Our Valued Clients

.jpeg)

The Presto CASS Tester has been designed strictly as per the relevant standard to assess the ability of rust proofed components to withstand corrosion due to atmospheric conditions. It is Triple Walled (with glass wool insulation).

Presto coating thickness gauge is the perfect instrument to use measure the expected life of coating. Widely used in paints and dry coating, it measures the dry film thickness very efficiently. Dry coating measurement is a very crucial prospect as it defines a lot about the process, cost and quality. Apart from that, the performance can be estimated in different working environments. It is a non-destruction form of testing and can be used for on-site inspection.

It is one of the best product to measure the coating thickness measurement of ferrous and non-ferrous coatings. Designed ergonomically to use in on-site inspection, its portable nature makes it easy to use. It has a bright LCD display for easy reading. The machine has very simple operation and does not require special skills to operate the instrument. It is used to determine the quality and life expectancy of the thickness coating.

Coating thickness gauge is widely used in measuring the coating of the surface. Used widely in metal industries, it can be efficiently used to measure the non-conductive coating over a non-ferrous surface. To protect the metal surfaces from corrosion, they are often coated with paint or metallic coating. To estimate the life and quality, coating thickness measurement in often done. Using a digital gauge eases the process and does not require special skill for this.

Presto's Profile Projector is robust measuring testing equipment which is widely used in PET & Preform Industries, quality assurance departments, machine shops and also in industrial testing laboratories.

The PRESTO Water Bath Digital (Rectangular - Double Walled, Stainless Steel) is a digital equipment, wherein both the inside and outside are made of high-grade corrosion resistant Stainless steel. It is used to incubate samples in hot water at high temperatures required in textile and microbiology industries.

(1).png)

Elevated temperatures can have a significant impact on the physical properties of many materials. Either it can deteriorate the quality of the product or will lead to product damage. This can have a major impact on the performance of products and structures made from these materials. Thus, it is important for product manufacturers to test the physical properties of the materials at elevated temperatures so as to determine their quality.

Presto manufactures Hot Air Oven Sterilizer, which is used to measure the effect of elevated temperatures on various types of materials such as textiles, rubbers, metal, yarn, paper and many more..

Presto Hot Air Ovens with Digital Temperature Controller are used to measure the effect of elevated temperatures on various types of materials like yarn, textile, plastics, rubber, paper, etc. Hence, it is mandatory to test the effect of ageing, heat resistance and heat deformation on the products that are manufactured in paper industry, rubber industry, and textile & yarn industry.

Programmable Temperature & Humidity Test Chamber is the latest technology designed for evaluation of material, product and component's behaviour and its tolerance level in harsh weathering conditions including temperature and humidity.

Salt Spray Chamber is made as per ASTM B117 and JIS 2371 which is used for conducting Neutral Salt Spray Test or NSS test on Meta Surface Coatings. It is used for checking the resistance of the coating towards corrosive environment. The Salt Spray Tester generates an accelerated form of Salt laden environment inside which the specimen are tested for its quality.

Our Salt Spray Chambers come with three different types of specimen-holding fixtures. Those are as follows:

Choose the one that suits your sample testing needs!

Download E-Book

Registered Design Patent No. 244580

Availability: In stock

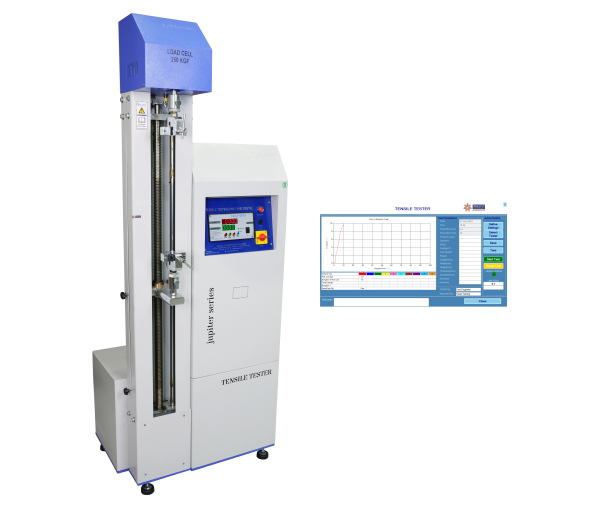

The Tensile Strength Tester for Adhesive Tapes is one of the best product to determine the actual adhesive strength of the tapes..

Presto manufactures the high-quality Tensile Strength Tester for Plastic Films that is used to evaluate the tensile strength of plastic materials used for plastic films..

Tensile testing is an important process for evaluating the strength, ductility, and toughness of materials. By determining a material's Young's modulus, tensile testing can also provide information about a material's stiffness.

The Tensile testing Machine is highly recommended for evaluating the tensile strength of products and materials. The equipment is based on the Constant Rate of Traverse (CRT) principle. It is equipped with an upper jaw and a lower jaw. Universal Tensile Testing Machine is a reliable piece of equipment which is widely used for checking tensile strength of a product/sample. One of the most common mechanical testing techniques used to determine tensile strength, this is a method wherein controlled tension is applied to a sample until it fully fails.

Thus, the material properties of the sample can be easily determined by this test. It involves measuring the force required to elongate a sample under test to breaking point. Using this test, manufacturers and quality managers are able to determine the core strength of their products.

Registered Design Patent No. 252611

Availability: In stock

Tensile strength is the stress at which a material breaks or permanently deforms. PRESTO Digital Tensile Tester is a state of the art, highly versatile equipment for checking the breaking strength of packaging related raw materials and finished products.

The Presto Ultra Low Temperature Deep Freezer is equipped with an air cooled compressor and CFC free refrigerators. These systems are installed to provide efficient cooling and consistent flow in the cabinet.

Ultra Low Deep Freezer - Touch Screen is used for assessment of physical characteristics of materials like rubber and plastic at very low temperatures. It is a time-tested machine for environmental testing and simulation of severe environmental conditions.

Polymer products usually damage when exposed to various environmental conditions which are formed from the atmosphere. This directly affects the actual life of the product. Hence, it is necessary to test the quality of the polymers to calculate...