? Working, Usage & Benefits in Manufacturing

Suppose you are a manufacturer of pet products, glass, or plastic products. You always claim that your products are always flawless. They could never have any kind of strain, crack, or defect that could compromise the product. These bold claims build trust among clients. But you know one dark truth. Behind all these claims, there is no QC. So, if something bad happens, you lose your customers, and your opponents win the game. So that you don’t lose out on your market share and vanish from the market, leading industrial instrument manufacturers like the Presto Group provide polariscope to run quality checks on your products, to make them flawless in a practical sense.

What Is A Polariscope?

A Polariscope is a specialised optical instrument that detects and analyses internal stresses in transparent materials such as glass, plastic, and crystals. There are usually lots of stress patterns in these products that our naked eyes cannot see. However, polarised light in the polariscope stress analyser reveals those stress patterns, helping manufacturers ensure better quality and safety. Whether used for glass inspection, plastic testing, or PET preform analysis, it plays a vital role in modern quality control.

What Is the Polariscope Working Principle?

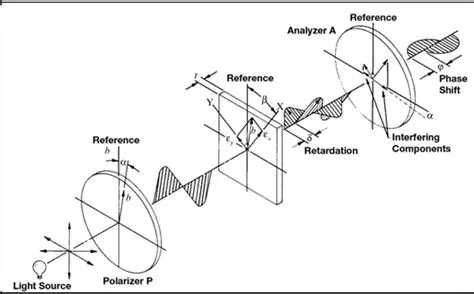

So, the polariscope working principle is to detect the cracks or defects in PET or glass products. Similar to a microscope, polariscope stress analysis machine incorporates a polarised light, which vibrates in a single plane. Some transparent materials, like glass or plastic, change the way light passes through them if they are under stress. This effect is called birefringence. When light passes through such a stressed material, it splits into two beams that move at slightly different speeds.

This machine has two special filters, called polariser, a.k.a. the light source, and analyser, the one where you look through. When the stressed material is placed between these filters, the two light beams mix together again and create colourful patterns, called fringes. These colours show where the material is under stress.

What Are the Primary Polariscope Uses in Manufacturing?

There are multiple industries where the polariscope uses are a must. Whether your business revolves around manufacturing PET & plastic products or goods made of glass, carrying out polariscope stress analysis is necessary to provide the perfect product to your clients. In manufacturing, the following are the primary polariscope uses:

- Detect Internal Stress – Identify flaws invisible to the naked eye.

- Enhance Product Quality – Make sure products meet safety and performance standards.

- Improve Production Processes – Adjust moulding, cooling, or annealing techniques.

- Support Education & Research – Demonstrate stress patterns in optical and material science studies.

- Crystal and Gemstone Testing – In the gemstone and synthetic crystal industry, polariscopes are used to distinguish between natural and synthetic stones, check for internal strain, and identify crystal orientations. This ensures authenticity and quality in jewelry and precision instruments.

Is polariscope working principle only for QC? Not exactly. While running a thorough quality check, performing this is necessary, it also lowers costs by a high margin as there will be no recall, rework, while building trust among the clients.

How Is a Polariscope for Glass Used in Quality Control?

A polariscope for glass is one of the most common applications in manufacturing. Glass can develop internal stresses during cooling or forming processes, which may not be visible but have a high chance of cracking or shattering later.

By placing the glass sample between the polarising filters and observing the fringe patterns, the quality checkers can determine whether the glass has been toughened properly or not. This is especially important for products like safety glass, optical lenses, and glass containers, where structural integrity is a must.

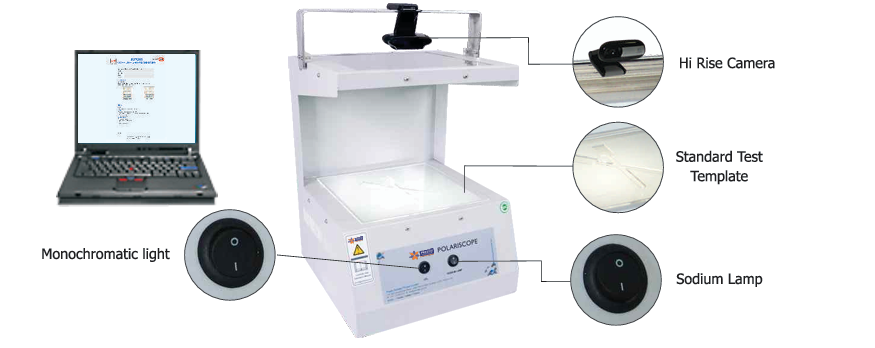

These are some of the features of the Pestro polariscope for glass:

- Highly reliable Monochromatic light source for visualisation

- It can be tilted through 180° and clamped in any position.

