Our Valued Clients

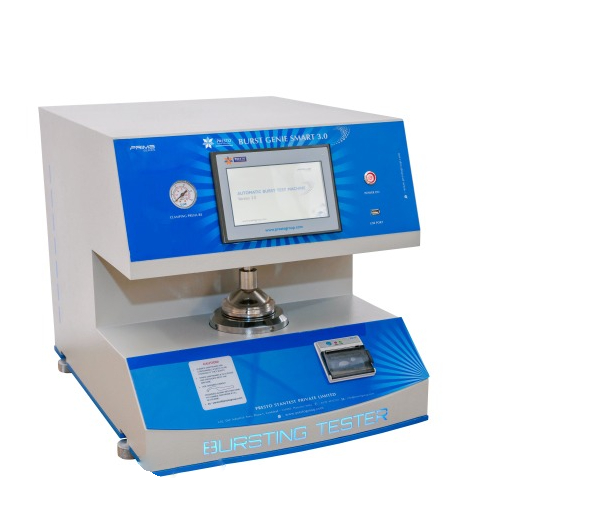

Bursting Strength Tester Genie Smart 3.0 is a reliable index of measurement of strength and performance of materials like paper, paper boards, corrugated boards and boxes, solid fiber boards, filter cloth, industrial fabric, leather and Rexene.

Bursting Strength Tester - Digital Pneumatic is provided with digital display and pneumatic clamping system for determination of bursting strength of paper, paper-board, solid fiber board and corrugated board and boxes. The equipment is widely...

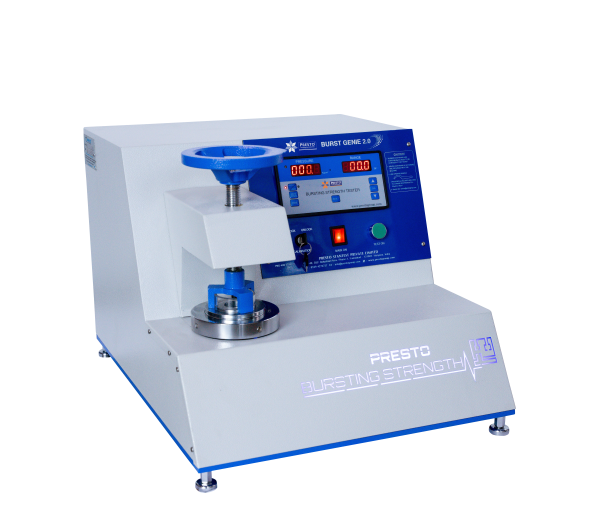

The force required for bursting or complete rupture of the board is measured through a Digital Indicator. The bursting strength defines the material's quality as compared to the others. Bursting Strength Tester Genie 2.0 provides a hydraulic pressure on the sample.

In the Presto Bursting Strength Tester, a hydraulic pressure is applied on the sample under test, using a neoprene diaphragm, on a circular area. So, a circular piece of the sample of the corrugated board is used for the test. A digital indicator with a range of 0 to 40 kg/ square cm, is utilized for the equipment.

Registered Design Patent No. 279109

Availability: In stock

It is measured by giving a hydraulic pressure through a rubber diaphragm on a circular area of the specimen of CBF under test conditions. The force required to burst or complete rupture of the board is measured through a Digital Indicator.

Bursting Strength Tester - Digital Pneumatic with Printer is the high-end model for estimating bursting strength of the materials like paper, corrugated fibre board, cloth, foil, etc. It is equipped with a thermal printer to print the observation immediately for future use. The machine is designed with pneumatic clamping to avoid any slippage of the sample.

The coefficient of Friction Tester - Digital Cum Computerised is a consistent tool to indicate the starting and sliding friction of plastic films and sheets when sliding over itself or other substance at specified test condition.

Coefficient of Friction Tester is a consistent tool to indicate the starting and sliding friction of plastic films and sheets when sliding over itself or other substance at specified test condition.

Registered Design Patent No. 341519-003

.png)

The Presto Dart Impact Tester is used for determining the impact of a free falling dart on a plastic film. The energy of the falling dart causes the film to fail under specified conditions. The dart has a hemispherical head and is held by a strong electromagnetic dart holder.

