Our Valued Clients

Salt spray test chambers or cyclic test chambers are widely used in the automotive and metal products manufacturing industry to conduct the corrosion resistance test of the surface coatings. This quality assurance test will be used to determine whether the product will survive for a longer time when exposed to corrosive conditions or not. Thus, to make it easy for the manufacturers of the paint, plating, and coating industry to determine the corrosion resistance properties of their surface coatings, we at Presto have designed this highly advanced Cyclic Test Chamber.

Salt Spray Chamber is made as per ASTM B117 and JIS 2371 which is used for conducting Neutral Salt Spray Test or NSS test on Meta Surface Coatings. It is used for checking the resistance of the coating towards corrosive environment. The Salt Spray Tester generates an accelerated form of Salt laden environment inside which the specimen are tested for its quality.

Our Salt Spray Chambers come with three different types of specimen-holding fixtures. Those are as follows:

Choose the one that suits your sample testing needs!

Download E-Book

Registered Design Patent No. 244580

Availability: In stock

.jpeg)

The Presto CASS Tester has been designed strictly as per the relevant standard to assess the ability of rust proofed components to withstand corrosion due to atmospheric conditions. It is Triple Walled (with glass wool insulation).

.jpeg)

Presto Cyclic Corrosion Salt Spray Chamber – Worlds most Interactive and versatile corrosion test systems range available, synthesizing salt spray with other environmental conditions such as controlled humidity, ambient drying, air drying, dwell cycle and wetting / condensation.

Over time, various materials like metals and plated components can easily become corroded. This is why it's so important to conduct a salt spray test in order to check the corrosion resistance of coatings and materials used in the manufacturing of products such as fasteners.

Water Bath Digital is a proficient testing chamber which is utilized to inspect the modifications or damages occurring in the material's physical characteristics and to evaluate the actual working life of tested specimen at increasing temperature.

The Damp Heat Tester Chamber is a highly advanced environmental testing instrument designed to evaluate the durability, safety, and performance of products under prolonged exposure to high temperature and high humidity conditions. Widely used across industries such as solar, electronics, automotive, aerospace, telecommunications, polymers, and consumer appliances, this chamber helps manufacturers ensure their products can withstand tropical climates and moisture-rich environments without failure. it guarantees accurate and repeatable test results in compliance with IEC, ISO, JIS, and BIS standards. The Damp Heat Tester not only ensures global quality compliance but also provides industries with the confidence that their products will deliver long-term reliability and performance even in the harshest environments.

Humidity Chamber - Touch Screen with Data Logger is used for assessing the change in physical properties of the materials when there is a severe change in the environmental conditions like humidity. The machine is equipped with advanced touch screen panel and upgraded features. It comes with 3 coloured tower style alarm to alert the operator.

Humidity/Conditioning Chamber is a unique test cabinet designed to create temperature and relative humidity inside the chamber to detect the change in the physical characteristics of material and to ascertain the actual working life of testing device. PRESTO humidity chamber is designed as per standards ASTM D1776, ASTM D1776M-15.

Programmable Temperature & Humidity Test Chamber is the latest technology designed for evaluation of material, product and component's behaviour and its tolerance level in harsh weathering conditions including temperature and humidity.

Polymer products usually damage when exposed to various environmental conditions which are formed from the atmosphere. This directly affects the actual life of the product. Hence, it is necessary to test the quality of the polymers to calculate...

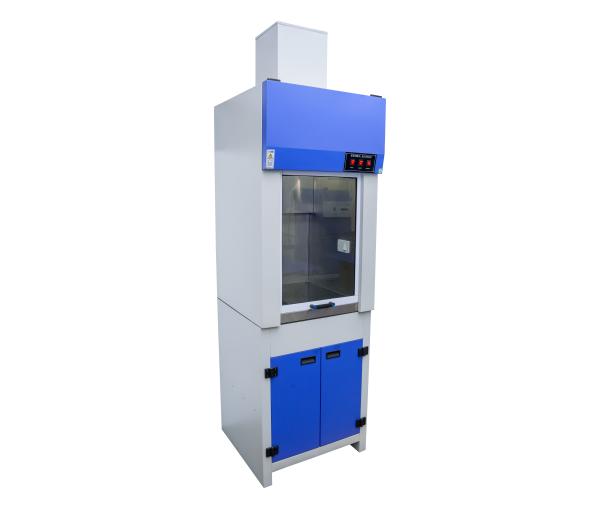

Laboratory fume hoods are designed to protect laboratory personnel by preventing contaminants such as chemical vapors, dust, mists and fumes from escaping into the laboratory environment.