- It has a 190mm diameter field of view

- The working space of Polariscope can be adjusted easily between 290mm and 440mm.

How Does a Polariscope Strain Viewer Help in Industry?

These are some of the features of a polariscope stain viewer:

- 7-inch touch screen with 260 X 240 mm viewing area

- Monochromatic CFL light & cSodium lamp

- 45° and 90° measuring angle

- Test Report includes Reason for Defect Along With Suggested Action

- Easy Data Management. Users can create product identification, company, and check by details

- Inbuilt hardware & PLC software

- Mild steel material

All these features quickly reveal stress patterns in materials. It is widely used on production floors for quality inspection of transparent products. In the industrial arena, the strain viewer provides immediate feedback, allowing manufacturers to make quick adjustments to processes like heating, cooling, or pressure application. For example, in bottle manufacturing, the polariscope strain viewer measures even wall thickness and proper stress distribution to prevent breakage during use.

Why Is a Polariscope for Plastic Inspection Important?

With a valuation of around ₹4 billion in 2024, the plastic industry contributed around 0.5% of India's GDP. In 2023 alone, India consumed around 22 million tonnes of plastic. There is probably a handful of industries that don't require plastics to produce or run a business. So, making sure the plastics used by the customers and other manufacturers are not faulty is crucial.

There comes into play the polariscope for plastic. It detects internal stresses formed during injection moulding or extrusion. Plastics often undergo uneven cooling, leading to stress zones that affect durability and performance. A polariscope for plastic can reveal these stress zones as colored patterns, enabling manufacturers to adjust cooling rates or mould designs. Industries that produce clear plastic items like lenses, sheets, and medical equipment heavily rely on this inspection method to maintain safety and quality.

Why Use a Polariscope for PET Preform Inspection?

In the beverage and packaging industry, a polariscope for PET preform is necessary. PET preforms are small, tube-like pieces that are later blown into bottles. Any internal stress in the preform can lead to uneven bottle shapes, poor sealing, or reduced strength. The polariscope for PET preform makes sure that aligned molecules are aligned and eliminates defects in the early stage. That helps manufacturers from recalling their products and saves costs.

What Does A Polariscope Diagram Look Like?

The following components are usually part of a polariscope diagram:

- Light Source : This is usually a lamp, CFL or cSodium that gives steady and bright light.

- Polariser: The first filter placed after the light source. It makes the light waves move in one direction.

- Sample Stage: A small platform where the glass, plastic, or other sample is kept for checking.

- Analyser: The second filter, placed at a 90° angle to the polariser. It helps in showing the changes in light caused by stress inside the sample.

- Viewing Screen or Lens: The part through which we see the sample. It displays colourful patterns that reveal hidden stress inside the material.

- Rotational mechanism

In simplest terms, a polariscope is nothing but an optical device, but the impact it creates in the manufacturing units across industries is massive. Just by understanding its working principle, usage in various materials, and the benefits, you can increase the quality, safety and reliability of your products.

FAQs About Polariscope

Q1: What is the main purpose of using a polariscope in manufacturing?

Ans: The main polariscope uses is to detect hidden stress inside transparent materials like glass, plastic, and PET preforms, which our naked eyes cannot catch.

Q2: Is the polariscope a destructive testing method?

Ans: No, a polariscope stress analysis is completely non-destructive. The sample remains undamaged while being tested, making it ideal for checking finished products like bottles, lenses, or medical equipment before sending them to the clients and wholesalers.

Q3: How much does a polariscope cost?

Ans: The cost of a polariscope varies depending on its type and features. Different models offer varying capabilities for stress analysis, making pricing flexible to suit specific testing needs.

Looking for the best Polariscope price? Get high-quality Polariscope and Polariscope Strain Viewer at competitive rates from Presto Group. Ensure accurate stress analysis for glass and materials. Call +91 9210 903 903 or email info@prestogroup.com for a quote today!

Recent Blogs

- Compression Testing Machine Operating Method & Packaging Strength Testing Applications

- Bottle Cap Torque Tester Digital Torque Testing for Packaging Quality Control

- Controlled Humidity Chamber: Environmental Testing Methods, Applications & Packaging Testing Use Cases

- Spectrophotometer & Portable Spectrophotometer: Working Principle and Laboratory Applications

- Paint Tester & Coating Testing Equipment: Types, Testing Process, and Industrial Applications