In stock

Presto's Dart impact tester - HMI is a high-quality testing instrument, used in different packaging industries, to measure the strength of the plastic films to withstand the various forces levied on it. The instrument is provided with an electromagnetic...

The gloss meter is available in different geometries to measure the specular reflection gloss of a surface or a material. The Gloss Meter Tri-angle is used to determine the gloss on a surface and measures the amount of reflected light.

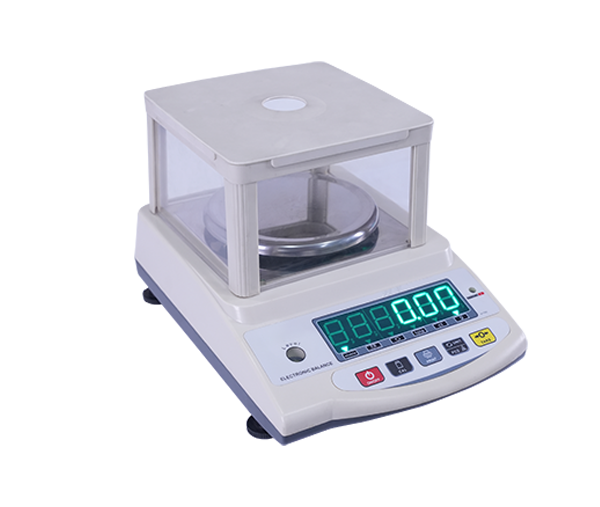

The Digital GSM balance is one of the highly effective and accurate laboratory testing equipment that is used to measure the weight of materials including paper, paperboard, solid fiberboards and corrugated boxes. This paper gsm checking machine ensures that users can get precise testing results for testing the grammage of products.

PRESTO Round Cutter for Grammage GSM Round cutter is useful for precise circular cutting to check the grammage of samples. The sample cutter cuts out a circular specimen of 100? Which is exactly 1 / 100th of a square meter, rapidly and accurately.

Heat Sealer Prima is a consistent tool used to perform sealing on flexible packaging products and other thermoplastic materials using pressure and heat by maintaining high temperatures. A heat sealer is used to measure the heat seal performance of composite films.

Availability: In Stock

Shipping Area: Throughout the world

Heat Sealer is a consistent tool used to perform sealing on flexible packaging products and other thermoplastic materials using pressure and heat by maintaining high temperatures. PRESTO Heat Sealer is manufactured under various Test Standards such as ASTM F 2029.

Heat Sealer is a consistent tool used to perform sealing on flexible packaging products and other thermoplastic materials using pressure and heat by maintaining high temperatures.

Presto Adhesion Strength Tester is used to quantify the permanence of adhesion or peel ability of self- adhesive pressure sensitive materials. Peel adhesion is defined as the force required for removing a pressure sensitive coated material.

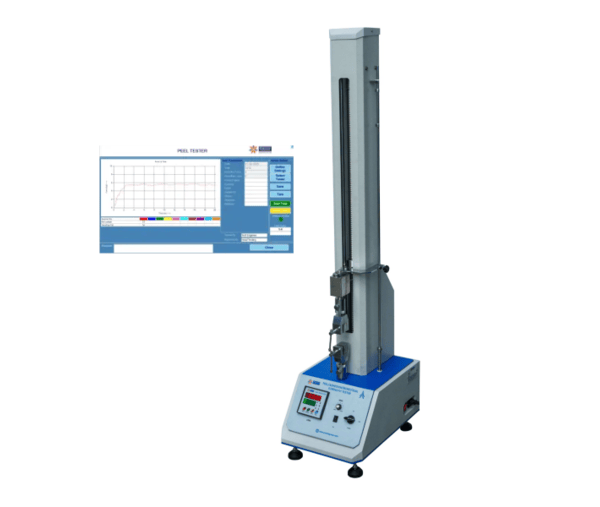

Peel Bond Strength Digital Tester is a standardized test machine, which is widely used to conduct accurate peel/seal strength test for adhesive materials. Suitable for measuring the stability of adhesives like tape or glue, it is a reliable quality control equipment. It is used for checking the ability of the sample to get peeled off from a surface. The testing equipment is designed and manufactured according to ASTM D903 standard.