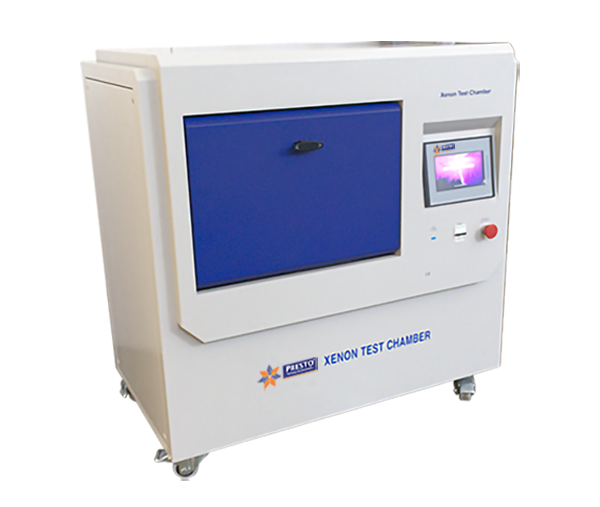

Presto offers different types of environmental testing instruments to create actual weather conditions of various kinds. One of the best environmental test equipment introduced by Presto is Xenon 866. The test equipment helps to examine the weather resistance...

Polymer materials are usually get damaged due to the natural environmental factors which form due to the atmosphere and earth's surface when it is used for years outdoor which directly affect the life of the products.

Hot Air Oven is a unique test cabinet designed to detect the change in the physical characteristics of the material and to ascertain the actual working life of testing device at elevated temperature. Works on Forced air circulation, thermal convection principle, suitable for Tests like heat deformation, compression set, heat resistance required in rubber and plastic industries.

Hot Air Oven - Touch Screen is a time-tested instrument to assess the change in physical properties of the materials with the change in temperature. This is an advanced model with complete touch screen control and upgraded features. It comes with 3 colors tower style alarm to alert the operator.

This test method covers the effects of elevated temperatures on the properties of a material. Testing is performed in air for a specified period at a specified temperature. Properties are measured prior to and after high temperature exposure.

Specially manufactured to perform humidity and temperature testing, Presto is pleased to introduce a wide range of Environmental Test Chambers. We possess one of the most exclusive lines of test cabinets to measure the working of a particular product in various temperatures. Our quality products are perfectly suited for labs where space limitations require a negligible footprint and can fulfill your humidity, altitude, and temperature related requirements.

Presto Environmental Test Chambers are expertly crafted to replicate natural environmental conditions, allowing industries to evaluate how their products perform under challenging temperature, humidity, and climatic variations. Recognized as one of India’s most trusted environmental test chamber manufacturers and suppliers, Presto Stantest Private Limited provides precision-engineered solutions that support sectors like automotive, aerospace, defense, electronics, packaging, and consumer goods and many other industries

Each chamber is designed with long-lasting materials with premium quality with global standards, intelligent control interfaces, and an operator-friendly structure easy to use also ensure consistent, reliable outcomes. Whether you require a small bench-top model or a large walk-in unit, Presto offers custom configurations that maintain high quality and performance standards, backed by dependable service and technical support.

Environmental Chambers for Materials Testing

Different materials react in unique ways when exposed to extreme weather or environmental changes. Presto’s Environmental Chambers for Materials Testing recreate these fluctuating conditions, enabling manufacturers to detect material weaknesses, study behavior, and ensure product durability before mass production. These chambers are vital for testing products’ long-term performance and maintaining compliance with international quality standards.

Custom Environmental Test Chambers

Every testing requirement is distinct, and so are Presto’s solutions. Our Custom Environmental Test Chambers are manufactured for clients to match specific temperature ranges, humidity levels, and product dimensions requirements. Whether you require multi-zone testing, larger chamber volumes, or special temperature gradients, Presto’s engineering team designs each system for peak accuracy, reliability, and ease of use.

After-Sales Service & Support

At Presto, customer satisfaction extends beyond delivery and installation. We ensure your equipment performs efficiently throughout its lifespan through comprehensive after-sales support. Our services include:

• Onsite maintenance and calibration

• Availability of genuine spare parts

• Remote troubleshooting assistance

• Annual service contracts and operator training

• Performance validation and certification support

Presto Stantest Pvt. Ltd. Environmental Test Chambers — ensuring product reliability through precision testing and superior engineering.

Trusting by the best, serving the best