- /

- Blog / Why Abrasion Resistance Matters in Packaging, Textiles, and Plastics

Why Abrasion Resistance Matters in Packaging, Textiles, and Plastics

In today’s competitive manufacturing world, abrasion resistance is a key property that determines how well a material stands up against daily wear and tear. Whether it's used in packaging, textiles, or plastics, understanding abrasion resistance helps manufacturers ensure product durability, reduce returns, and maintain customer trust.

Let’s dive into why abrasion resistance is so important, how it’s tested, and why businesses across various industries depend on it.

What Is Abrasion Resistance?

Abrasion resistance is all about how tough a material can be when it’s getting rubbed or scratched up. It’s like how your fave jeans don’t just shred after a couple camping trips. For textiles, it’s what keeps your couch fabric from looking fresh. In plastics, it’s why your phone case doesn’t look like it’s been in a blender after a month. And for packaging, it makes sure boxes don’t rip open when they’re shipped across the country.

This stuff matters big time ‘cause it affects how long something lasts, how it looks, and if it does its job right. If a material’s got weak abrasion resistance, you’ll end up with frayed clothes, scratched-up plastic, or busted packaging—not exactly a vibe for quality, ya know? Plus, it can mean returns or replacements, which ain’t cheap for companies.

Why Abrasion Resistance Matters in Different Industries

Alright, let’s break it down why this is clutch in packaging, textiles, and plastics:

1. Packaging

Packaging stuff—like cardboard boxes, plastic wraps, or those big sacks—gets roughed up during shipping, stacking, and handling. If it ain’t abrasion-resistant, it’s gonna tear, get weak, or just look trashed when it shows up at your door. That’s bad for the stuff inside and makes the brand look sloppy. You ever got a beat-up box? Doesn’t scream “trustworthy,” does it?

Abrasion-resistant packaging keeps your goods safe and makes sure the package looks legit, which keeps customers happy and cuts down on waste.

2. Textiles

In textiles, abrasion resistance is what makes or breaks how long your clothes or furniture last. Whether it’s your jeans, a couch, or some heavy-duty work gear, fabrics are always rubbing against something—your backpack strap on your shoulder or your pants on a chair. Fabrics with solid abrasion resistance in textile stuff hold up longer, don’t pill up, and keep looking dope. Like, outdoor gear—tents, jackets—needs to be tough to handle rocks and branches.

3. Plastics

Plastics are everywhere, man—your phone case, car dashboards, kitchen stuff. They gotta stay scratch-free to keep looking good and working right. Abrasion resistance in plastics means they don’t get all scuffed up over time, which is huge for stuff like medical tools or car parts. A scratched-up plastic ain’t just ugly—it can hold germs or get weaker.

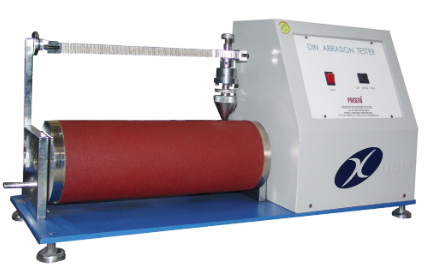

Abrasion Resistance Tester: The Essential QA Tool

An abrasion resistance tester simulates friction and wear on a sample and calculates how much the material has degraded. It’s a critical tool for R&D labs and quality control teams.

Key Features:

- Adjustable pressure and abrasion settings

- Suitable for a range of materials including rubber, plastic, and fabric

- Digital control panels for accurate readings

- Repeatable, standard-compliant test procedures

Using a reliable tester helps manufacturers produce consistent, high-quality products that can withstand real-life usage.

How Is Abrasion Resistance Measured?

To see how tough a material is, companies use abrasion resistance testers and standard tests that mimic real-life wear. These tests figure out how many rubs a material can take before it starts falling apart or how much of it gets worn away. Results come in stuff like “cycles” (how many rubs) or “weight loss” (how much material’s gone).

Common Abrasion Resistance Test Methods

There’s a bunch of ways to test this, depending on what you’re working with:

- Martindale Test: Big for textiles, this one rubs fabric in a circular motion with something rough. It’s perfect for checking abrasion resistance of fabric in clothes or furniture.

- Taber Abrasion Test: Used for plastics and rubber, it spins a sample under gritty wheels and checks how much it loses, either by weight or how it looks.

- Wyzenbeek Test: Another textile one, this uses back-and-forth rubbing to act like heavy use, like on a couch.