Presto Peel Strength Tester has a display screen which is based on a hi-tech microprocessor that converts force applied into numeric values. So, the peel adhesive strength value that is measured can be directly viewed on the screen. Application force is controlled uniformly; this is done in order to ensure equal distribution of pressure, all over the test sample.

Registered Design No. 361206-003

Availability: In stock

Peel Adhesion/Bond/Seal Strength Tester is a consistent tool to quantify the permanence of adhesion or peel ability of a self-adhesive pressure sensitive materials. Used for checking the Peel, Adhesion, Bond, Seal Strength testing for Plastic Films and Foil.

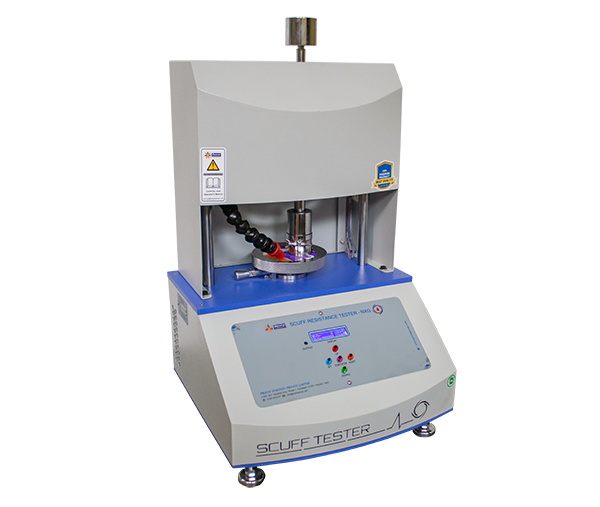

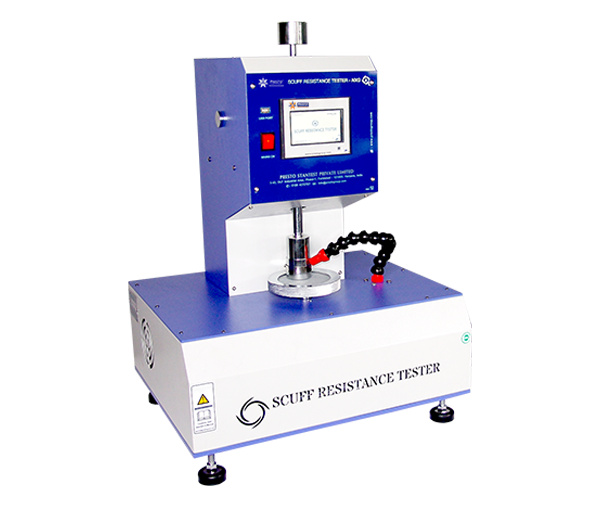

The term scuffing is the rubbing of two materials against each other. Scuff Resistance Tester is used to evaluate the rub resistance (i.e. the damage which has taken place through rubbing) of labels and general printed matter.

In stock

Scuff Resistance Tester is a unique test instrument to determine the color transfer from printed or coated material against rubbing. Scuff resistance testing can reveal how well a material will hold up against abrasion, rubbing, and scratching. This information is critical in industries such as packaging and printing where there is a vast use of labels and other printed materials.

Scuff testing of labels and other printed materials is used to determine their resistance to abrasion, scratching, or rubbing. This type of testing is essential for ensuring that the labels and printed materials can withstand handling and transportation without losing their legibility, durability, or aesthetic appeal.

The Tensile testing Machine is highly recommended for evaluating the tensile strength of products and materials. The equipment is based on the Constant Rate of Traverse (CRT) principle. It is equipped with an upper jaw and a lower jaw. Universal Tensile Testing Machine is a reliable piece of equipment which is widely used for checking tensile strength of a product/sample. One of the most common mechanical testing techniques used to determine tensile strength, this is a method wherein controlled tension is applied to a sample until it fully fails.

Thus, the material properties of the sample can be easily determined by this test. It involves measuring the force required to elongate a sample under test to breaking point. Using this test, manufacturers and quality managers are able to determine the core strength of their products.

Registered Design Patent No. 252611

Availability: In stock