- Abrasion Resistance Test for Rubber: For rubber stuff, like tires or shoe soles, tests like DIN Abrasion measure how much gets scraped off on a rough surface.

Each test has its own abrasion resistance unit, like cycles, milligrams lost, or just a visual check. Depends on what industry you’re in.

Abrasion Resistance Formula

There ain’t one magic formula for all tests, but some use math to figure it out. Like, in the Taber test, they might calculate weight loss like this:

Abrasion Resistance = (Starting Weight − Final Weight) ÷ Number of Cycles

This shows how much material gets worn off per rub, so you can compare stuff easy.

Key Factors Affecting Abrasion Resistance

Not every material’s got the same grit. Here’s what affects how resistant it is:

- What It’s Made Of: Tough stuff like nylon or hard plastics usually beats softer materials.

- Surface Vibe: Smooth or slick surfaces hold up better than rough or holey ones.

- Coatings: Some plastics get a special coat, like polyurethane, to make ‘em tougher.

- Environment: Wetness, heat, or chemicals can mess with a material’s strength over time. .

Comparison of Abrasion Resistance Test Methods

| Test Method | Material Type | Motion Type | Common Uses | Unit of Measure |

| Martindale | Textiles | Circular | Clothes, upholstery | Cycles till it breaks |

| Taber Abrasion | Plastics, rubber, coatings | Rotary | Cars, gadgets | Weight loss (mg) |

| Wyzenbeek | Textiles | Back-and-forth | Furniture, curtains | Cycles till wear |

| DIN Abrasion | Rubber | Straight-line | Tires, shoe soles | Volume loss (mm³) |

Real-World Impact: Why Testing Matters

Testing abrasion resistance ain’t just some lab nerd stuff—it’s got real stakes. Like, a furniture company might use Wyzenbeek to make sure their couch fabric can handle kids jumping on it for years. A packaging company might use Taber to pick a plastic wrap that won’t rip during shipping. Without these tests, stuff could fall apart quick, leaving customers pissed and businesses losing cash.

Also, tough materials last longer, which is good for the planet. Less replacing means less waste, so it’s a win for everybody.

Challenges in Achieving High Abrasion Resistance

Abrasion resistance is dope, but it ain’t always easy to get. Here’s some hurdles:

- Pricey: Super-tough materials like Kevlar or fancy plastics cost a pretty penny.

- Heavy: Sometimes, abrasion-resistant stuff is bulkier, which sucks for lightweight packaging or gear.

- Looks: Treatments that make stuff tougher can change how it feels or looks.

Figuring out the balance is where the magic happens. Companies are always messing with new mixes and coatings to get it just right.

The Bottom Line

Abrasion resistance is like the unsung hero of packaging, textiles, and plastics. It’s what keeps your gear looking fresh, lasting forever, and holding up under pressure. Knowing why it matters and how it’s tested helps companies pick the right materials, and it lets us appreciate the science behind our tough stuff. Whether it’s a backpack that survives a road trip or a lunchbox that don’t scratch, abrasion resistance is what keeps quality real.

FAQs About Abrasion Resistance

1. What’s the best way to test abrasion resistance in textiles?

Martindale and Wyzenbeek are the top dogs for textiles. Martindale’s great for stuff like clothes with circular wear, while Wyzenbeek’s better for furniture with straight rubbing. Pick based on what the fabric’s used for.

2. How do I make a plastic product more abrasion-resistant?

Use harder plastics like polycarbonate, slap on a protective coating like polyurethane, or mix in some fillers when you’re making it.

3. What’s the diff between abrasion resistance and scratch resistance?

Abrasion resistance is about handling lots of rubbing over time, while scratch resistance is about not getting dinged up by one sharp hit. A material might be good at one but suck at the other.

4. Why’s abrasion resistance a big deal for packaging?

It keeps packaging from tearing or getting trashed during shipping, so the stuff inside stays safe and the brand looks pro.

Looking for the best Ink Abrasion Resistance Tester prices? Call us at +91 9210 903 903 or email info@prestogroup.com for a quick quote!

Recent Blogs

- Controlled Humidity Chamber: Environmental Testing Methods, Applications & Packaging Testing Use Cases

- Spectrophotometer & Portable Spectrophotometer: Working Principle and Laboratory Applications

- Paint Tester & Coating Testing Equipment: Types, Testing Process, and Industrial Applications

- Moisture Meter: Types, Working Principle & Applications in Industrial Labs

- Environmental,Pharmaceutical, and Research Laboratories in BOD Incubator